Total pressure distortion generator

A distortion generator and total pressure technology, applied in the testing of instruments, engines, and testing of machinery/structural components, etc., can solve problems such as insufficient reflection of multiple low-pressure areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific drawings and embodiments.

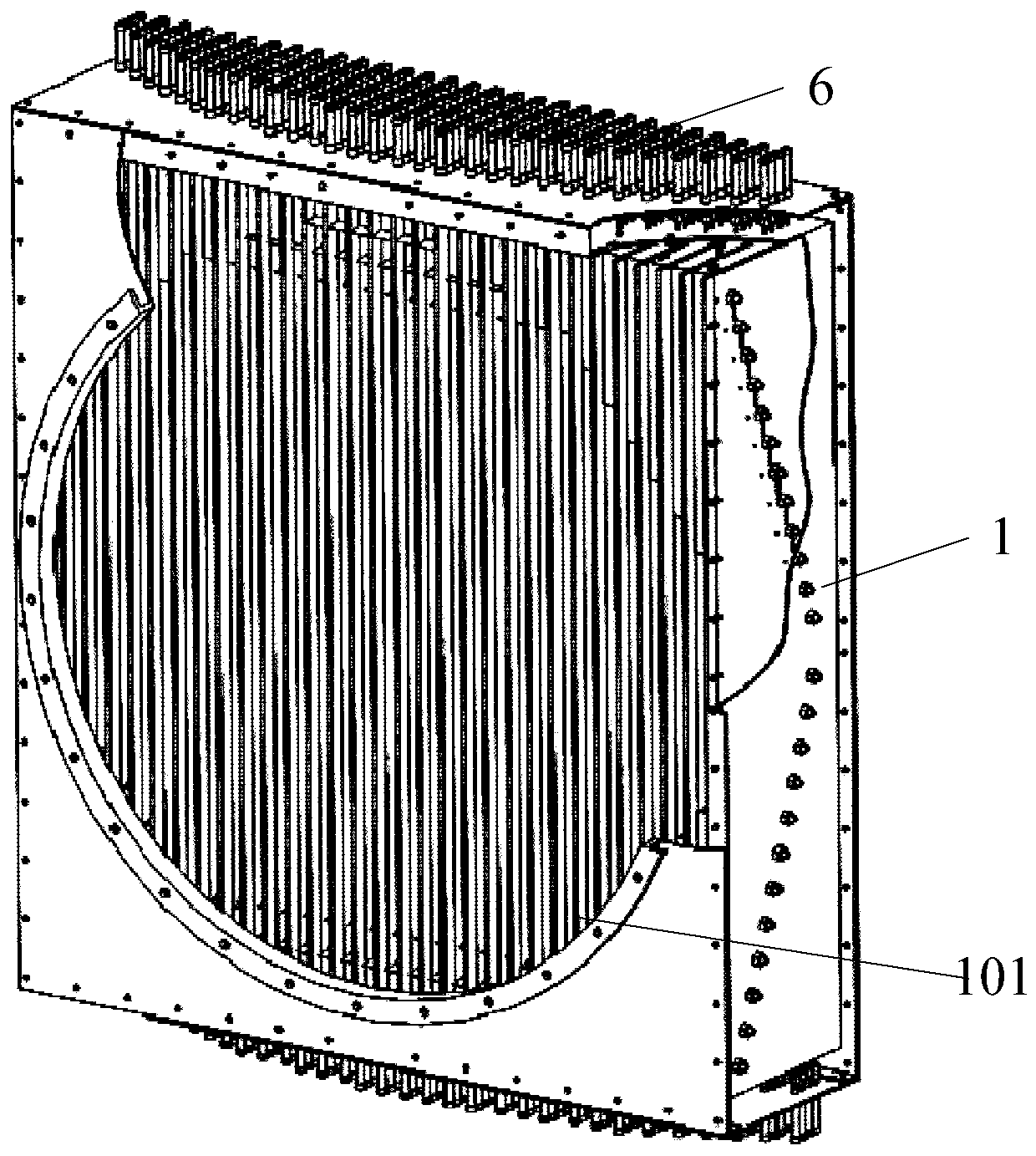

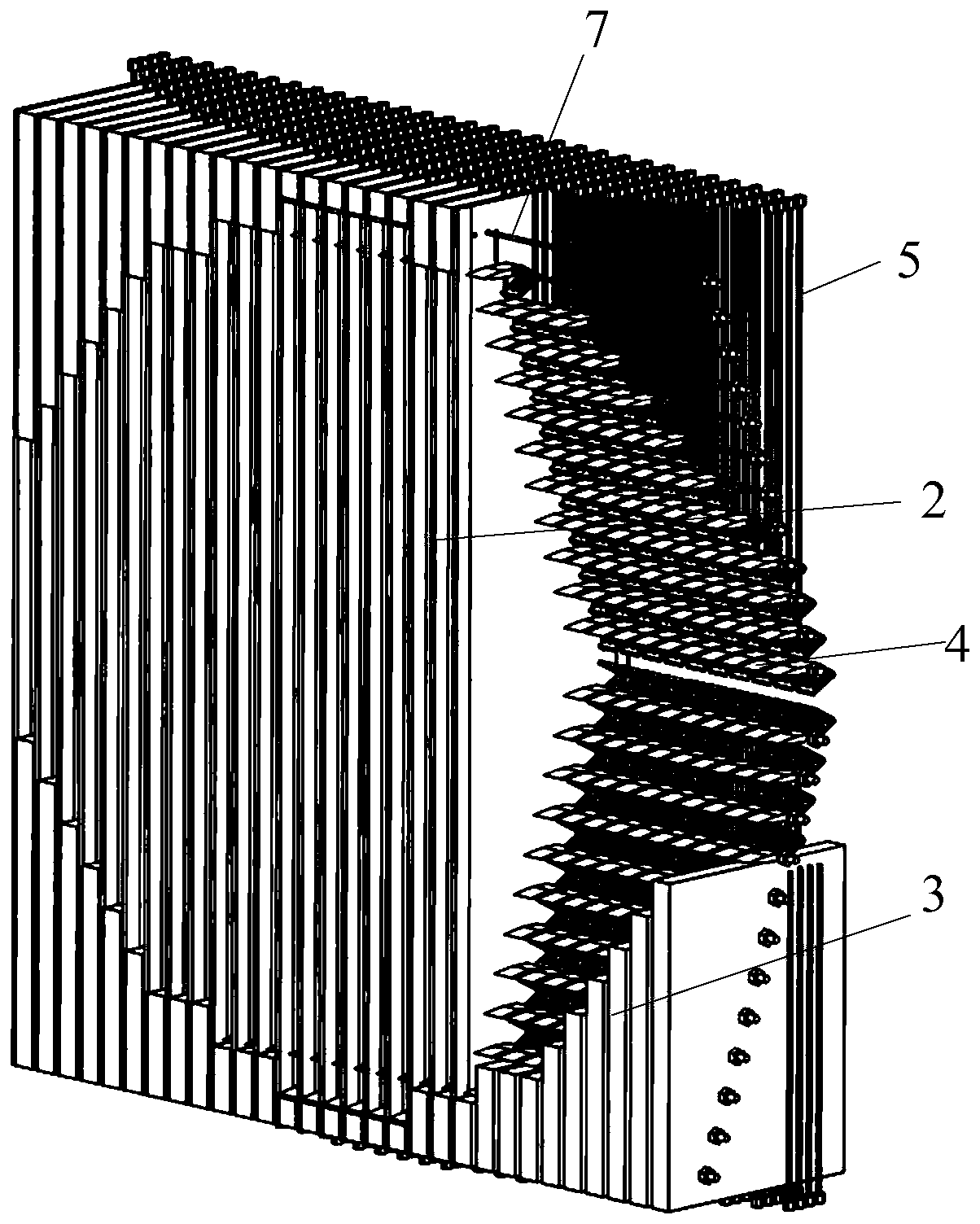

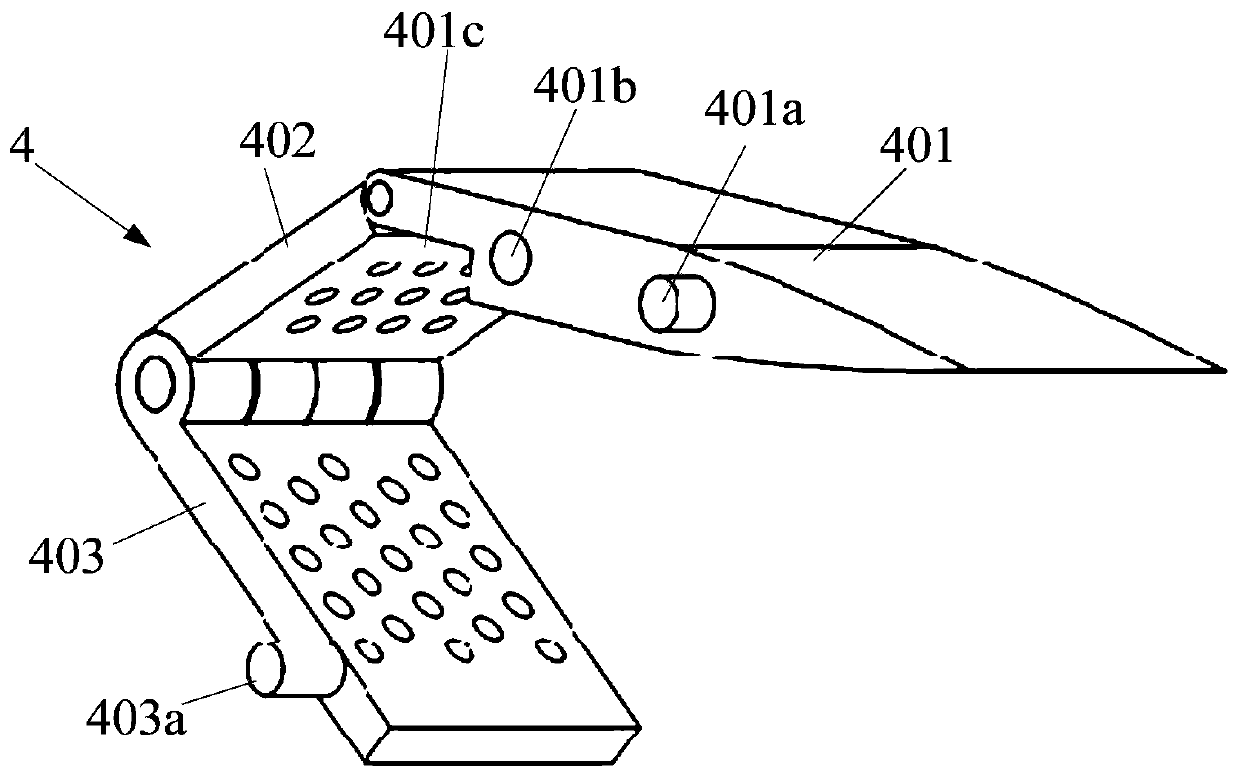

[0034] A total pressure distortion generator proposed by an embodiment of the present invention includes a frame body 1, a vertical streamlined hollow splint 2, a blocking partition 3, a distortion element 4, a push rod 5, and a cylinder assembly 6;

[0035] The front plate and the rear plate of the frame body 1 are provided with an opening 101 corresponding to the required air flow cross-sectional shape, for example, the opening 101 can be circular, and the shape of the opening 101 is generally consistent with the cross-sectional shape of the engine inlet outlet;

[0036] The vertical streamlined hollow splints 2 are installed parallel to each other between the front plate and the rear plate of the frame body 1; the inner space of the vertical streamlined hollow splints 2 is used for installing push rods 5; each vertical streamlined hollow splints 2 are install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com