A mold for long cylindrical plastic parts with rotatable core

A technology for cores and plastic parts, which is applied in the field of molds for long cylindrical plastic parts, and can solve problems such as long production time, large space occupied by equipment, and large mold opening distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

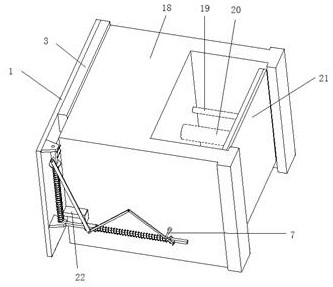

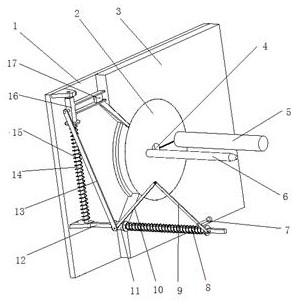

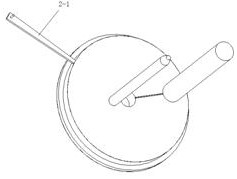

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below with reference to the accompanying drawings:

[0024] The present invention provides a mold for a rotatable core for a rotating core, which causes a large-scale spacing of the plastic parts when the current mold is injection molded, and the mold operation requires a longer rail, indirect It causes the equipment to occupy a large factory space, while the long-distance opening engagement mold leads to the total time of the plastic parts. Designing such a mold type mold with a rotating core, a rotating core, that is, when the mold is opened, the core is detached from the cavity, i.e., rapid rotating the core rotation disc, so that the core axis is The cavity hole axis is misplaced in the moving model. At this time, there is no need to continue the mold, you can introduce the plastic parts. Because the core has been opened, the launched plastic parts will not interfere with the core, reducing the molding stroke. An...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com