Novel backhoe loader

A two-headed, new type of technology, applied in earth movers/shovels, mechanically driven excavators/dredgers, construction, etc., can solve the problems of low construction efficiency and single function of construction machinery, and reduce the occupied space , Expand the scope of work, and enhance the effect of passability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

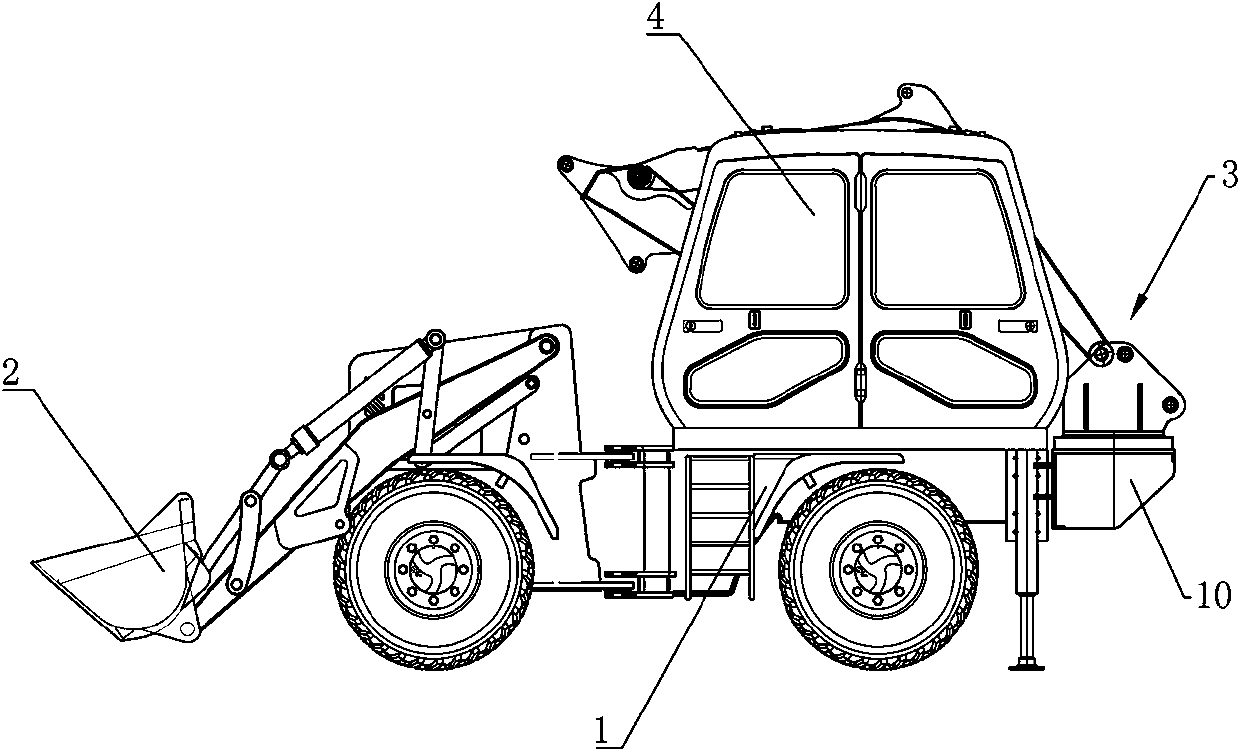

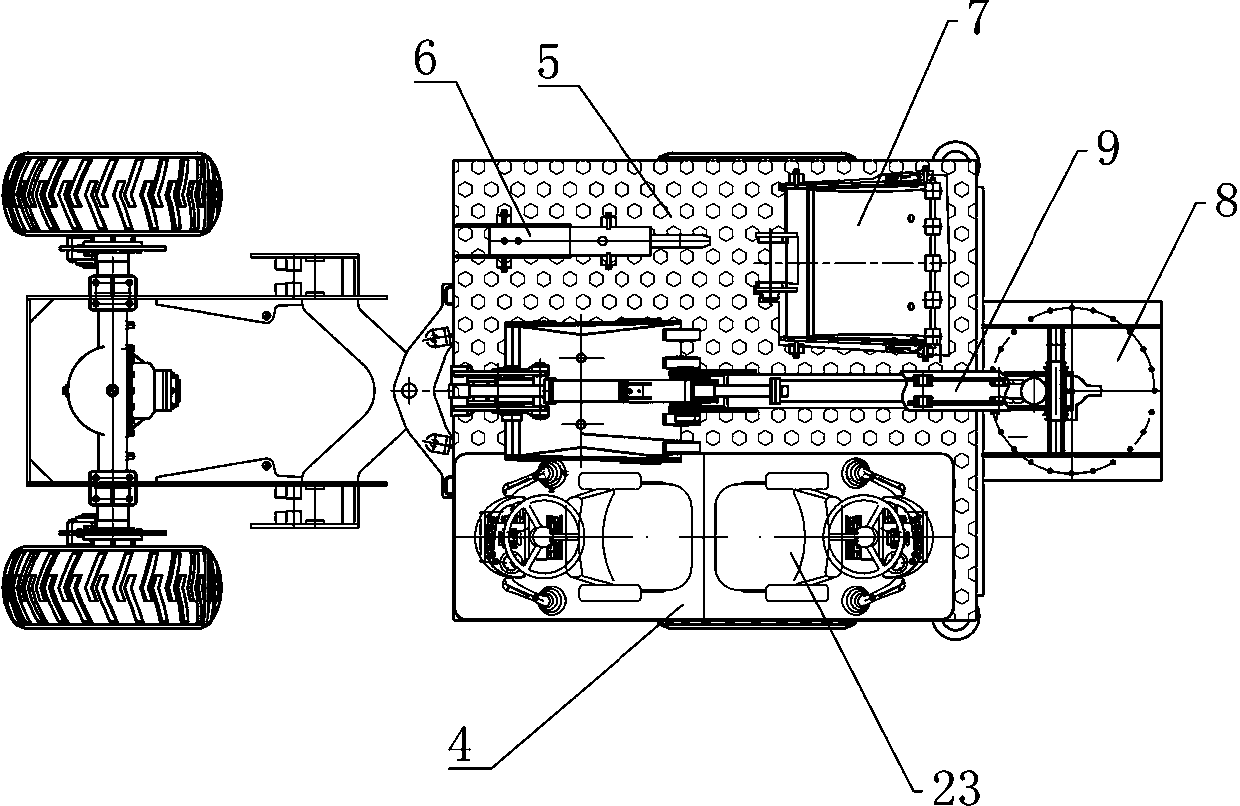

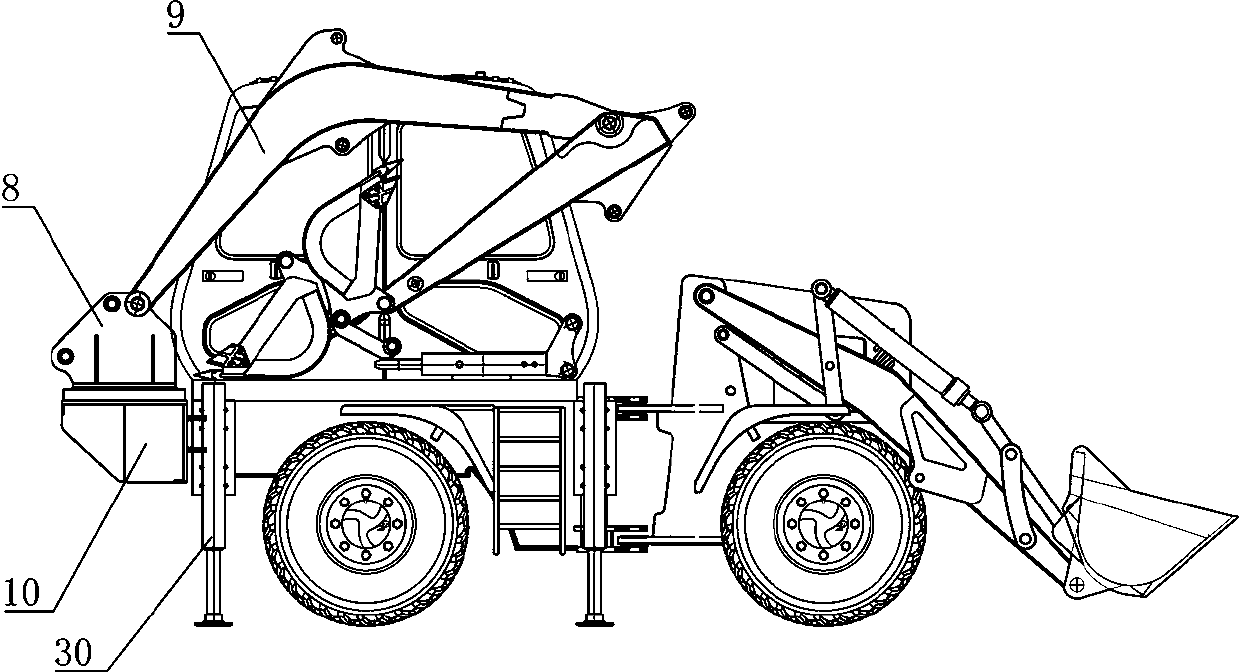

[0040] Such as Figure 1 to Figure 4 Commonly shown, it is a kind of embodiment that both ends of the present invention are busy, and it comprises movable car body 1, and the left end of car body 1 is provided with loading part 2, and right end is provided with digging part 3, and the center is driver's cab 4, and driving Two driving positions 23 are arranged front and back in the chamber 4, which can realize two-way driving, two-way operation, and one machine with two uses.

