A railway track grinding amount and profile detection device

A technology for railway tracks and detection devices, which is applied to measurement devices, grinding machines, and parts of grinding machine tools, etc., can solve the problems of single measurement data, inability to unify measurement benchmarks, and inability to eliminate the influence of rail bottom slopes, so as to improve detection efficiency, The limit is reliable and the effect of reducing the influence of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

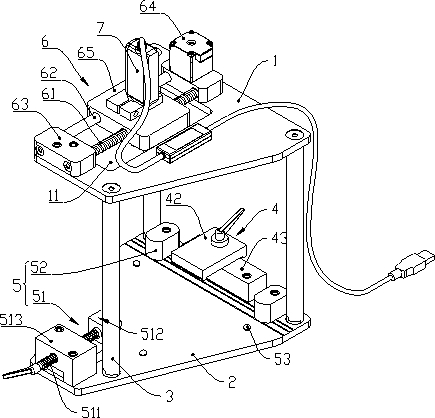

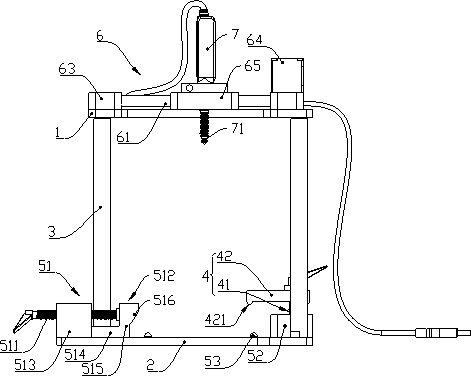

[0046] refer to figure 1 A railway track grinding amount and profile detection device includes: a mounting frame, a positioning clamping assembly and an adjustable detection assembly arranged on the mounting frame.

[0047] The mounting frame includes: an upper fixed plate 1, a lower reference seat 2, and a support column 3 arranged between the upper fixed plate 1 and the lower reference seat 2. The support column 3 is detachably connected to the lower reference seat 2. In this embodiment, The upper fixed plate 1 and the lower reference seat 2 are plate-like structures of isosceles trapezoid, and there are three support columns 3, which are arranged at the left and right ends and the upper end of the lower bottom of the isosceles trapezoid respectively. The upper end of the support column 3 is fixed on the upper fixed plate 1, and the lower end of the support column 3 is detachably clamped on the lower reference seat 2. The length of the support column 3 should be greater than...

Embodiment 2

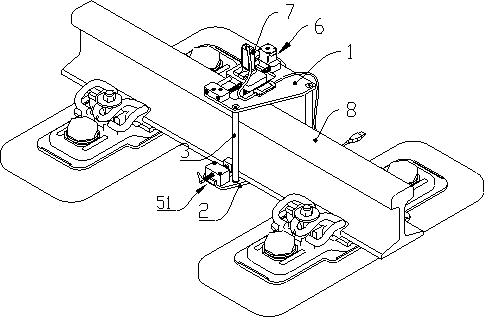

[0054] refer to Figure 5 The difference between this embodiment and Embodiment 1 is that the shapes of the driving screw 61 and the light guide rod 62 in the automatic feeding guide rail device 6 are set in an arc shape protruding away from the lower reference plane 1, and the contact The detection probe of the type rail surface profile detector is always along the radial direction of the arc, so when the mounting base 63 moves on the light guide rod 62, the detection probe of the contact type rail surface profile detector can be aligned with the rail surface to be tested. It has a certain angle, so it can measure the data of different angles of the rail surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com