Heat-shrinkable wrapping tape cutting device

A cutting device and winding tape technology, which is applied in metal processing and other directions, can solve the problems that heat-shrinkable winding tape cannot be adapted to the application, time-consuming manual cutting, and width errors, etc., and achieve the effect of simple structure, low cost, and improved cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

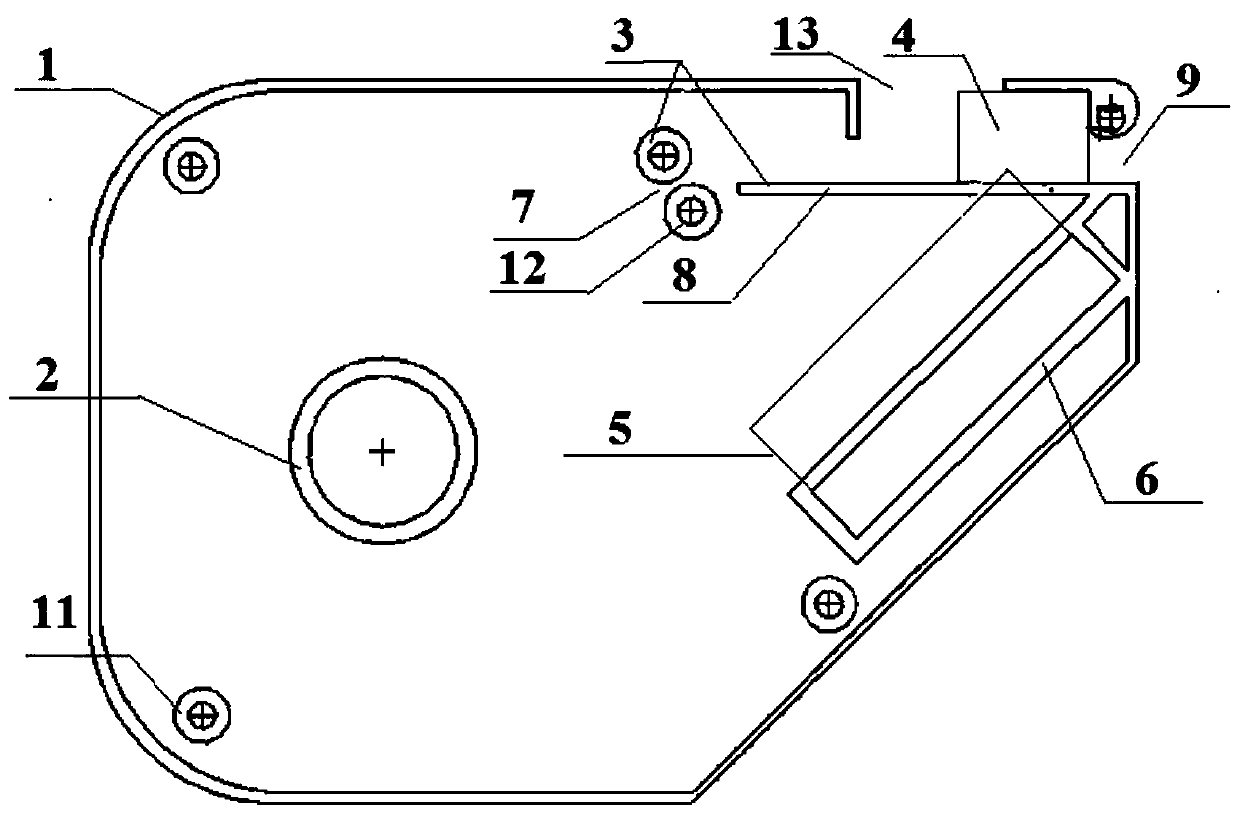

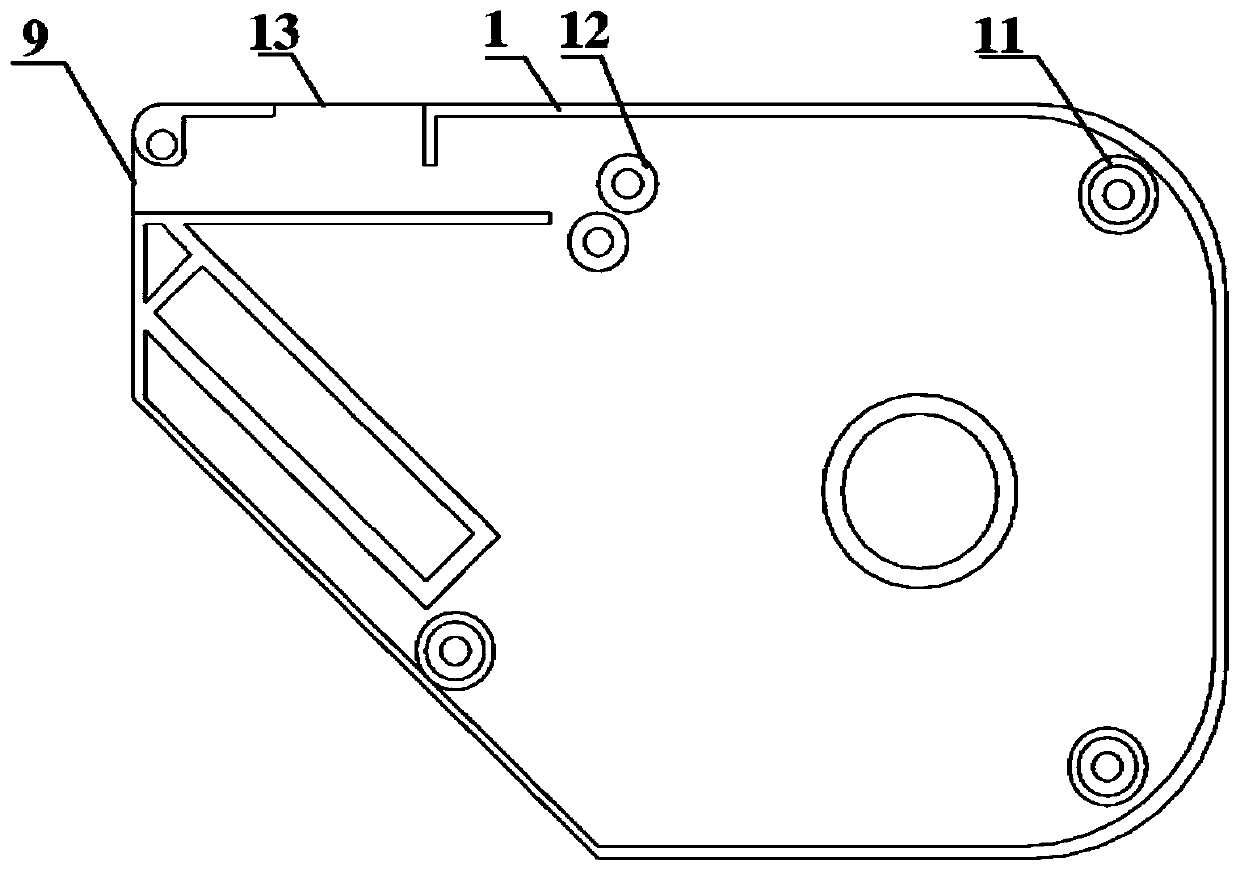

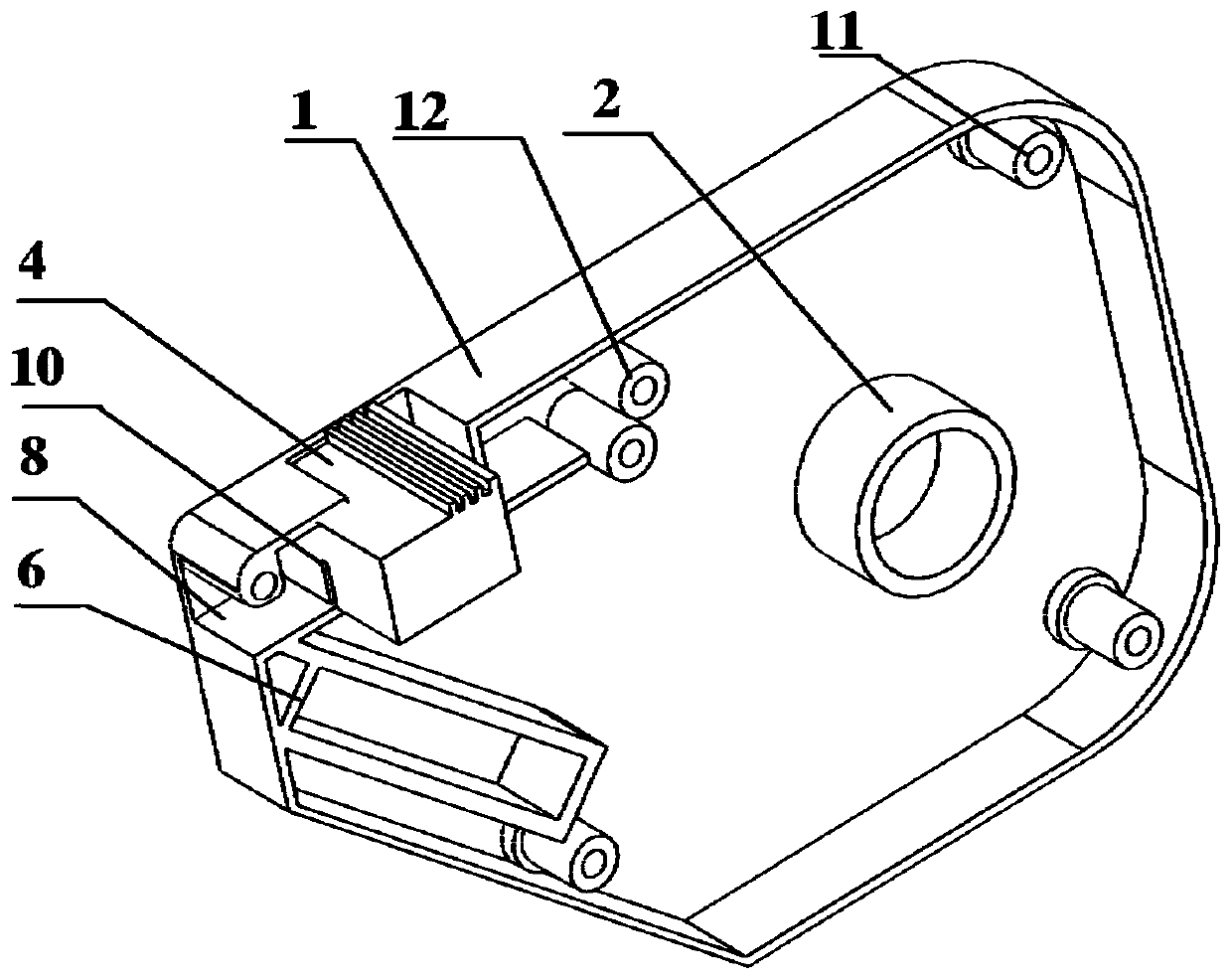

[0035] Such as Figure 1 to Figure 4 As shown, a heat-shrinkable winding tape cutting device includes a housing 1, the housing 1 is detachable, and the inner wall of the housing 1 is provided with a fixing part 2, a supporting part 3, a pressing part 4 and a blade 5; 2. It is used to fix the whole roll of heat-shrinkable wrapping tape. The support part 3 is used to support the output of the heat-shrinkable wrapping tape. The support part 3 includes a support shaft 7 and a support plate 8. The support plate 8 is connected to the tape outlet 9. The pressing part 4 is set relative to the support plate 8 and is used to compress the heat-shrinkable wrapping tape located on the support plate 8, the blade 5 is installed on the pressing part 4 and the extending direction of the blade 5 is consistent with the strip-out direction of the heat-shrinkable wrapping tape , and contact with the heat-shrinkable wrapping tape on the support plate 8 when the pressing part 4 presses the heat-shri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com