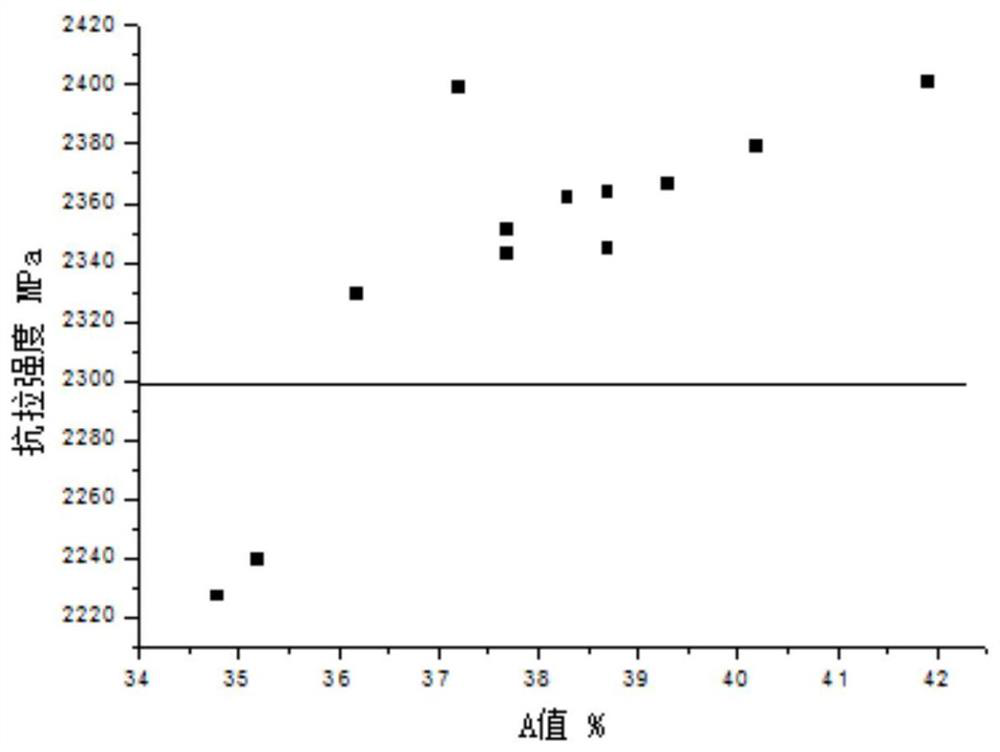

A kind of ultra-high-strength spring steel with excellent hydrogen-induced delayed fracture resistance and production method thereof

A technology of delayed fracture and ultra-high strength, which is applied in the field of spring steel, can solve the problems of reduced fatigue life, the development of ultra-high-strength toughness steel has not yet started, and the deterioration of plasticity and toughness, and achieves excellent delayed fracture resistance and fatigue performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

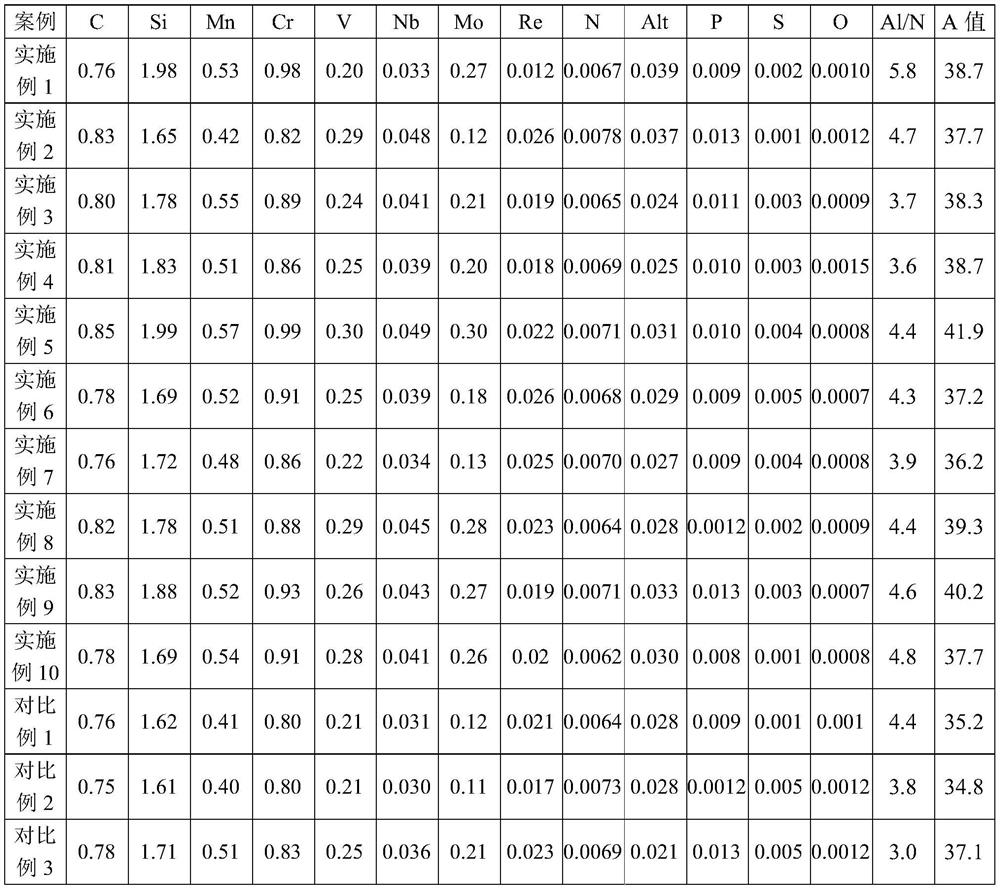

[0045] The present invention will be described in detail below in conjunction with examples.

[0046] The present invention adopts the wire rod of specific composition, and embodiment and comparative example composition are shown in Table 1, and production process is as follows:

[0047] Electric furnace smelting: Oxygen is fixed before tapping, and steel is left in the tapping process to avoid slag;

[0048] LF furnace: C, Si, Cr, Mn, V, Nb, Re, Mo and other elements are adjusted to the target value;

[0049] Vacuum degassing: pure degassing time ≥ 15 minutes, fully remove [H];

[0050] Continuous casting: the target temperature of molten steel in the tundish is controlled at 10-40°C above the liquidus temperature, and continuous casting of 250mm×250mm blooms;

[0051] Billet opening: 250mm×250mm bloom heating→rolling to 150mm×150mm billet→stack cooling, control the soaking temperature of the heating furnace at 1220-1250℃, and the total heating time is ≥230min;

[0052] Wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| fatigue strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap