Anti-deformation stamping equipment for sheet metal part machining

A technology of stamping equipment and sheet metal parts, which is applied in the field of anti-deformation stamping equipment for sheet metal processing, which can solve the problems of different thickness and easy deformation of sheet metal parts, and achieve the effect of preventing abnormal movement and facilitating removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

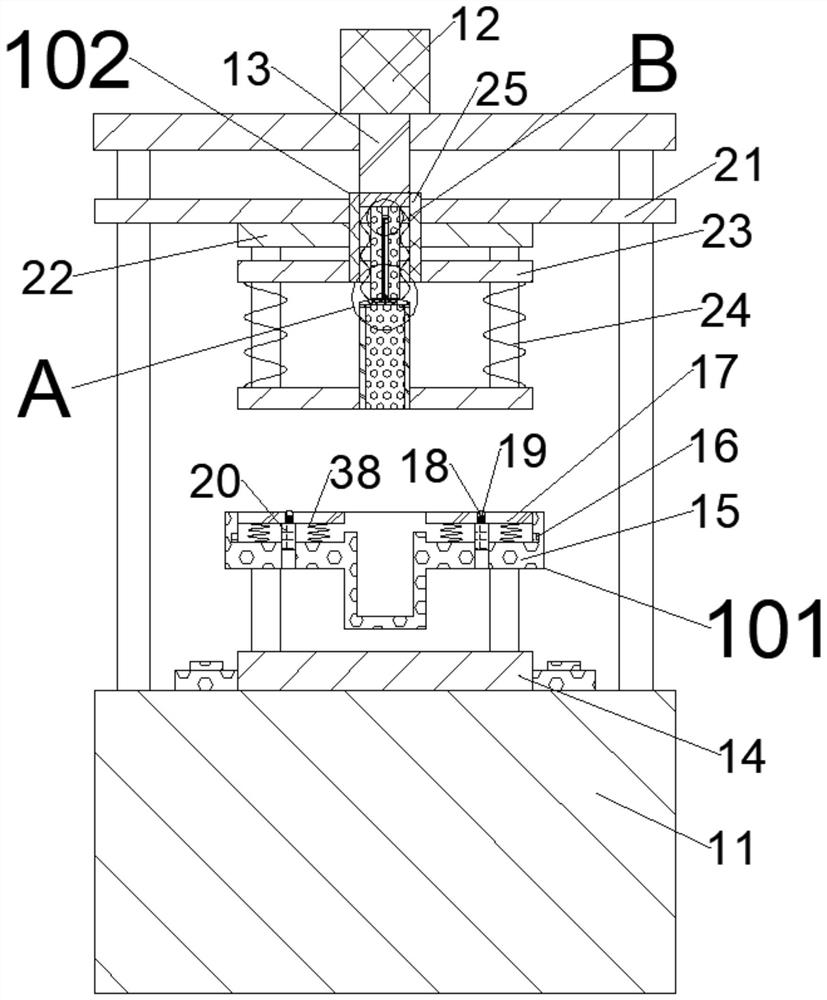

[0019] combined with Figure 1-4 The anti-deformation punching equipment for processing sheet metal parts includes a punching machine housing 11, and the punching machine housing 11 is provided with a die mechanism 101, and the die mechanism 101 is used for detecting the sheet metal parts in the present invention. Thickness and make corresponding changes;

