End embedded type prestressed inclined pile and construction method thereof

A construction method and prestressing technology, applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve problems such as difficult recovery of loading devices, deformation of foundation pits, and unfavorable and impactful protection of the surrounding environment, achieving the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

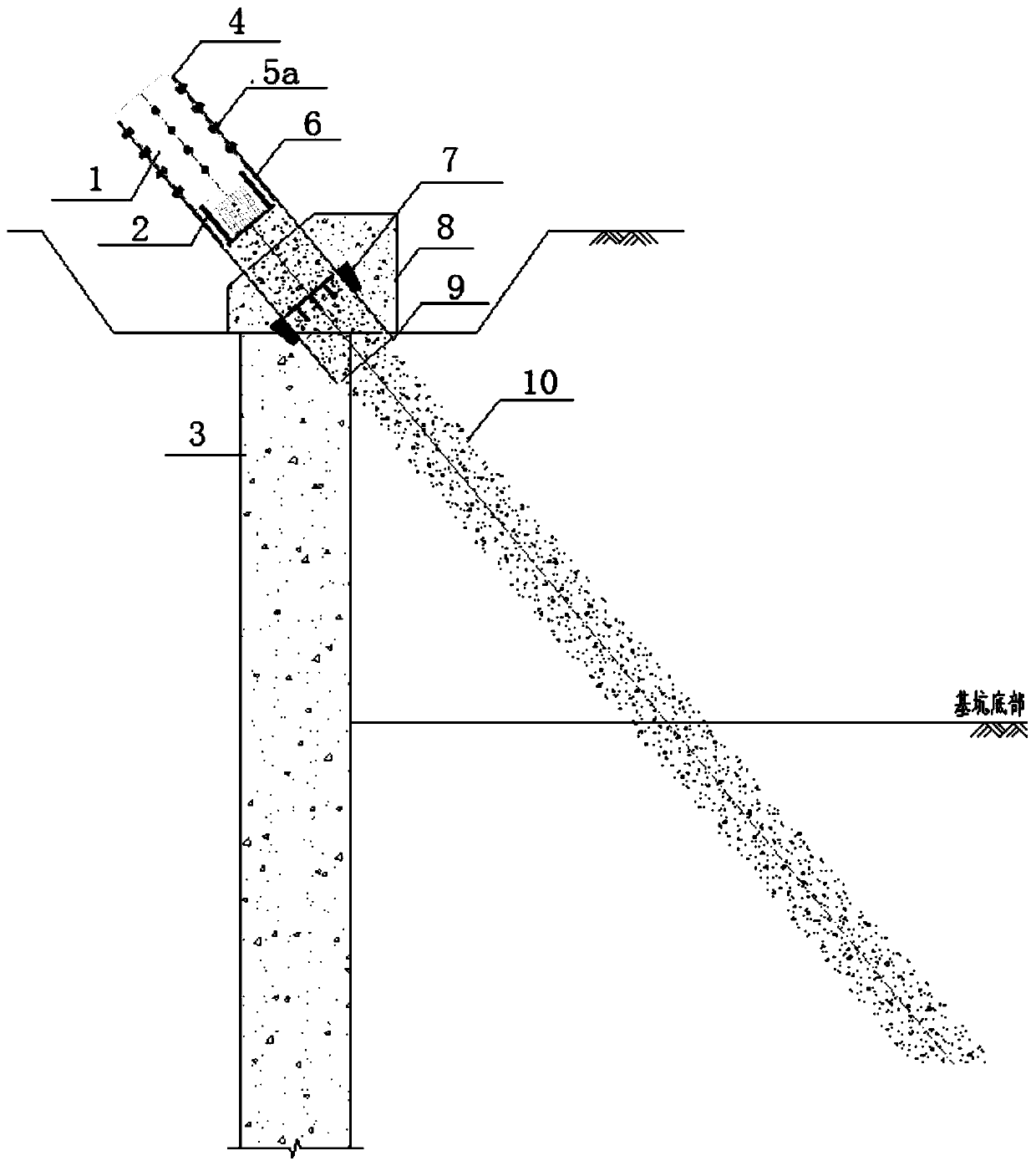

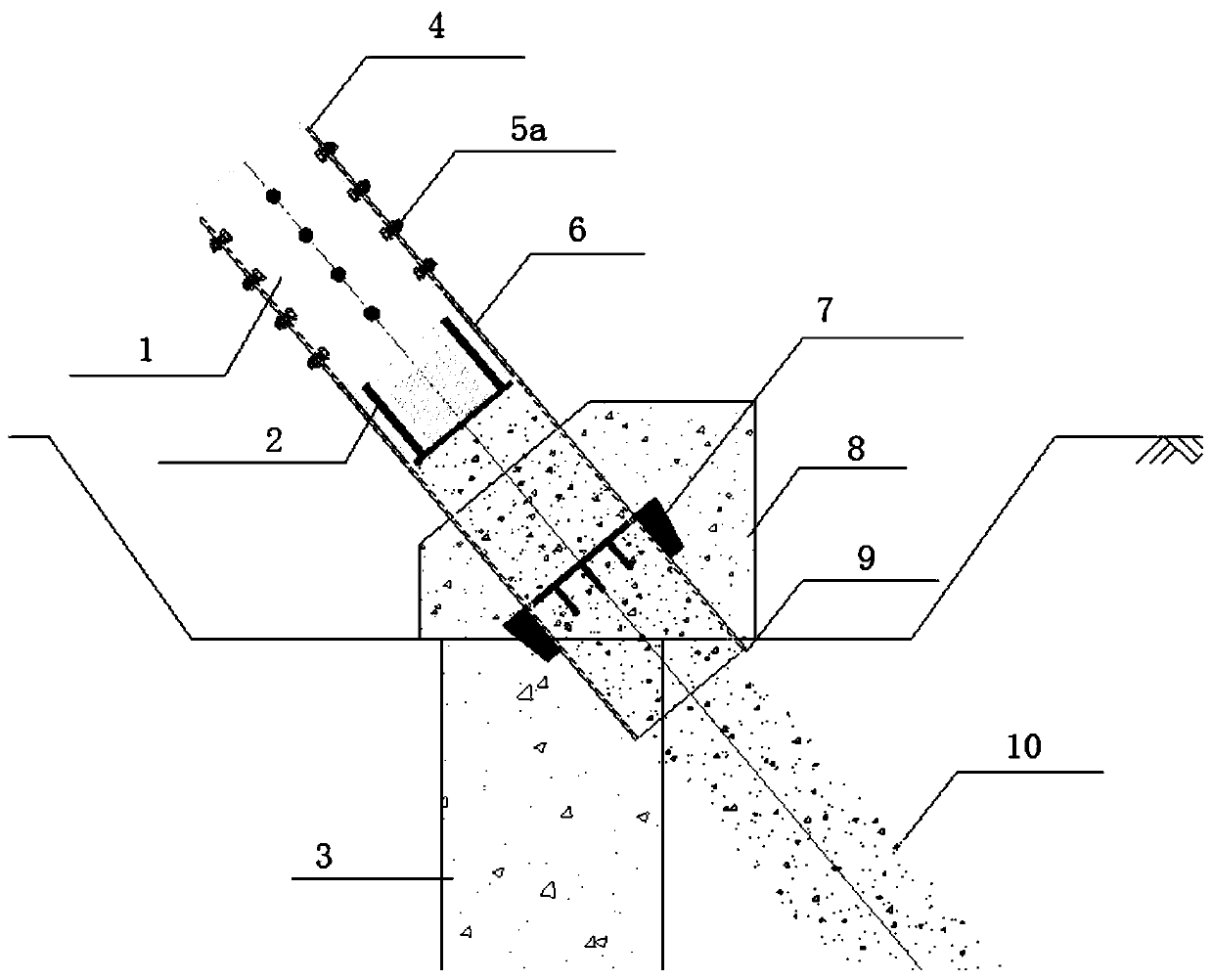

[0052] see Figure 1-Figure 2 , an end-embedded prestressed oblique pile, comprising an oblique pile, a purlin, an anti-pull device, and a loading device; the oblique pile is driven into the soil before excavation; Flexible connection; the loading device takes the pullout device as the force point, and applies axial prestress to the inclined pile; the pullout device is pre-embedded and fixed in the purlin, and the part where the upper end protrudes from the purlin is installed with the loading device; the pullout device and the The loading device is locked and fixed by a detachable positioning device.

[0053] In this embodiment, the anti-pull device 4 is in the shape of a cylinder, and is sleeved on the outside of the inclined pile 10, and the loading device 1 is arranged inside the anti-pull device 4; Multiple corresponding positioning holes, the two are fastened and positioned by multiple bolts, such as figure 1 and figure 2 shown.

[0054] In this embodiment, the upper ...