[0041] Will figure 1 The left end is defined as the front, and the right end is defined as the rear, then the loading part 2 is located on the center line of the front and rear directions of the car body 1, and the cab 4 is located on one side of the center line, so that the driver can easily Observing the operating conditions of the loading part 2 and the excavating part 3 has a good operating perspective. There is also a spare platform 5 for storing attachments on one side of the cab 4. The attachments...

Embodiment 2

[0049] Such as Figure 5 and Figure 6 As shown, it is a schematic diagram of Embodiment 2 of the present invention, and its difference from Embodiment 1 is that the backup platform 5 is changed to a self-discharging hopper 20, and one side of the self-discharging hopper 20 is hinged at the side of the car body 1, The bottom of the self-unloading hopper 20 is also provided with a jacking cylinder 21, and the jacking cylinder 21 can turn the self-unloading hopper 20 in a direction away from the cab 4.

[0050] The self-unloading hopper 20 of this embodiment can not only store attachments, but also load other materials, and has the function of transportation. After being transported to the destination, it can quickly and efficiently complete the self-unloading operation of materials, which has very good practicality. sex.

[0051] The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0053] Such as Figure 8 , Figure 9 and Figure 10 Commonly shown, it is a schematic diagram of Embodiment 3 of the present invention. The difference between it and Embodiment 1 is that this embodiment is also equipped with a hoisting part 11 on one side of the driver's cab 4, so that this embodiment has the functions of loading and digging at the same time. , hanging three functions, can complete three different operations, the hoisting part 11 includes the second rotating base 12 installed on the spare platform 5, the second rotating base 12 is fixed with the first main arm 13 extending upwards, the first The end of the main arm 13 is hingedly connected with the second auxiliary arm 14, and the end of the second auxiliary arm 14 is hingedly connected with the third auxiliary arm 15, between the first main arm 13 and the second auxiliary arm 14, between the second auxiliary arm 14 and The third auxiliary arms 15 are connected with hoisting oil cylinders 16, and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com