A stamping die equipment

A stamping die and equipment technology, applied in the field of stamping dies, can solve the problems of reducing the utilization rate of steel strips or strips, unfavorable stamping of steel strips or strips, wasting strips or steel strips, etc., achieving simple structure and improving utilization rate , Improve the effect of stamping quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

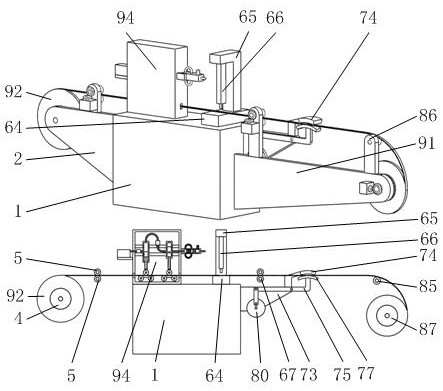

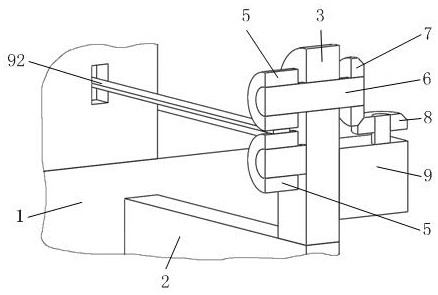

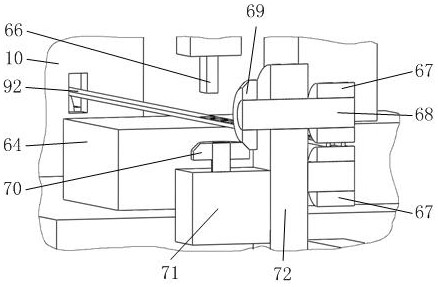

[0037] Such as figure 1 As shown, it includes a base 1, a winding roller A4, a flattening mechanism 94, a stamping platform 64, a support arm 65, a punch 66, a winding roller B87, and an electric drive module D90. figure 1 , 5 As shown, a tape 92 is wound on the winding roller A4 installed on one side of the base 1; a flattening mechanism 94 for flattening the tape 92 with a radian is installed on the base 1; a stamping platform 64 is installed on the base 1, and the stamping Support arm 65 is installed on the platform 64, and punch 66 is installed on the support arm 65; The punch 66 cooperates with the stamping platform 64, to stamp the strip 92 that is extruded straight by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com