Embodiment 2

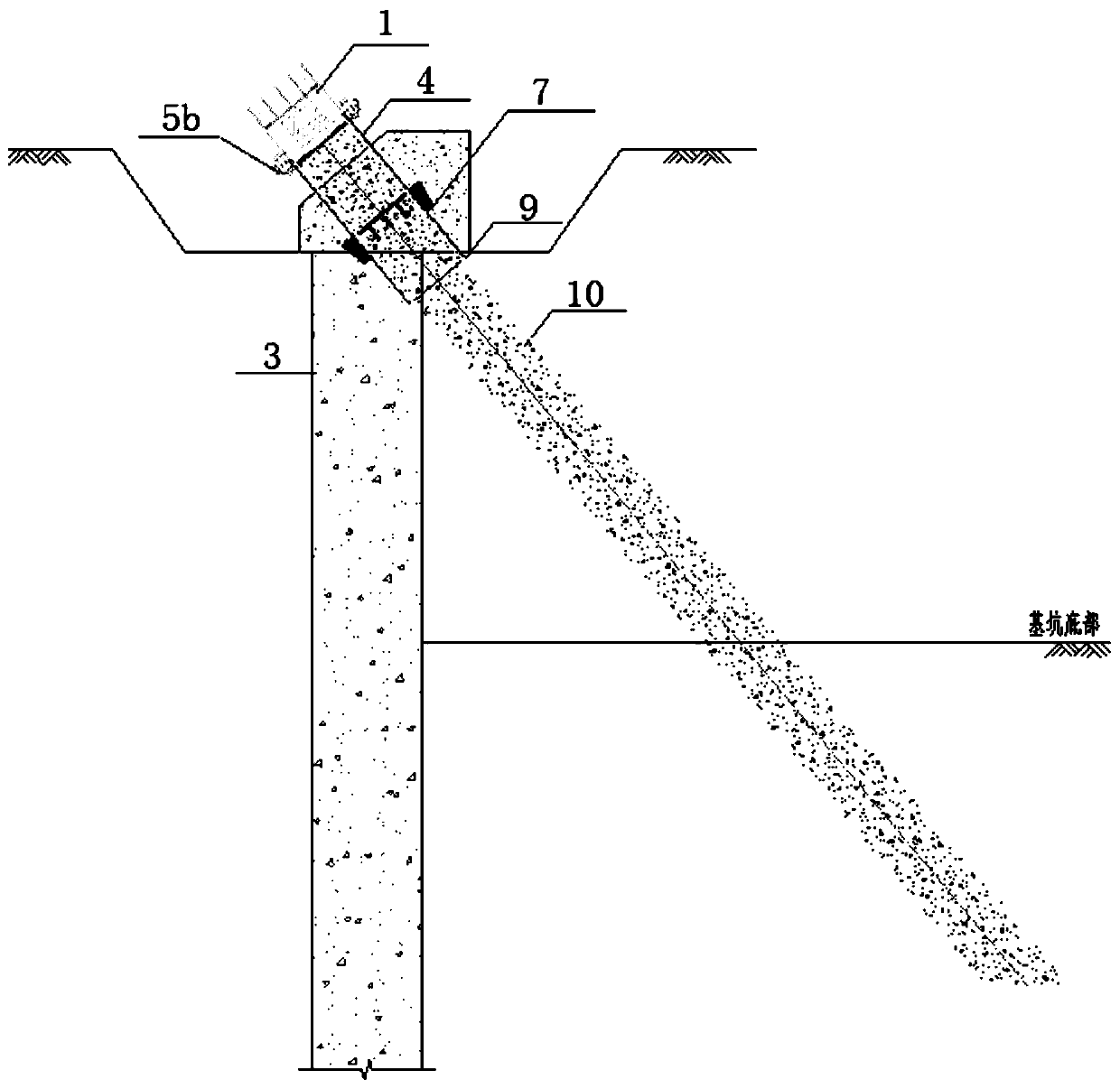

[0071] see Figure 3-Figure 4 The difference between this embodiment and Embodiment 1 is that the positioning device 5b is different from Embodiment 1. The positioning device adopts a flange, and the loading device 1 is fixedly connected to the upper end of the pullout device 4 through the flange. It is fixed with the anti-pull device, which can also provide a force point for the loading device.

[0072] The construction method in this embodiment, as Figure 13-Figure 18b shown, including the following steps:

[0073] S1. Construction enclosure piles, inclined piles; Figure 13-14 shown;

[0074] S2. After the processing of the connection device (loading port, lateral anti-slip device) is inserted into the inclined pile, the bottom end of the connection device is fixed to the limit point; Figure 15 shown;

[0075] S3. Construction ring beams, such as Figure 16a , 16b shown;

[0076] S4. After the maintenance meets the design requirements, install the loading device; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com