Restraint ring support device

A technology of support device and restraint ring, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and thin material handling, etc., can solve the problem of unequal design structure, achieve the effect of flexible use, reasonable structure design, and ensure product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

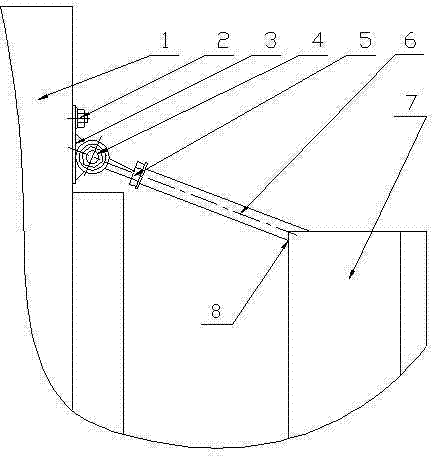

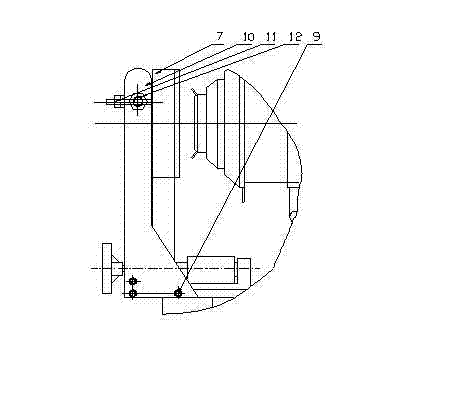

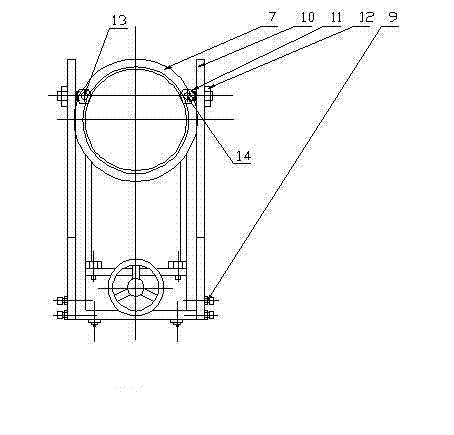

[0018] The present invention as figure 1 , figure 2 , image 3 shown. A confinement ring support device, at least one set is provided, including a first support device and a second support device. The first supporting device is a movable and adjustable rod-shaped structure, mainly composed of a first adjusting bolt, a first lock nut, and a supporting rod, and is arranged between the restraining ring of the front winding device and the reduction box. The support rod is an empty sleeve structure provided with an internal thread, and is movably connected with the thread of the first adjusting bolt. The first locking nut is placed between the first adjusting bolt and the support rod. One end of the first supporting device is fixedly connected to the upper end of the reduction box by the first fixing bolt 2 through the first fixing bracket, and the other end of the first supporting device is in contact with the first fulcrum 8 having an annular groove structure at the axial up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com