Prestressed inclined pile support and construction method thereof

A construction method and prestressing technology, which is applied in excavation, infrastructure engineering, construction, etc., can solve problems such as difficult recovery of loading devices, influence on underground main structure construction, foundation pit deformation and unfavorable protection of surrounding environment, etc., to achieve a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

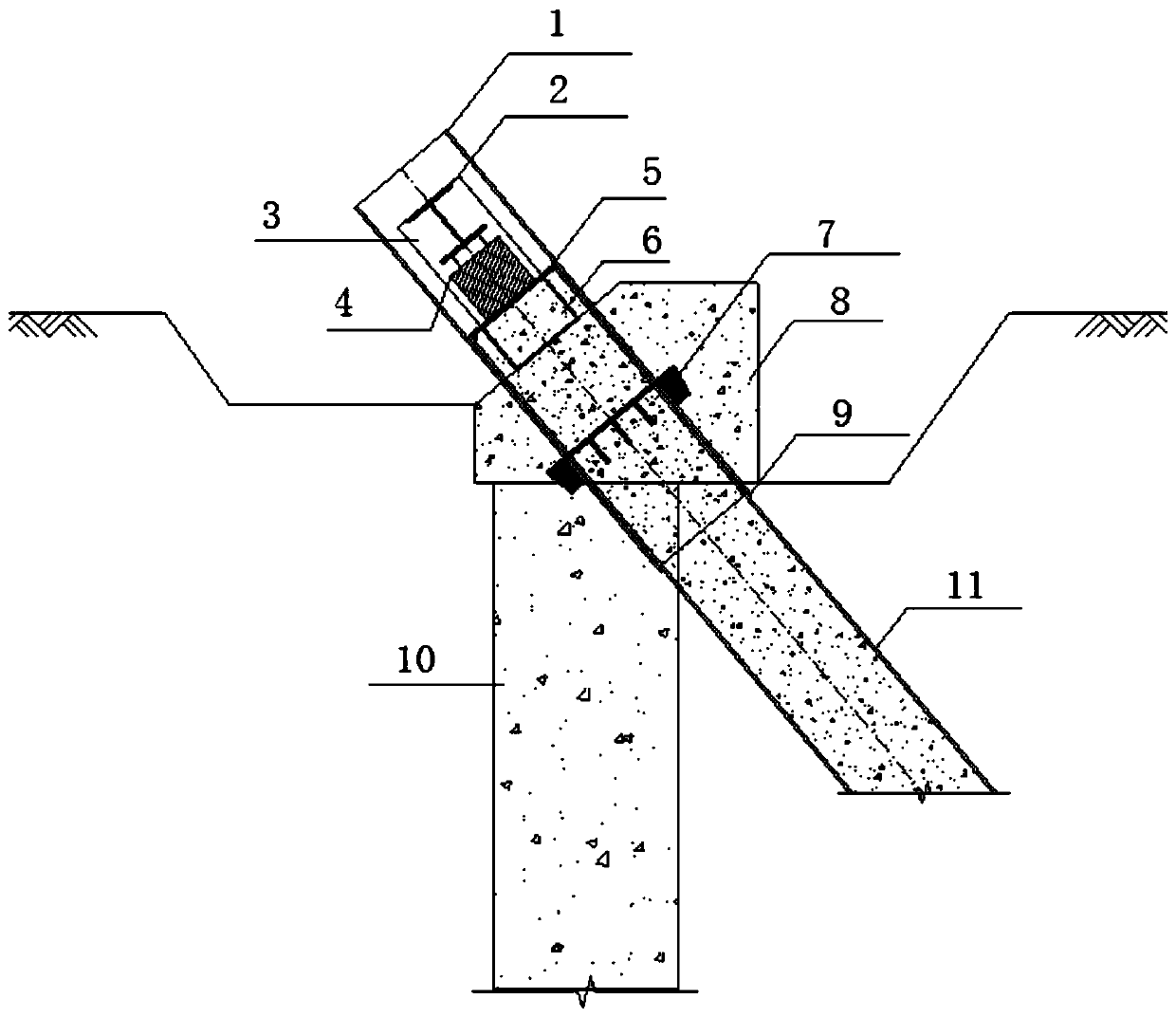

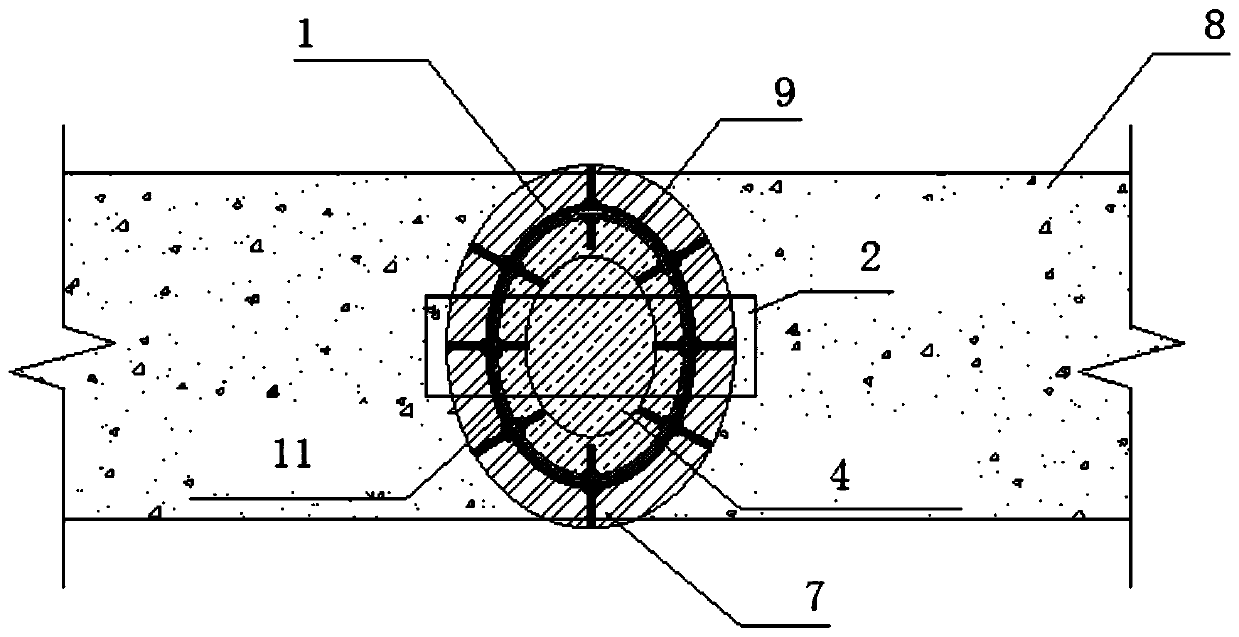

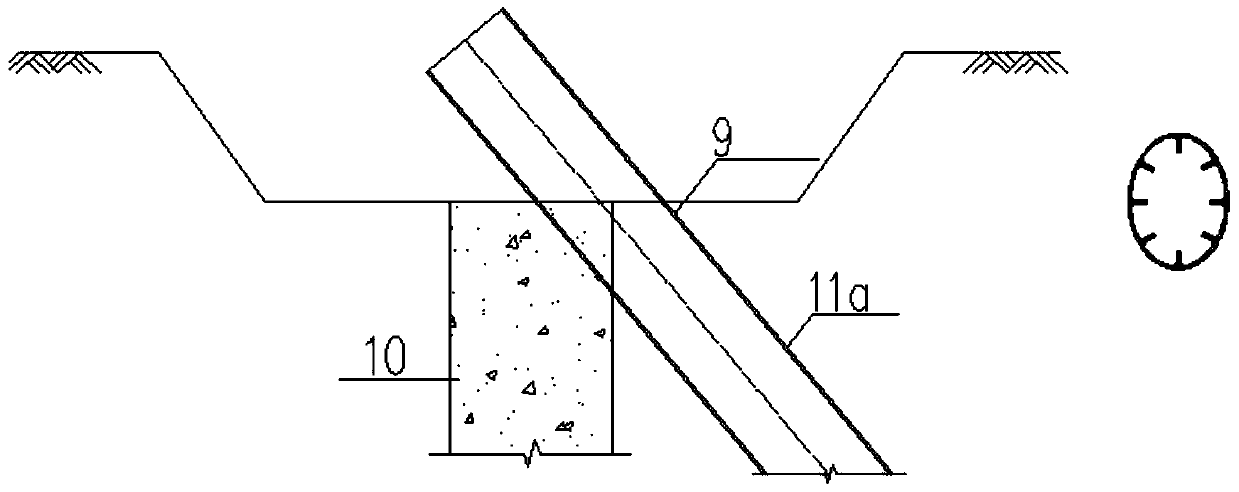

[0050] see Figure 1-Figure 2 , a prestressed inclined pile support, comprising an inclined pile support 11, a purlin 8, a pullout device 1, and a loading device 4; the inclined pile support 11 is driven into the soil before excavation; 8 for support; the anti-pull device 1 is flexibly connected with the inclined pile support 11 in the axial direction; It is fixed in the purlin 8, and the loading device 4 is installed on the part where the upper end protrudes from the purlin 8. It should be noted that the prestressing device for inclined piles is located outside the ring beam, which has a wide application range and can extend to the ground to avoid the impact of groundwater due to the ring beam falling to the bottom.

[0051] As a preferred embodiment, the anti-pull device 1 is a steel pipe sleeved on the inclined pile support 11, the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com