A new type of carbon dioxide liquefaction device and preparation method

A carbon dioxide and liquefaction device technology, applied in liquefaction, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of violent boiling, affecting heat exchange effect, unstable liquid level, etc. Small footprint and small equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solution in the embodiment of the invention in conjunction with the accompanying drawings in this embodiment,

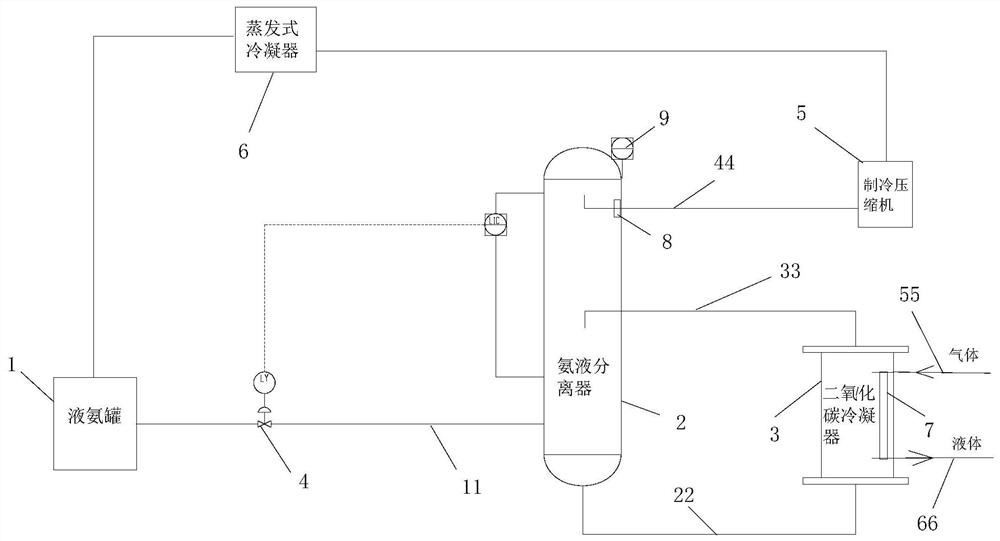

[0020] see figure 1 As shown, the present invention also provides a novel carbon dioxide liquefaction device, comprising a liquid ammonia tank 1, an ammonia liquid separator 2 and a carbon dioxide condenser 3, and the liquid ammonia in the liquid ammonia tank 1 is transported through a first pipeline 11 through a regulating valve. 4 is sent to the bottom of the ammonia liquid separator 2, and the bottom of the ammonia liquid separator 2 is transported to the bottom of the carbon dioxide condenser 3 through the second pipeline 22; The third pipeline 33 with the elbow opening facing downward is delivered to the middle inlet valve of the ammonia liquid separator 2; the ammonia gas at the upper part of the ammonia liquid separator 2 chamber is delivered to the fourth pipeline 44 through the upward op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com