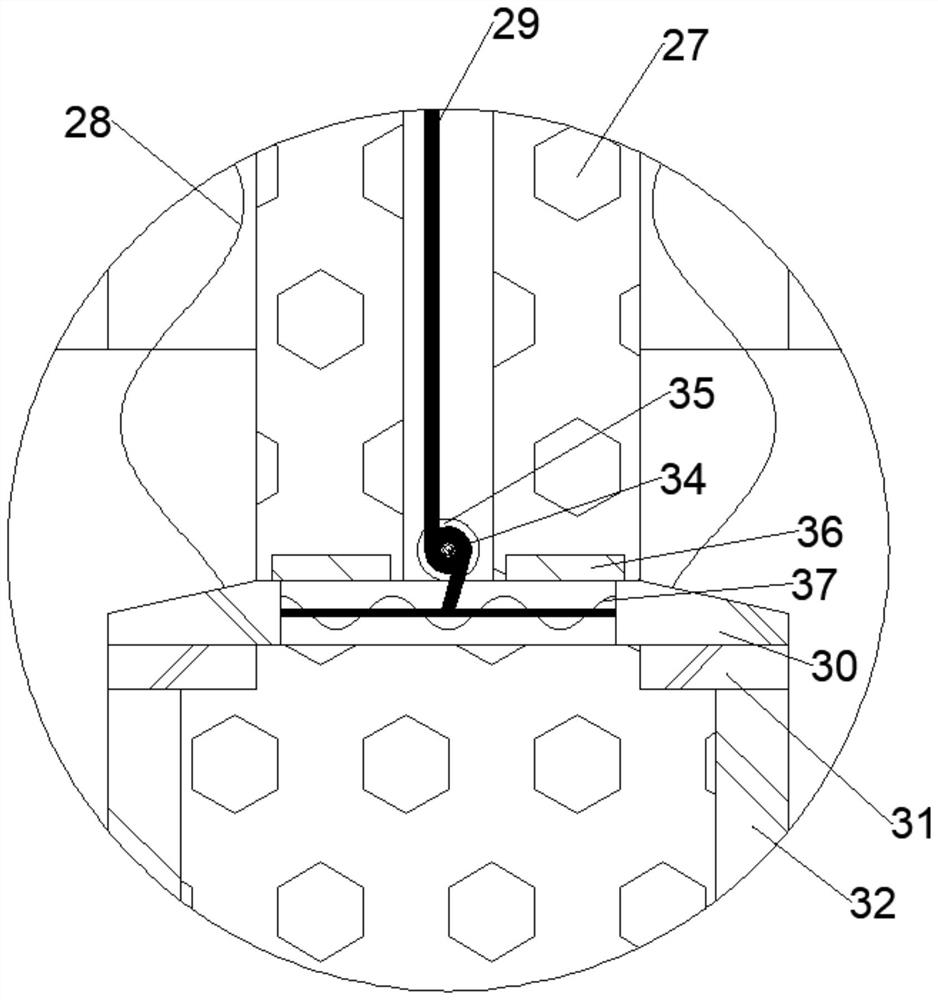

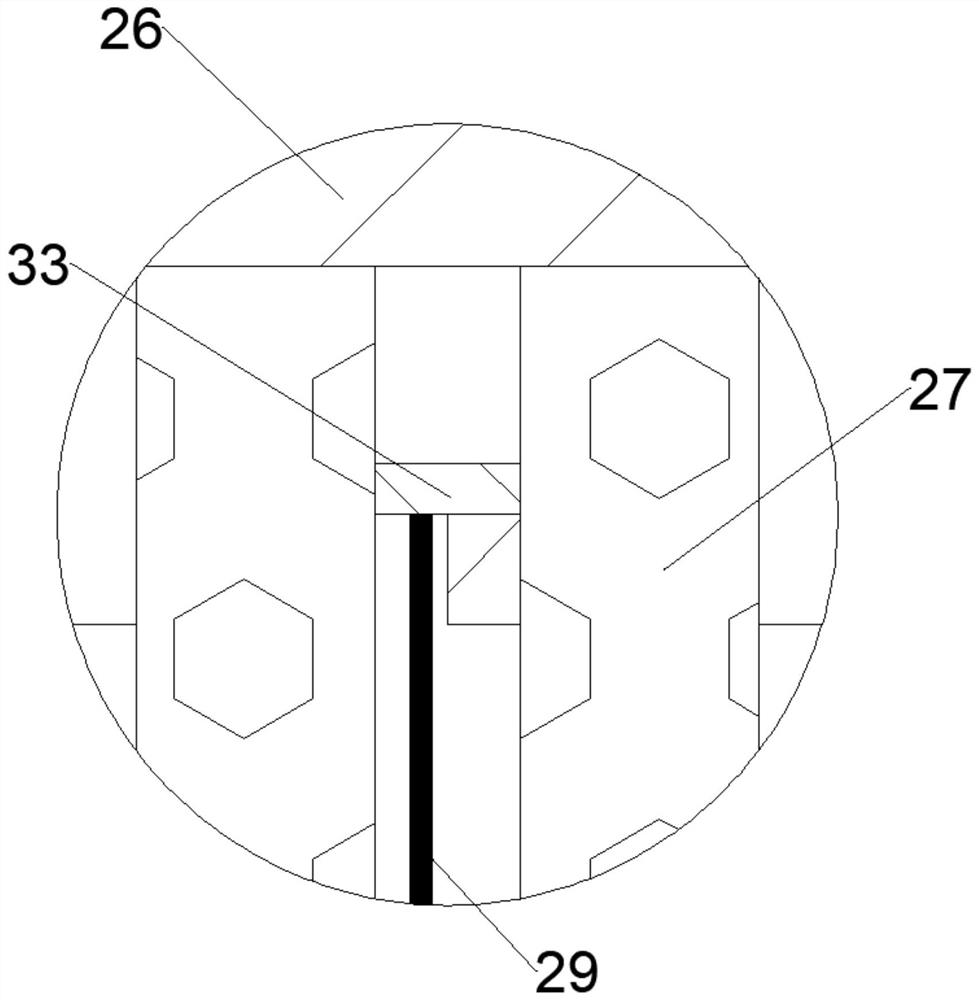

[0020] The die mechanism 101 is correspondingly provided with a punch mechanism 102, and the punch mechanism 102 includes a hydraulic cylinder 12 fixedly connected to the stamping machine housing 11, the hydraulic cylinder 12 controls a hydraulic rod 13, and the hydraulic cylinder 12 is controlled by a hydraulic rod 13. The rod 13 is fixedly provided with an electromagnet 26, the described electromagnet 26 is fixedly provided with a stamping rod 27, and the stamping rod 27 is slidably provided with a stamping connecting rod 31, and the stamping connecting rod 31 and the stamping rod 27 is connected by a return spring 28, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com