scroll compressor

A scroll compressor and scroll technology are applied in the field of scroll compressors to achieve the effects of reducing the rotating end plate, reducing the outer diameter and increasing the compression ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

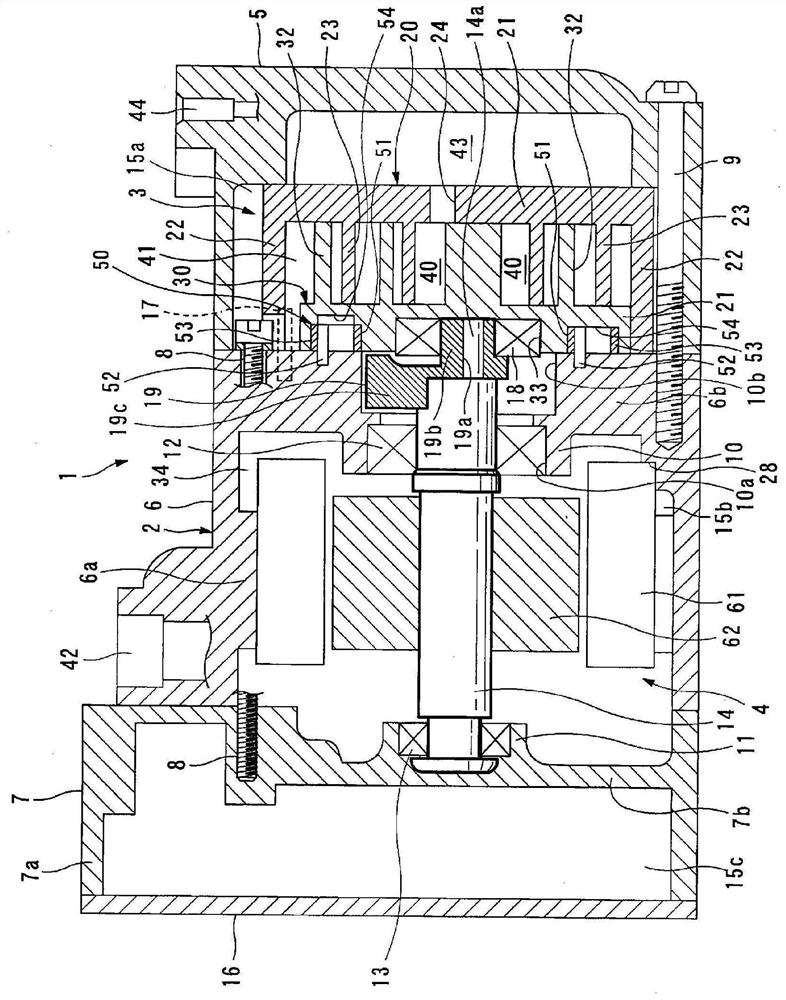

[0040] Below, while referring to the attached Figure 1 A configuration example of the scroll compressor of the present invention will be described.

[0041] exist figure 1 Among them, the scroll compressor 1 is an electric type compressor suitable for a refrigeration cycle using refrigerant as a working fluid, and a compression mechanism 3 is arranged on the right side of the figure in a housing 2 made of aluminum alloy. A motor 4 for driving the compression mechanism 3 is disposed on the left side in the figure. In addition, in figure 1 In the figure, let the left side in the figure be the front of the compressor 1, and let the right side in the figure be the rear of the compressor 1.

[0042] The casing 2 has a compression mechanism storage case member 5 that houses the compression mechanism 3 , a motor storage case member 6 that houses a motor 4 that drives the compression mechanism 3 , and houses an inverter device (not shown) that drives and controls the motor 4 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com