End type prestress batter pile and construction method thereof

A construction method and prestressing technology, applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve problems such as difficult recovery of loading devices, influence on underground main structure construction, and unfavorable protection of surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

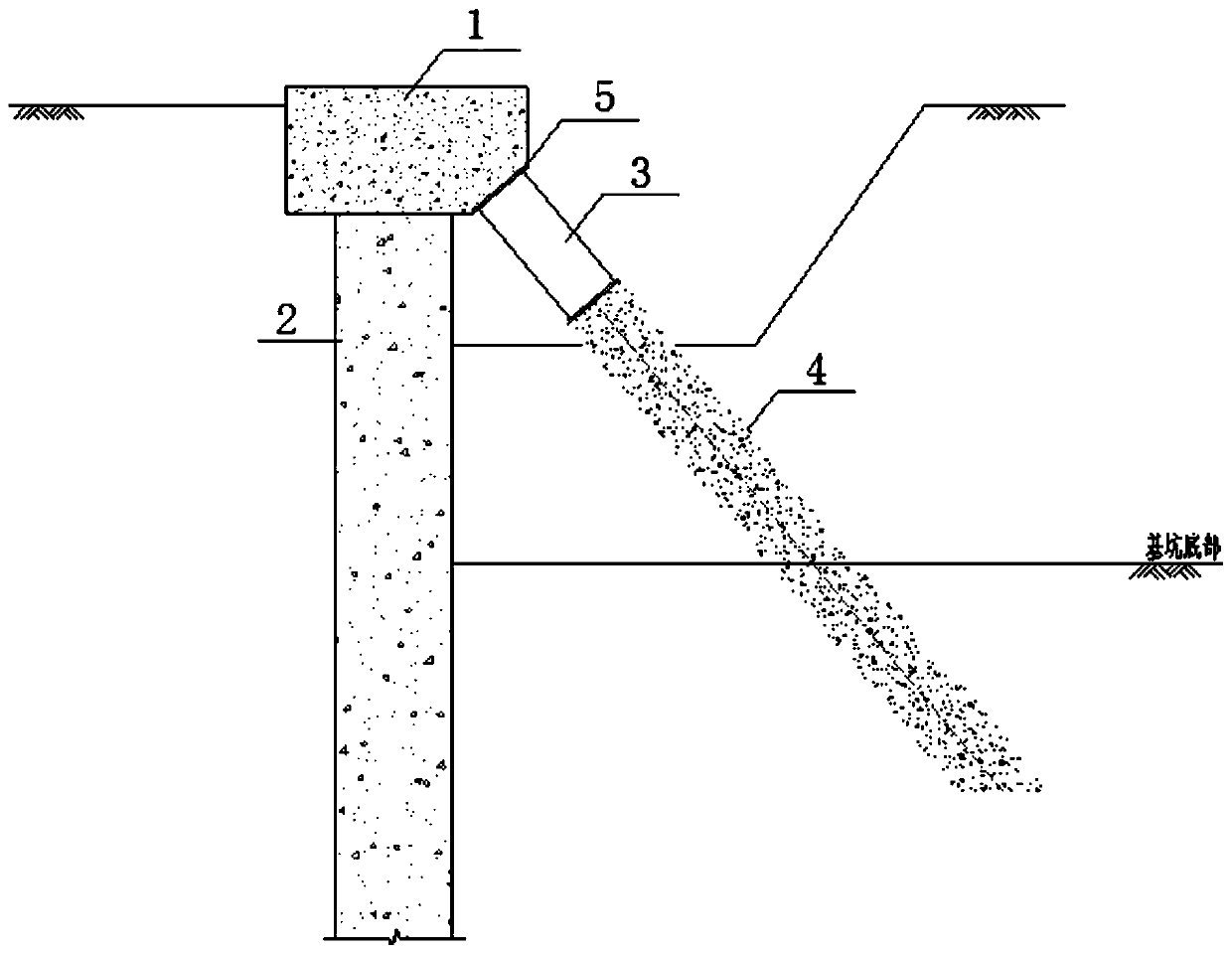

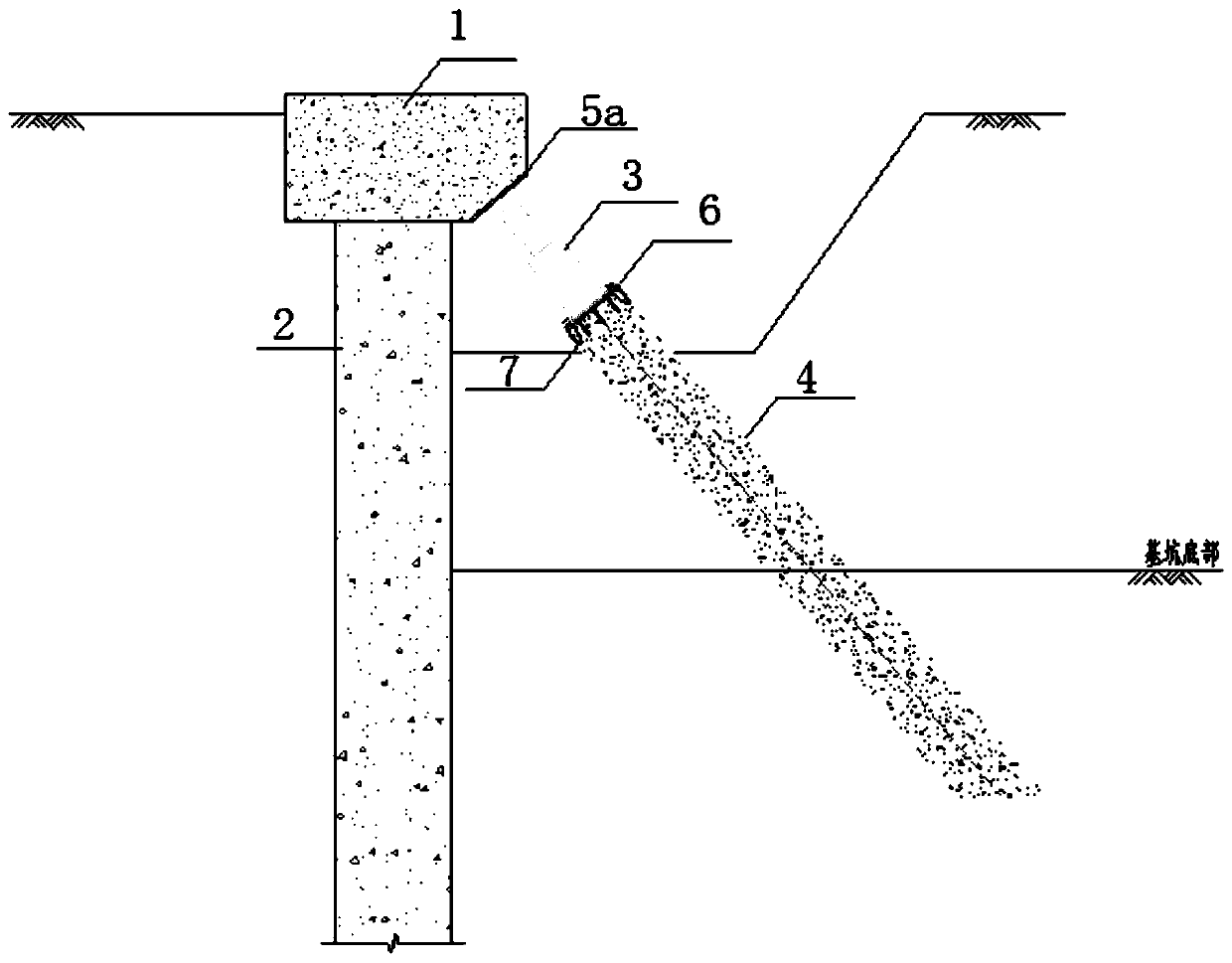

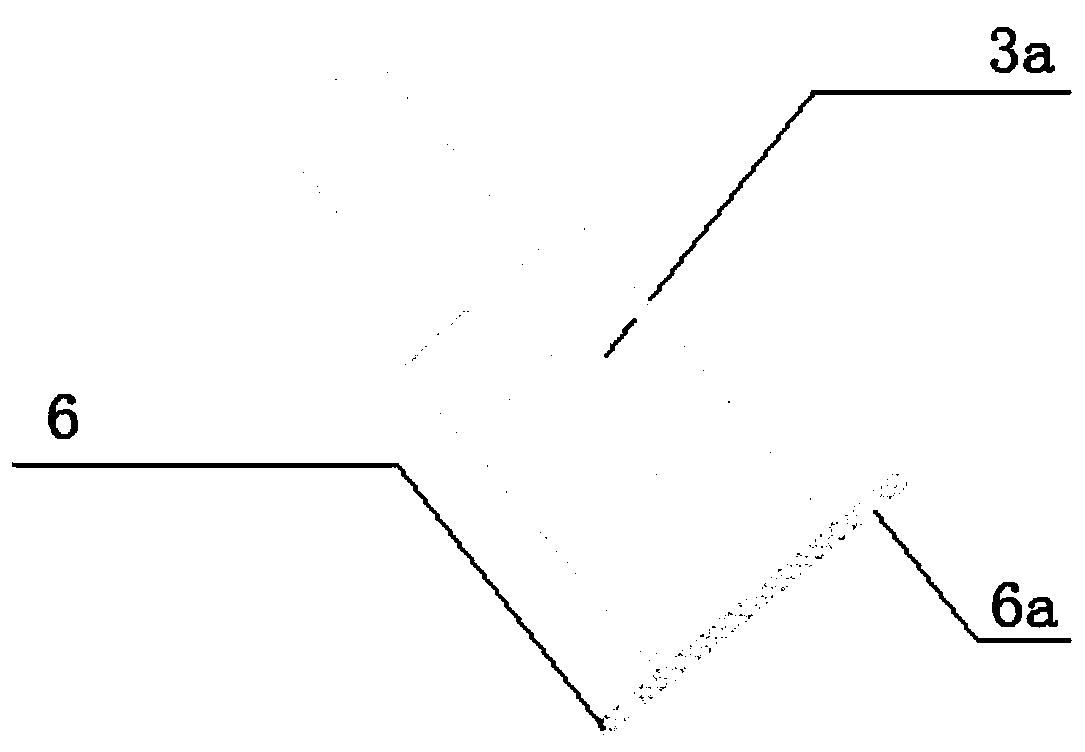

[0035] see Figure 1-Figure 9 , an end-type prestressed inclined pile, comprising a surrounding purlin 1, a surrounding pile 2, a diagonal pile 4, and a loading device 3; the surrounding purlin 1 is supported by the surrounding pile 2; Drive into the soil, a set spacing is reserved between the top of the inclined pile 4 and the purlin 1, and the loading device 3 is set within the set spacing, and the loading device 3 is inclined by the reaction force provided by the purlin 1. The piles 4 are prestressed.

[0036] In this embodiment, the inclined piles 4 are one or more of elongated axially stressed rods such as steel pipes, profiled steels, composite steels, prefabricated pipe piles, square piles, and steel and concrete combined.

[0037] In this example, see Figure 1-2 , the lower end of the inclined pile 4 is embedded in the bottom soil of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com