Construction support frame automatic cleaning and conveying device

An automatic cleaning and conveying device technology, applied in the direction of conveyors, transportation and packaging, loading/unloading, etc., can solve the problems of time-consuming and laborious cleaning of cement, troublesome cleaning of support frames, and reduced loading efficiency, so as to improve efficiency and avoid inefficiency , the effect of automatic cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

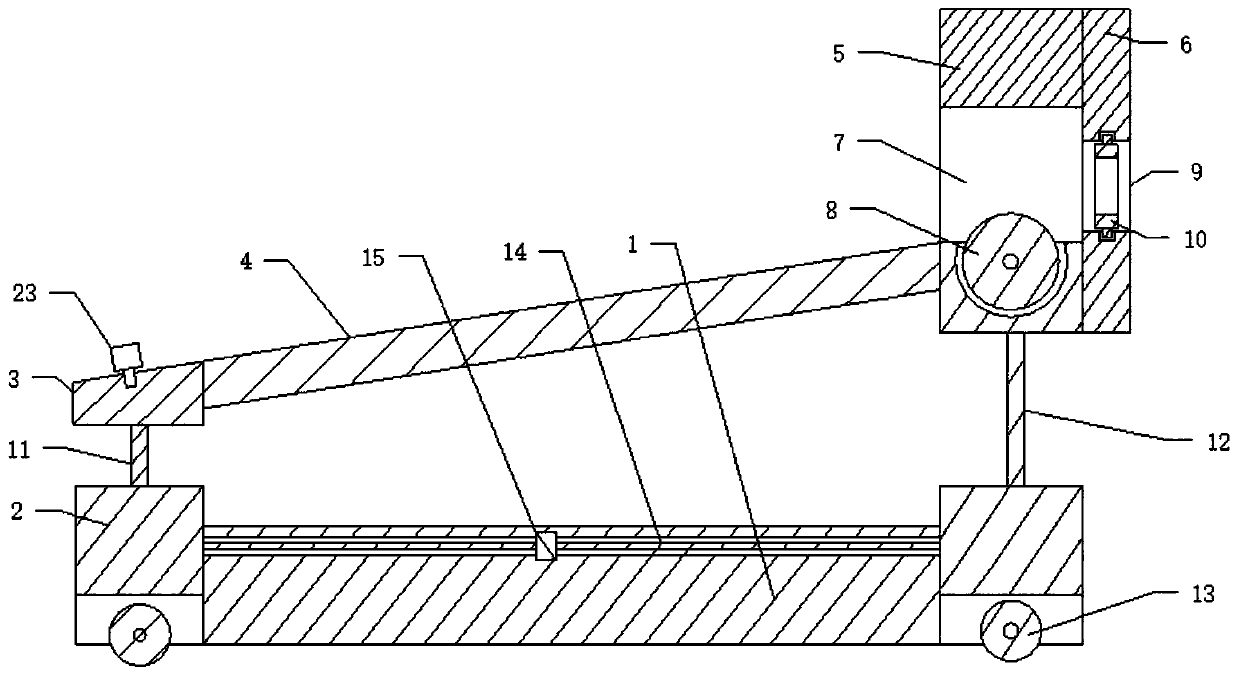

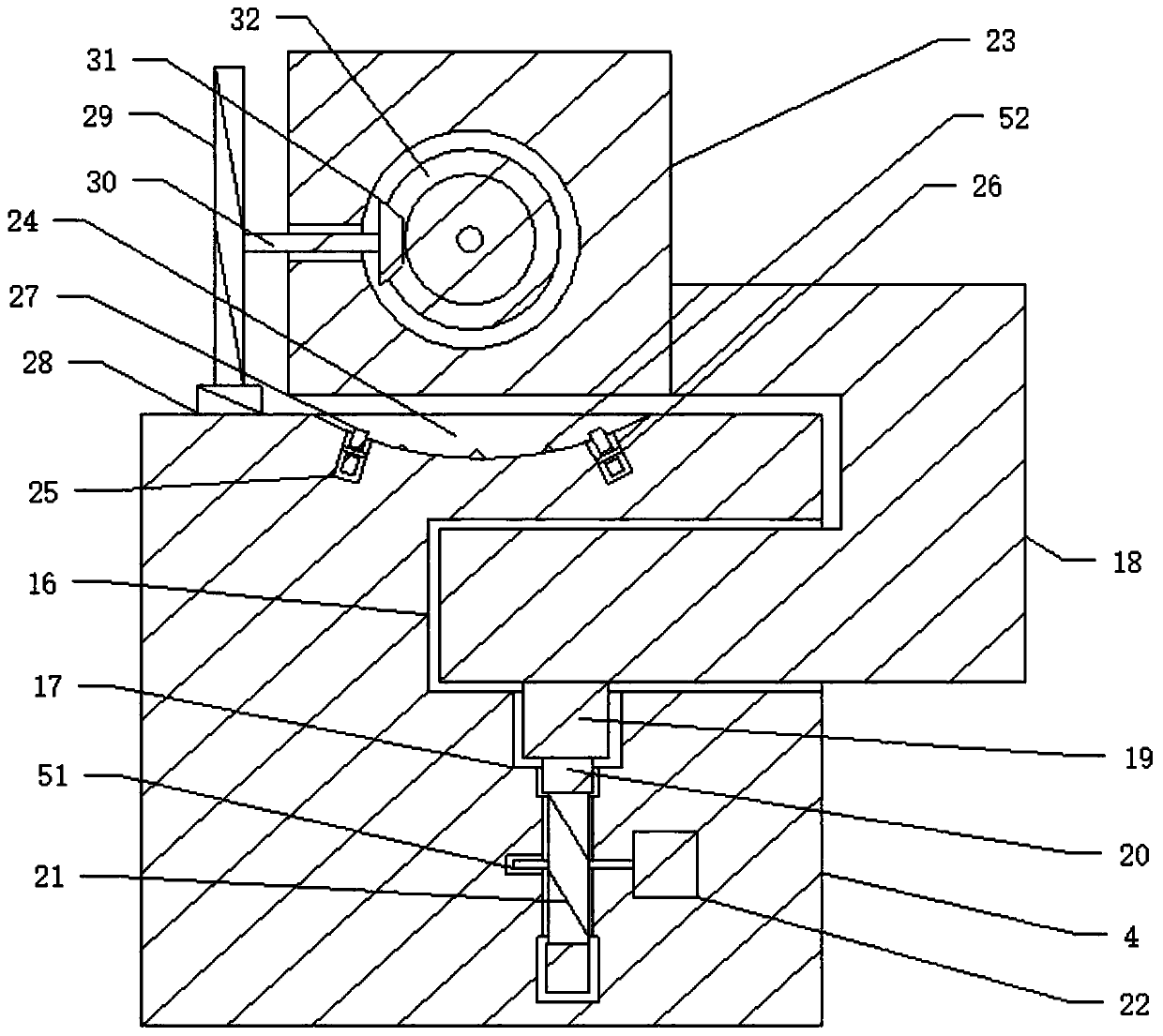

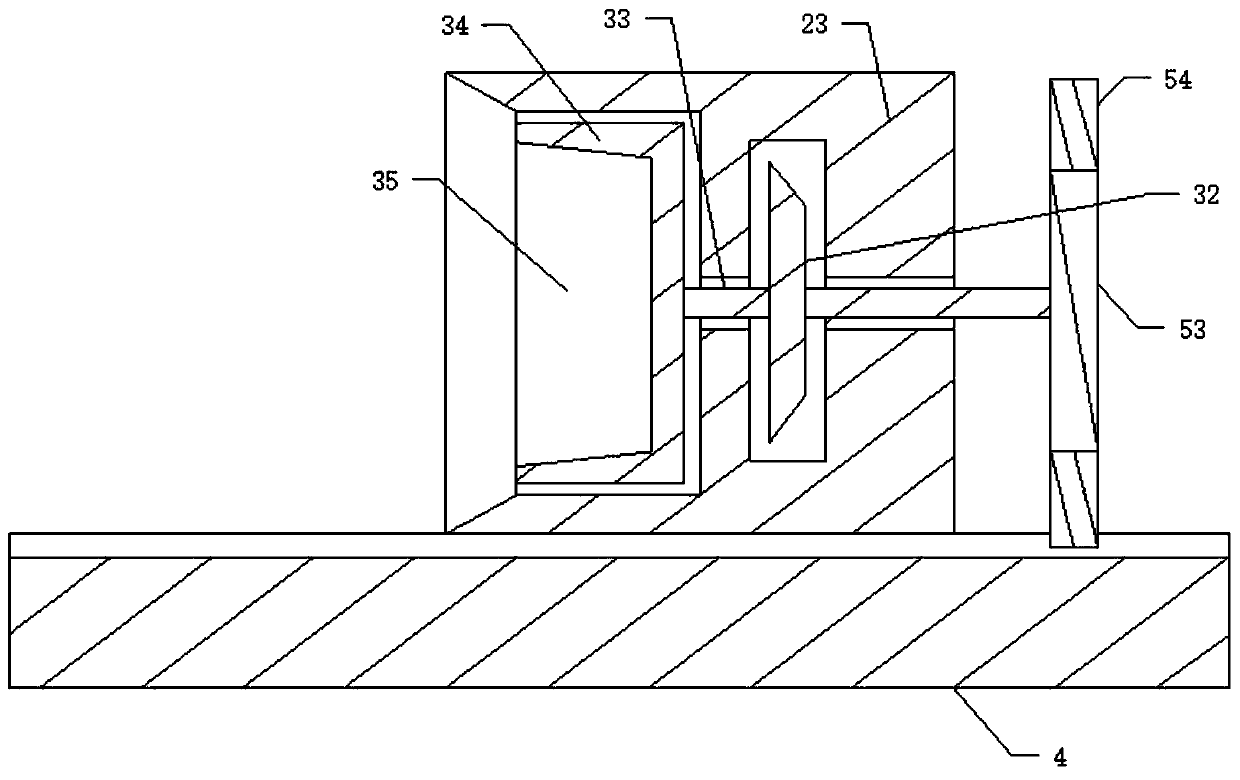

[0025] like Figure 1 to Figure 5 As shown, an automatic cleaning and conveying device for a building support frame includes a support base 1, two rotating rollers 13 are respectively provided at both ends of the support base 1, and a Lifting pillar 2, one end lifting pillar 2 is provided with a second threaded rod 12 for lifting and sliding, and the other end lifting pillar 2 is provided with a first threaded rod 11 for lifting and sliding. A first support 3 is fixedly connected, a second support 5 is fixedly connected on the second threaded rod 12, and a conveying frame is arranged between the first support 3 and the second support 5 4 are connected correspondingly, a sliding sliding module 18 is provided on the conveying frame 4, and a pushing module 23 is arranged on the sliding module 18, and a driving turntable 34 of self-rotation is arranged on the pushing module 23, and the driving A steel pipe is clamped on the turntable 34 , and cleaning teeth 52 corresponding to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com