A kind of coating method for growing second generation high temperature superconducting tape barrier layer composite film

A technology of high-temperature superconducting tape and barrier layer, which is applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., to reduce equipment costs, reduce system components, and increase the coating area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

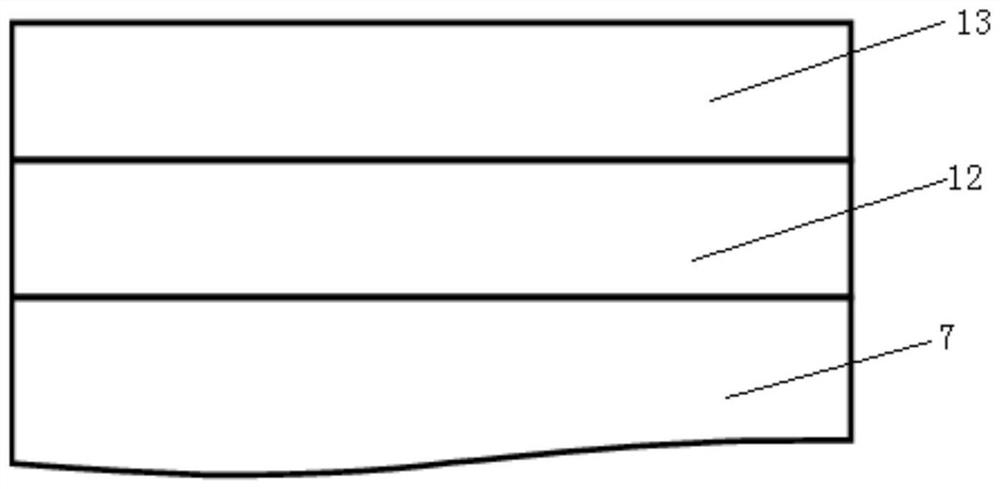

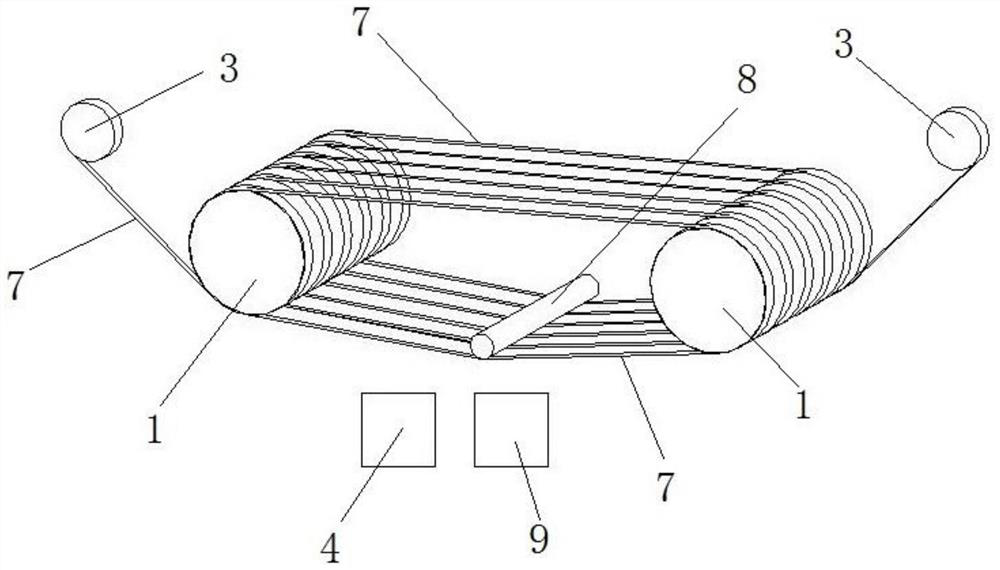

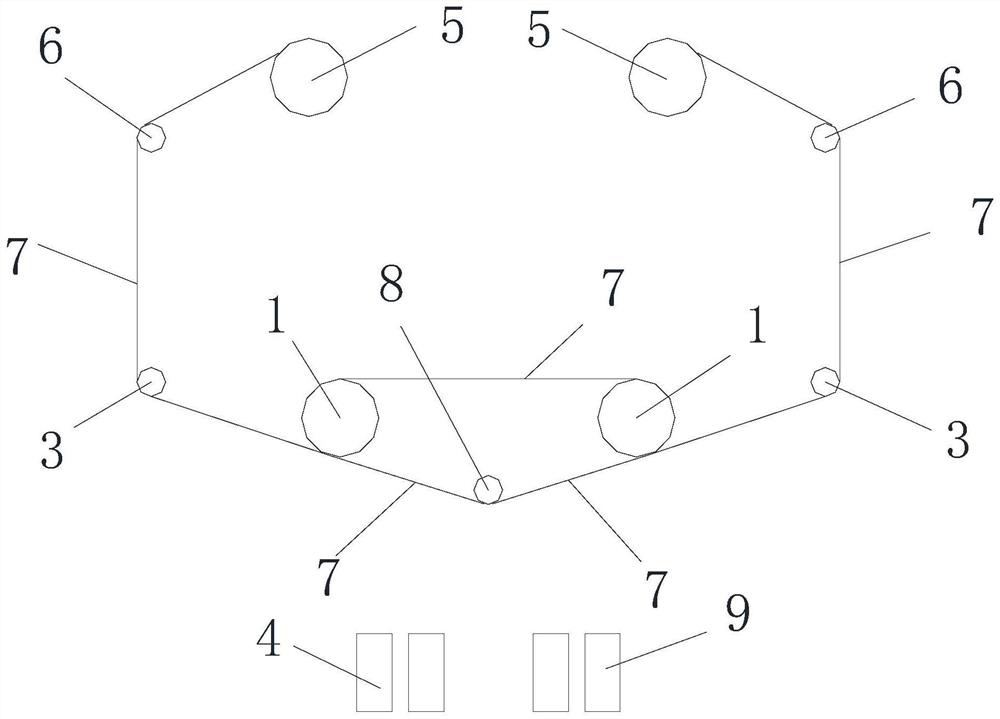

[0084] This embodiment provides a coating method for growing a second-generation high-temperature superconducting tape barrier layer composite film, which mainly includes the following steps:

[0085] Step 1: Put the base tape that has been electropolished into a vacuum chamber and wind it on the roller and drum several times;

[0086] The base belt is one of nickel-tungsten alloy, Hastelloy or stainless steel metal base belt; due to the use of the drum structure, the friction of the system is small, and the number of winding times is much higher than that of the water-cooled plate structure. In this implementation case, the winding is 25 times;

[0087] Step 2: Pull the vacuum to 1.0*E -5 Below Torr, feed the process gas and set the process pressure;

[0088] The process gas is argon and oxygen, the process pressure is controlled by a gate valve, and the pressure is 1-10mTorr;

[0089] In this implementation case, the process pressure is 4mTorr, and the process gas flow rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com