Applicator comprising an integrated control circuit

A technology for controlling circuits and applicators, applied in the directions of circuits, electromagnets, electrical components, etc., to achieve the effect of not easy to interrupt, reduce current, and reduce the number of wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

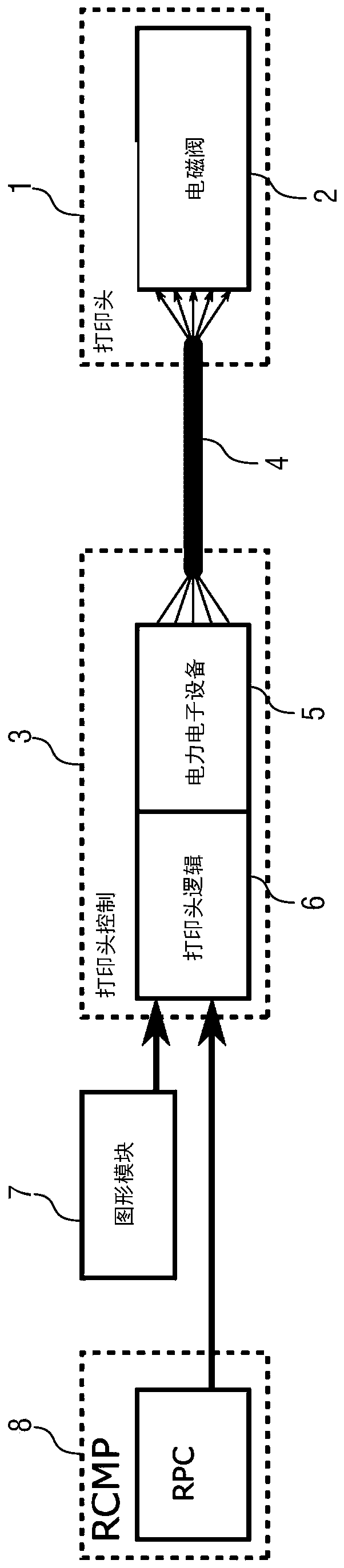

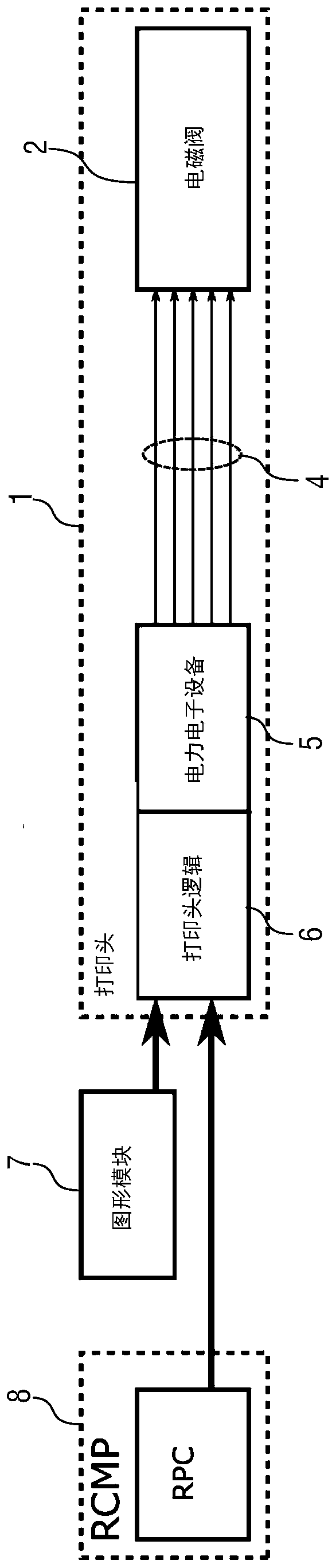

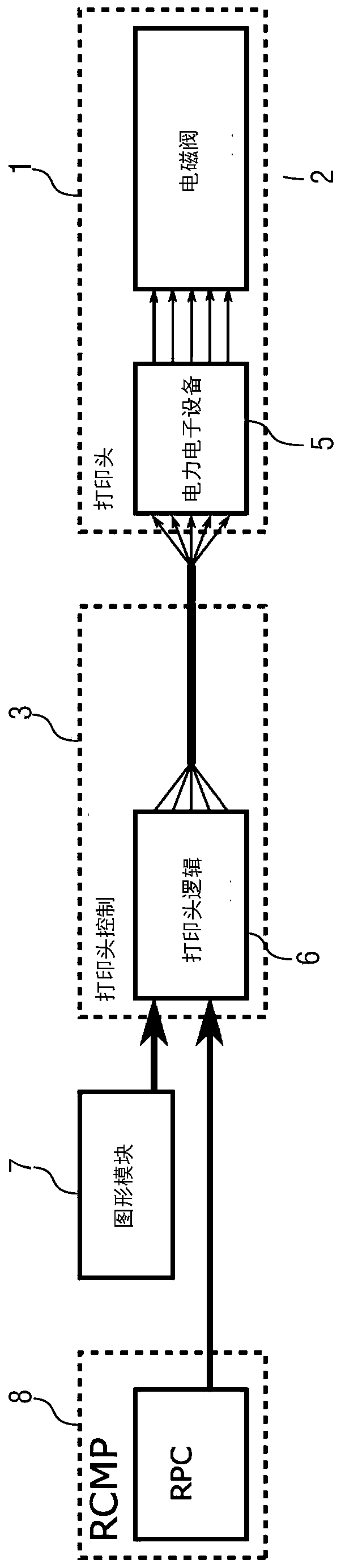

[0079] figure 2 A schematic diagram of a painting device based on the present invention is shown. For example, the painting device can be used to paint a car body component. This embodiment according to the present invention partially corresponds to the expression described above and shown in FIG. 1, so to avoid repetition, reference is made to the above description, whereby the same reference numerals are used for corresponding details.

[0080] A special feature of this embodiment is that the print head logic 6 and the power electronics 5 are integrated in the print head 1.

[0081] On the one hand, this has the following advantages: the line 4 between the power electronic device 5 and the solenoid valve 2 is less likely to be interrupted.

[0082] On the other hand, the line between the power electronic equipment 5 and the solenoid valve 2 is also less sensitive to interference EMC emissions from the outside.

[0083] Another advantage is that the line between the power electronic ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap