A safety protection structure of a rectifier for electrophoresis

A safety protection and rectifier technology, which is applied in the field of rectifiers, can solve the problems of automatic cleaning of the filter, reduce the stability of equipment operation, and affect the heat dissipation of equipment, so as to reduce labor costs, avoid stalls, and improve efficiency.

Active Publication Date: 2022-05-31

扬州中宏电力科技有限公司

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] Aiming at the deficiencies of the prior art, the present invention provides a safety protection structure for a rectifier for electrophoresis, equipped with a cleaning mechanism that can be automatically triggered, and the cleaning mechanism can automatically clean the filter plate, maintaining the operation stability of the equipment and reducing labor costs at the same time It solves the problem that the filter cannot be cleaned automatically, resulting in excessive accumulation of dust, which affects the heat dissipation of the equipment, requires manual cleaning at regular intervals, reduces the operation stability of the equipment, and increases the labor cost.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

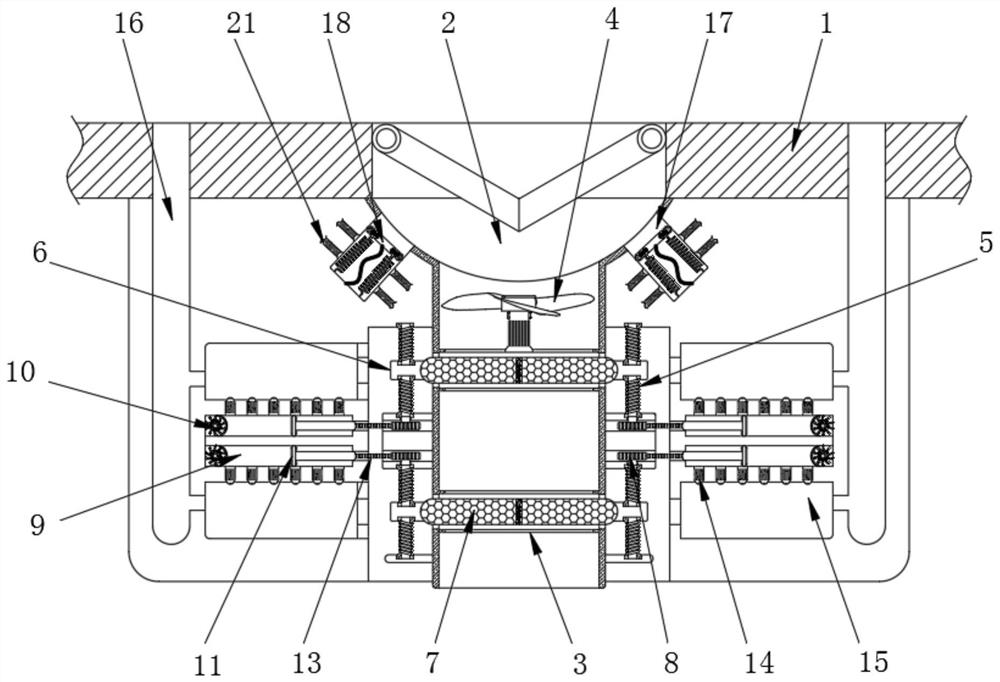

[0038] The side wall of the piston 11 is fixedly connected with a push rod 12, and one end of the push rod 12 away from the piston 11 is fixedly connected with a rack 13,

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

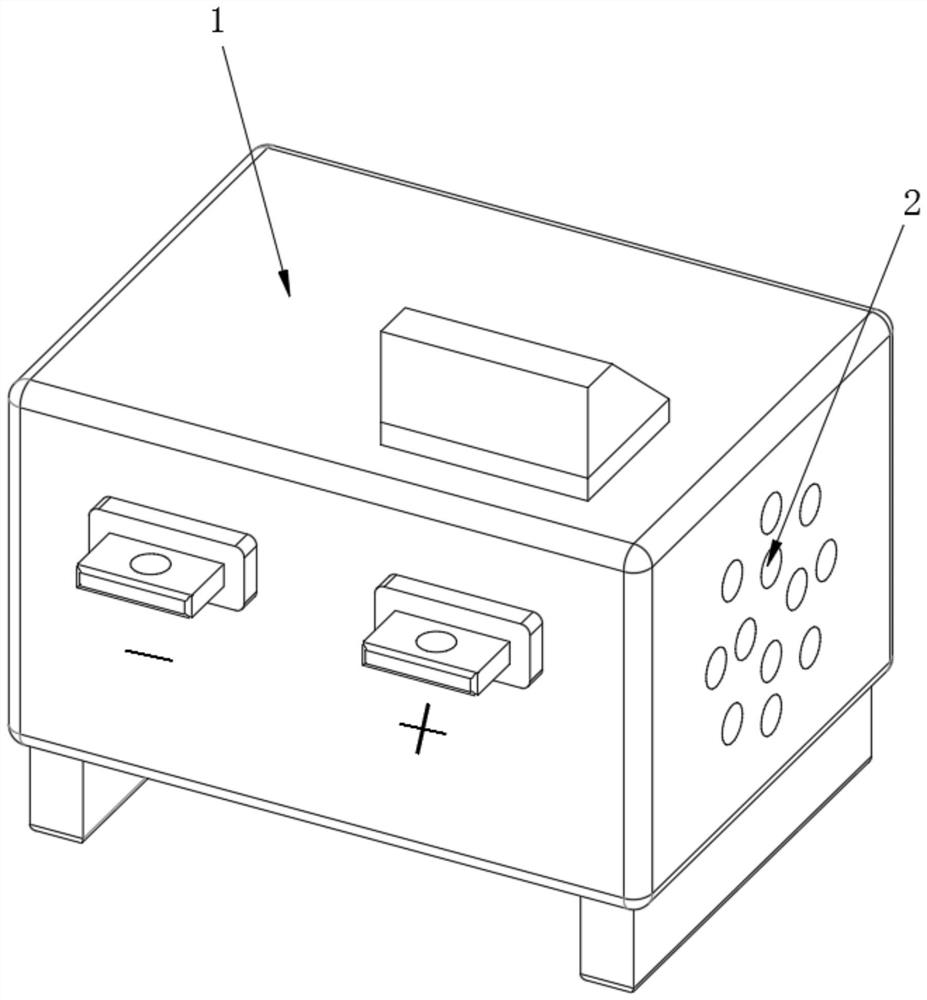

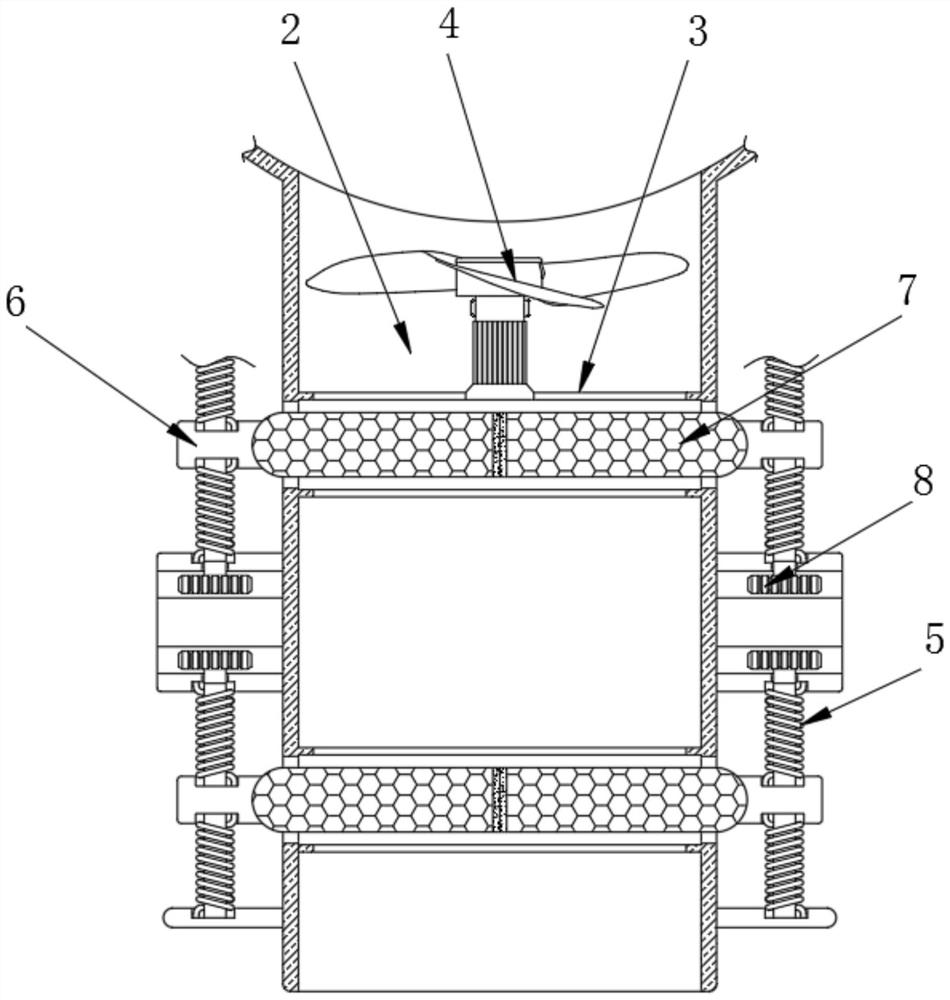

The invention relates to the technical field of rectifiers, and discloses a safety protection structure of a rectifier for electrophoresis, which includes a frame, an air inlet is opened on the side wall of the frame, and a support frame is fixedly connected to the inside of the air inlet. The top of the support frame is rotatably connected with fan blades, and the side of the frame close to the air inlet is rotatably connected with a spring rod, the surface of the spring rod is fixedly connected with a support rod, and the side of the support rod is fixedly connected with a filter plate. The end of the support rod is fixedly connected with a gear, and the side of the frame close to the spring rod is provided with a liquid tank, and the bottom inside the liquid tank is fixedly connected with a liquid pump, and the surface is cleaned by a nozzle, and the waste after cleaning is The liquid can be discharged from the inside of the equipment through the liquid drainage tank, so as to achieve automatic cleaning when the filter mechanism is blocked, avoid equipment stoppage, improve the stability of equipment operation, and reduce labor costs during cleaning.

Description

A safety protection structure of a rectifier for electrophoresis technical field [0001] The present invention relates to the technical field of rectifiers, in particular to a safety protection structure of a rectifier for electrophoresis. Background technique In the interior of the factory, it is necessary to use a rectifier to meet the needs of equipment work, because the rectifier is generally installed in the In the natural environment, impurities and sundries in the air can easily enter the interior of the equipment through the ventilation device, so it is necessary to Install a protective device on the vent outlet. The current rectifier vent protection device often prevents the entry of dust by adding a filter screen, but the The filter cannot be cleaned automatically, resulting in excessive accumulation of dust, which affects the heat dissipation of the equipment, and needs to be manually cleaned regularly. Cleaning reduces the operating stability of the equi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H02M7/00H02M7/02B01D57/02B01D46/12B01D46/79

CPCH02M7/003H02M7/02B01D57/02B01D46/12

Inventor 潘宏兵潘阳

Owner 扬州中宏电力科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com