An optimization method for dense cutting and temporary plugging fracturing in a shale horizontal well section

A technology of horizontal well section and optimization method, which is applied in design optimization/simulation, earthwork drilling, sealing/packing, etc., can solve the problems of unclear re-expansion of suppressed fractures, difficulty in construction design, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

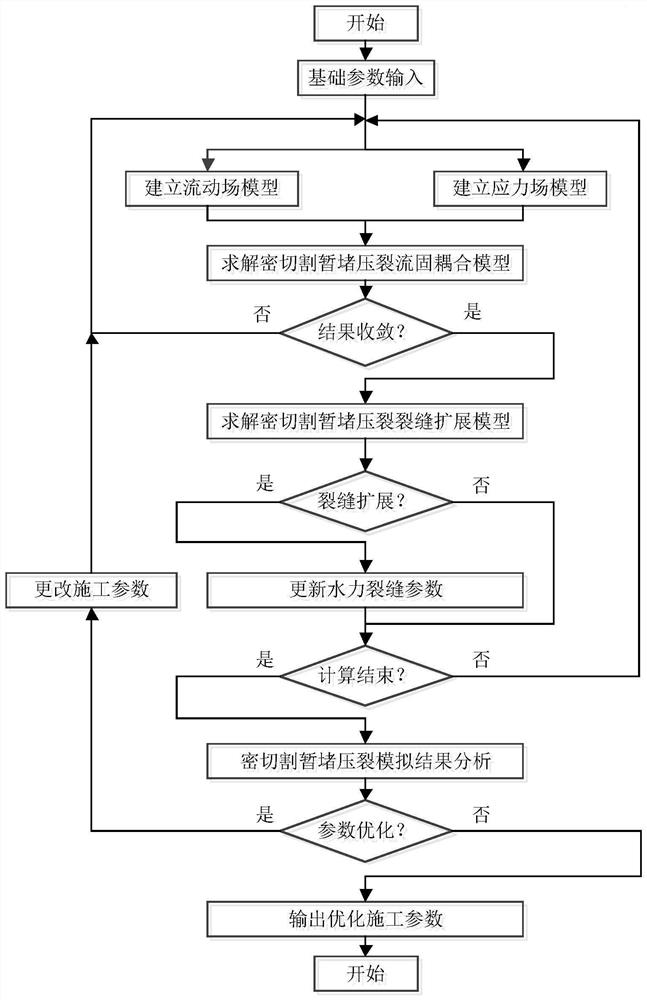

[0039] Such as figure 1 As shown, the main content of the present invention is a method for optimizing the construction of dense cutting temporary plugging and fracturing in a shale horizontal well section. The main steps include:

[0040] Step S10, obtaining reservoir parameters, well completion parameters, and fracturing operation parameters;

[0041] Among them, reservoir parameters include reservoir thickness, Young's modulus, shear modulus, Poisson's ratio, horizontal maximum principal stress, horizontal minimum principal stress, fracture toughness of reservoir rock, and average length, angle, density, Tensile strength, shear strength, friction coefficient of fracture surface, etc.; completion parameters include perforation cluster number, perforation number and perforation diameter; construction parameters include fracturing fluid rheological parameters, construction displacement, etc. In order to illustrate the optimization method of the present invention, this example...

Embodiment 2

[0076] In order to further illustrate the optimization method of the present invention, the most optimized parameter of construction displacement is still used as an example, and the second embodiment is modified on the basis of the first embodiment, the number of crack clusters is increased from five clusters to seven clusters, and the dense cutting is temporarily carried out. Plugging and fracturing construction displacement optimization.

[0077] Step S10, obtaining reservoir parameters, well completion parameters, and fracturing operation parameters;

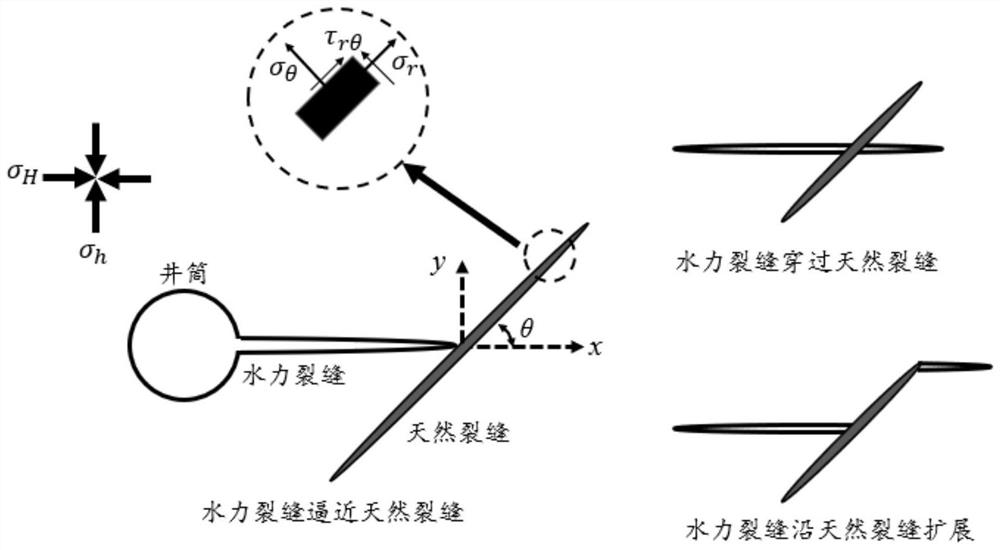

[0078] The parameters in Example 2 are shown in Table 1. Only the number of clusters of fractures is changed, which is set to seven clusters. The distribution of natural fractures remains unchanged, and the number of clusters is still used. figure 2 distribution pattern in .

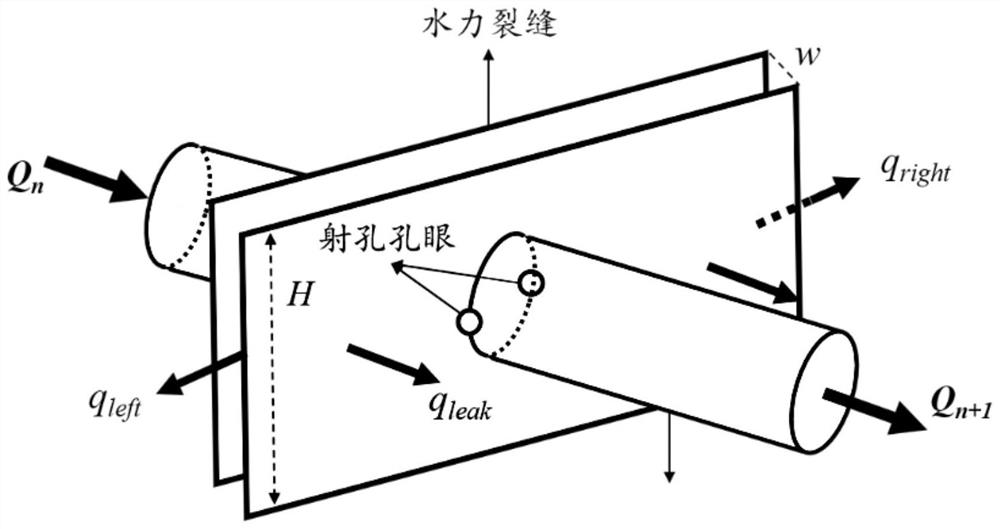

[0079] Step S20, establishing a hydraulic fracturing fluid-solid coupling model through the displacement discontinuity method;

[0080] The establi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap