Triggering device of an extinguishing system

A fire extinguishing system and equipment technology, applied in mechanical equipment, fire rescue, engine components, etc., can solve problems such as inability to suppress explosions, short trigger time, etc., reduce equipment maintenance and inspection costs, reduce system friction, The effect of reducing complexity and error-proneness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

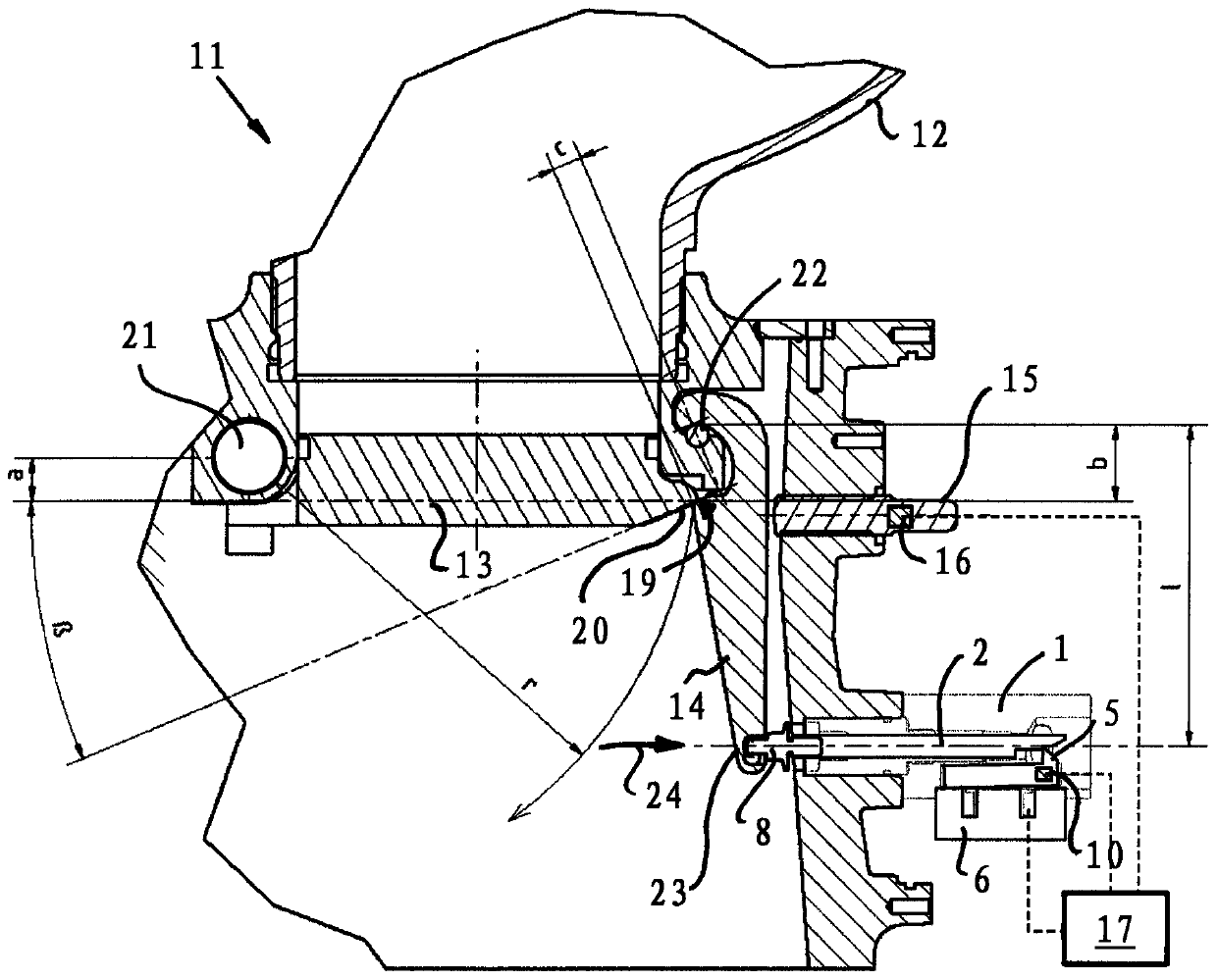

[0029] figure 1 A cross section of the fire extinguishing system 11 of the present invention is shown. An extinguishing agent container 12 is closed in a manner known per se with a closure mechanism 13 designed as a flap. The extinguishing agent container 12 is pressurized and filled with extinguishing agent. A powder containing sodium bicarbonate powder, for example, can be used as an extinguishing agent, the extinguishing agent container being brought to a system pressure of approximately 60 bar with nitrogen. The closing mechanism 13 is locked by means of a lever-shaped locking element 14 . In this case, the locking part 14 presses with a locking surface 19 against a contact surface 20 of the closure member 13 .

[0030] The size and relative arrangement of the center of rotation of the pivot bearing 21 of the closure structure 13 and the center of rotation of the lever bearing 22 of the locking element 14 of the contact surface between the locking surface 19 and the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com