Positioning tool and positioning equipment

A technology for positioning tooling and positioning plates, which is applied to workpiece clamping devices, manufacturing tools, etc., can solve problems such as unexpected situations, low labor efficiency, and low precision, and achieve safety accidents, simple structure, and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

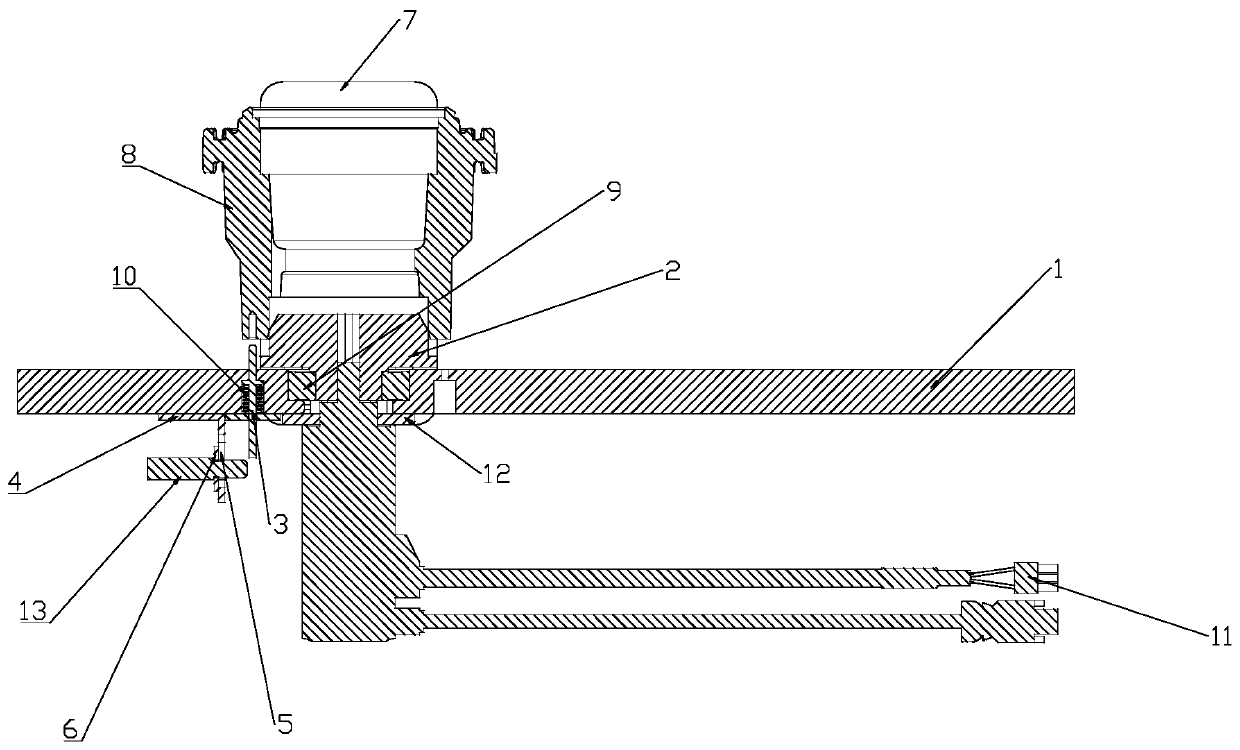

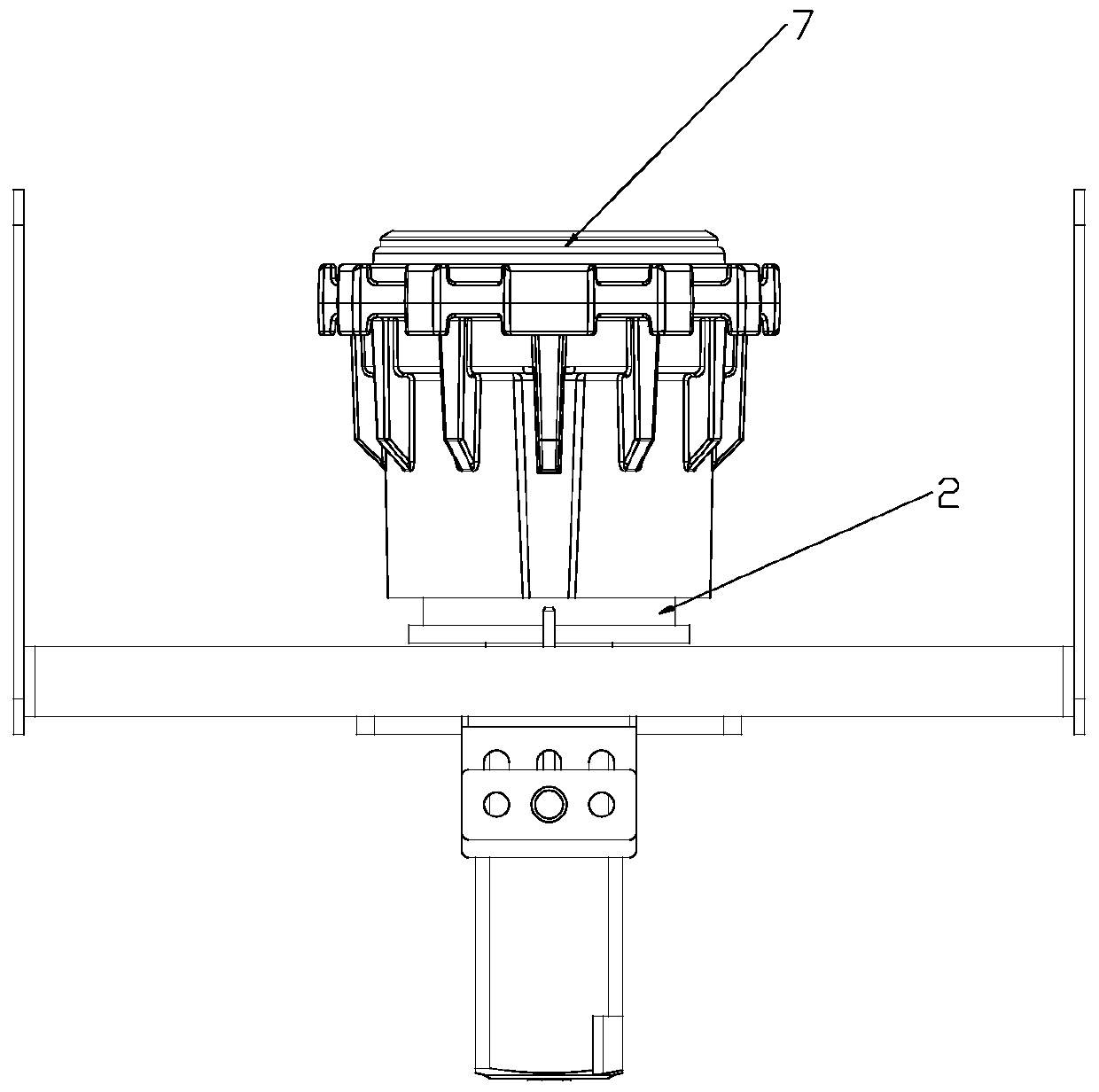

[0021] In order to better understand the purpose, structure and function of the present invention, below in conjunction with appendix Figure 1-2 , to further describe in detail a positioning tool of the present invention.

[0022] The present invention provides a positioning tool for positioning the workpiece 8. The existing positioning of the workpiece 8 is performed manually. Now, a positioning tool is provided to place the workpiece 8 on the positioning tool, and automatically position and align the workpiece 8 to achieve precise positioning of the workpiece 8.

[0023] Such as Figure 1 to Figure 2 As shown, the present invention provides a positioning tool, including a positioning plate 1, a positioning assembly and a detection assembly are arranged on the positioning plate 1, the positioning assembly is connected with a drive structure, a workpiece 8 is placed on the positioning assembly, and when the detection assembly detects that the workpiece 8 is not Aligned with ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap