Ink ribbon cartridge

A technology for ink ribbon cassettes and ink ribbons, applied in the directions of ink ribbon cassettes, inking devices, printing, etc., can solve the problems of unreliable image printing media, etc., and achieve the effect of preventing contact and increasing the number of windings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

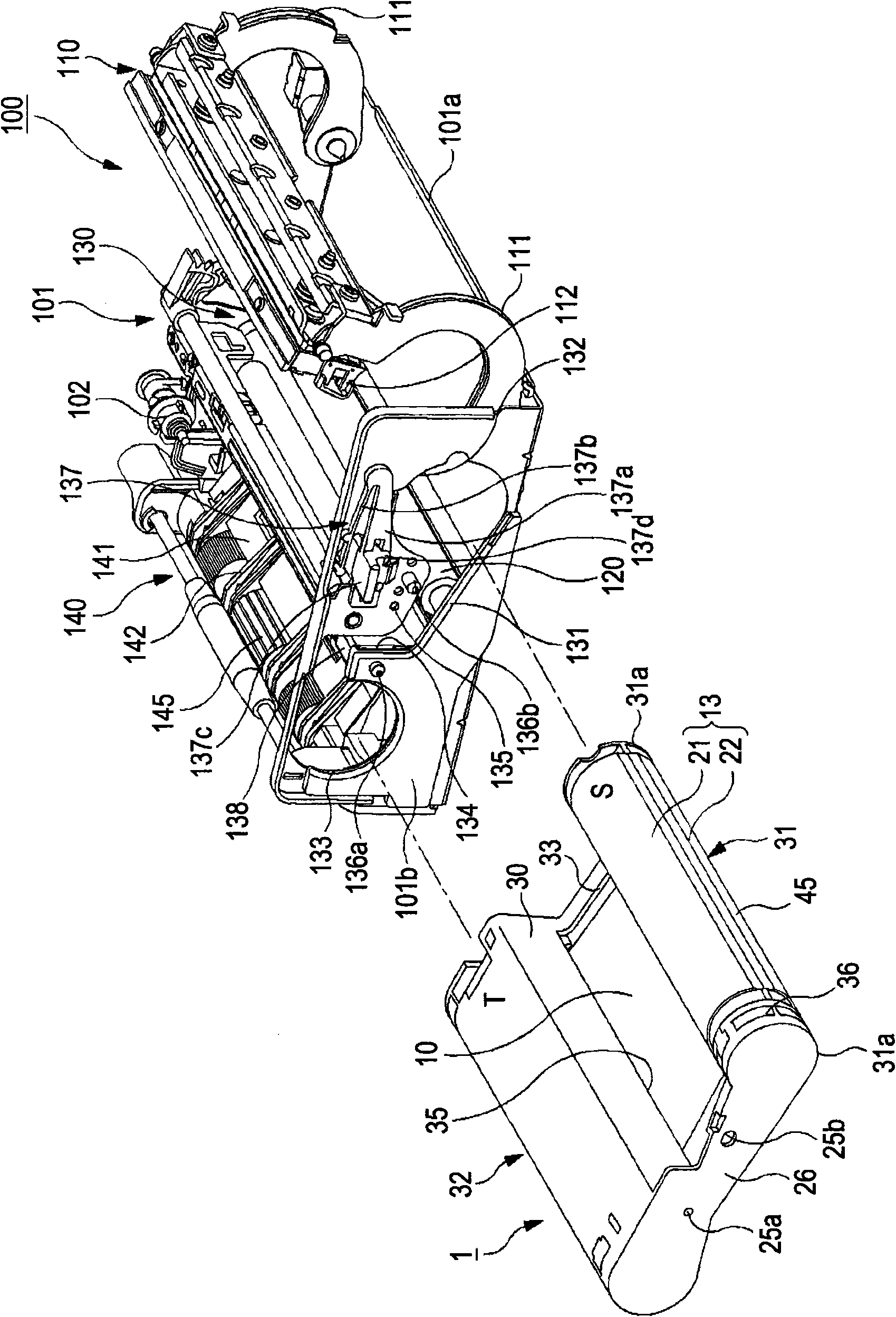

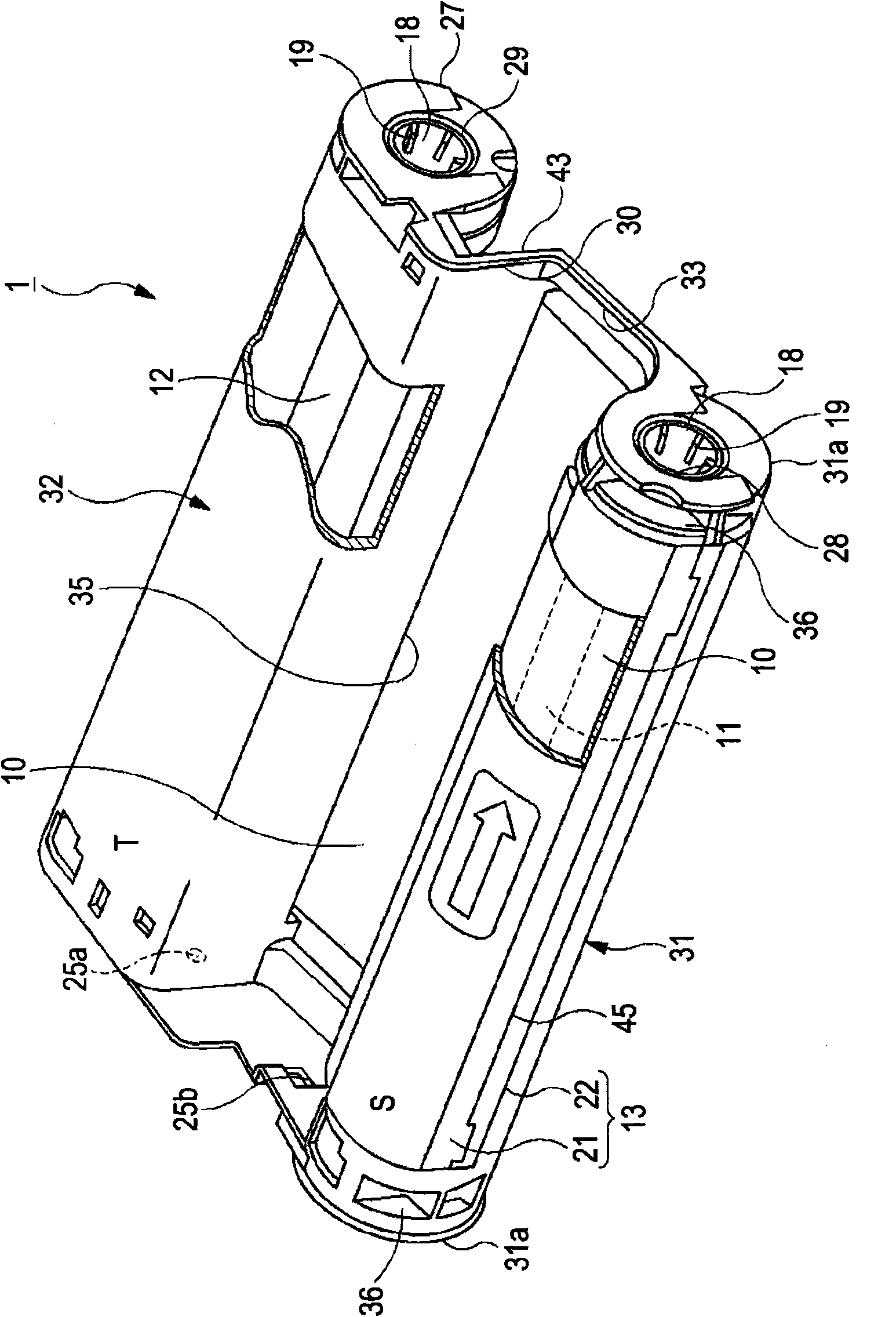

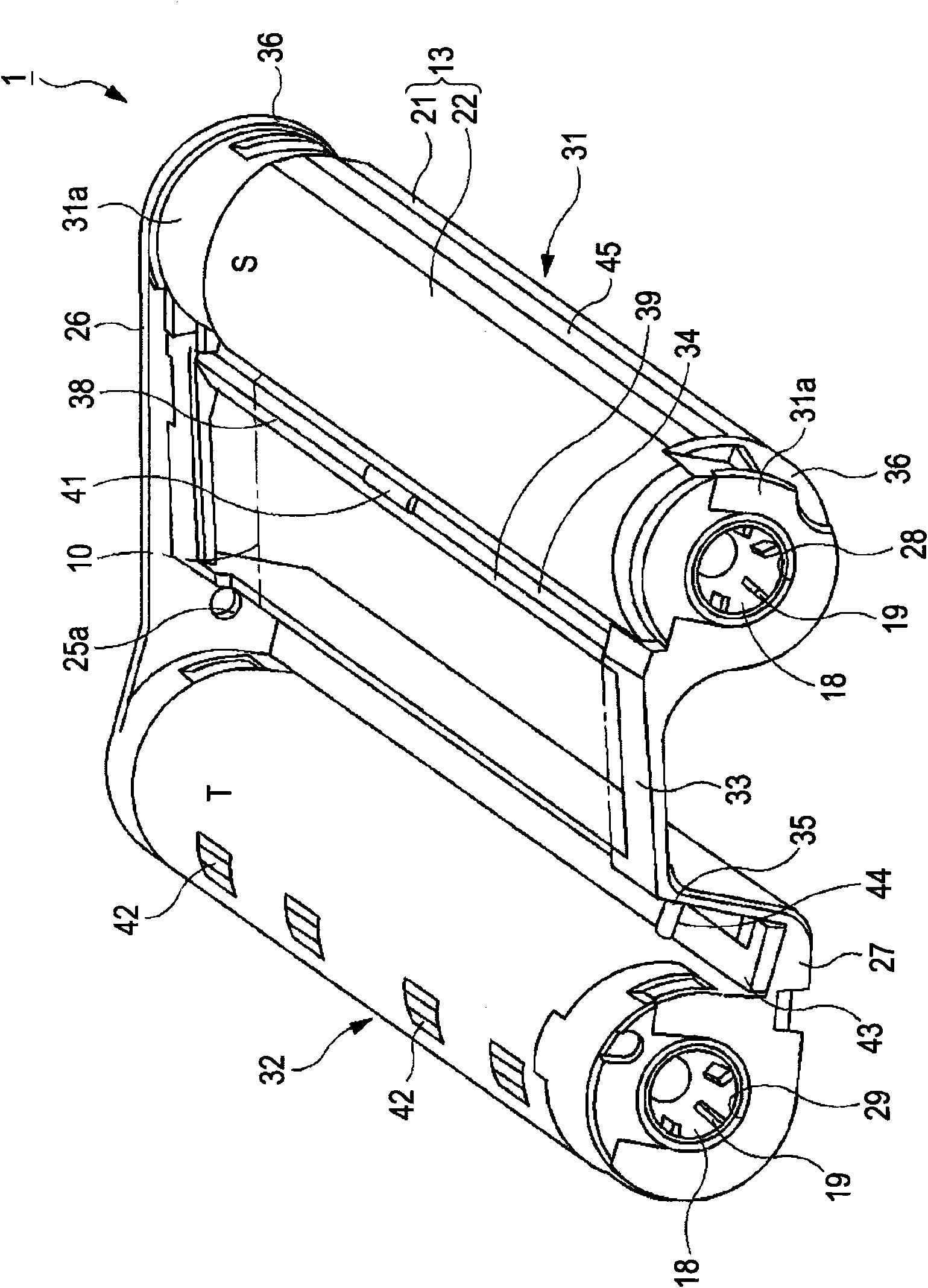

[0034] An ink ribbon cartridge according to an embodiment of the present invention will be described in the following order with reference to the drawings.

[0035] 1. General description

[0036] 2. Description of ink ribbon box

[0037] 2-1. Ink Ribbon Description

[0038] 2-2. Description of the scroll

[0039] 2-3. Description of the box body

[0040] 2-4. Explanation of supply side belt housing

[0041] 2-5. Explanation of belt guide

[0042] 2-6. Description of concave guide

[0043] 2-7. Explanation of the take-up side belt housing

[0044] 2-8. Explanation of supply side flat part and winding side flat part

[0045] 3. Description of thermal transfer printer unit

[0046] 3-1. Explanation of box installation part

[0047] 3-2. Description of thermal head and drum

[0048] 3-3. Description of the transport mechanism of the image printing medium 150

[0049] 4. Operating Instructions

[0050] 5. Effect description

[0051] 5-1. Effect 1

[0052] 5-2. Effect 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com