A heat shrink wrapping tape cutting device

A cutting device and winding tape technology, which is applied in metal processing and other directions, can solve the problems that heat shrinkable winding tape cannot be adapted to the application, time-consuming manual cutting, and width errors, etc., and achieve the effect of simple structure, low cost, and improved cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

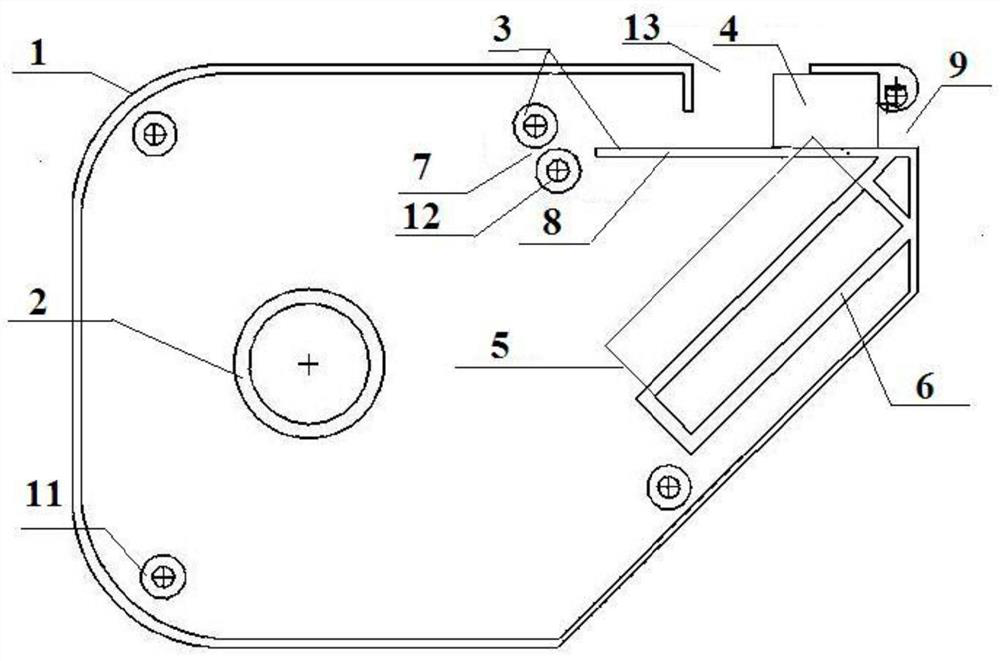

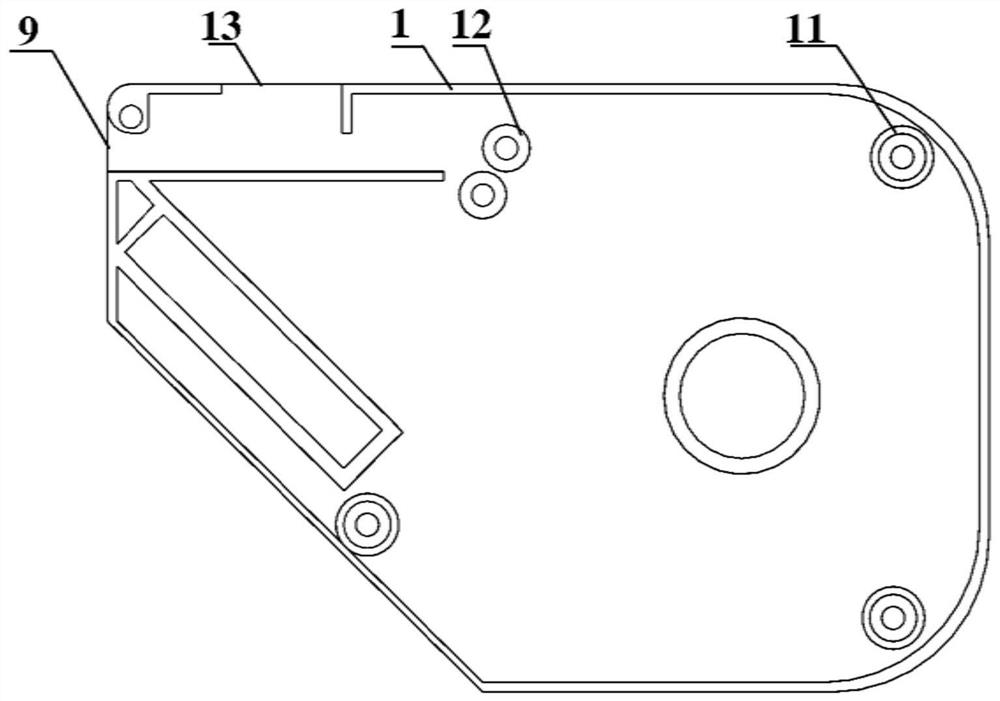

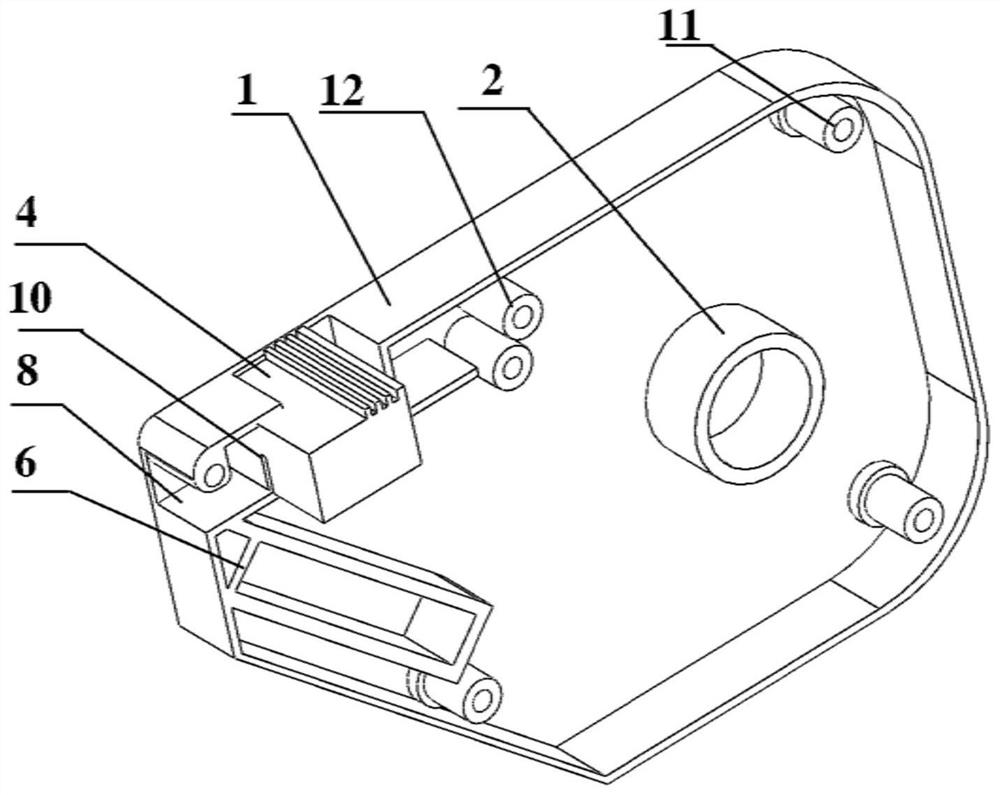

[0035] Such as Figure 1 ~ Figure 4 As shown, a heat-shrinkable winding tape cutting device includes a housing 1, the housing 1 is detachable, and the inner wall of the housing 1 is provided with a fixing part 2, a supporting part 3, a pressing part 4 and a blade 5; 2. It is used to fix the whole roll of heat-shrinkable wrapping tape. The support part 3 is used to support the output of the heat-shrinkable wrapping tape. The support part 3 includes a support shaft 7 and a support plate 8. The support plate 8 is connected to the tape outlet 9. The pressing part 4 is set relative to the support plate 8 and is used to compress the heat-shrinkable wrapping tape located on the support plate 8, the blade 5 is installed on the pressing part 4 and the extending direction of the blade 5 is consistent with the strip-out direction of the heat-shrinkable wrapping tape , and contact with the heat shrinkable wrapping tape on the support plate 8 when the pressing part 4 presses the heat shrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com