Table leg and cross beam connecting structure, table leg frame and table

A connection structure and table leg technology, which is applied in the field of table frames, can solve problems such as cumbersome installation procedures, inconvenient use, and complicated connection structures, and achieve the effect of detachable connection and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

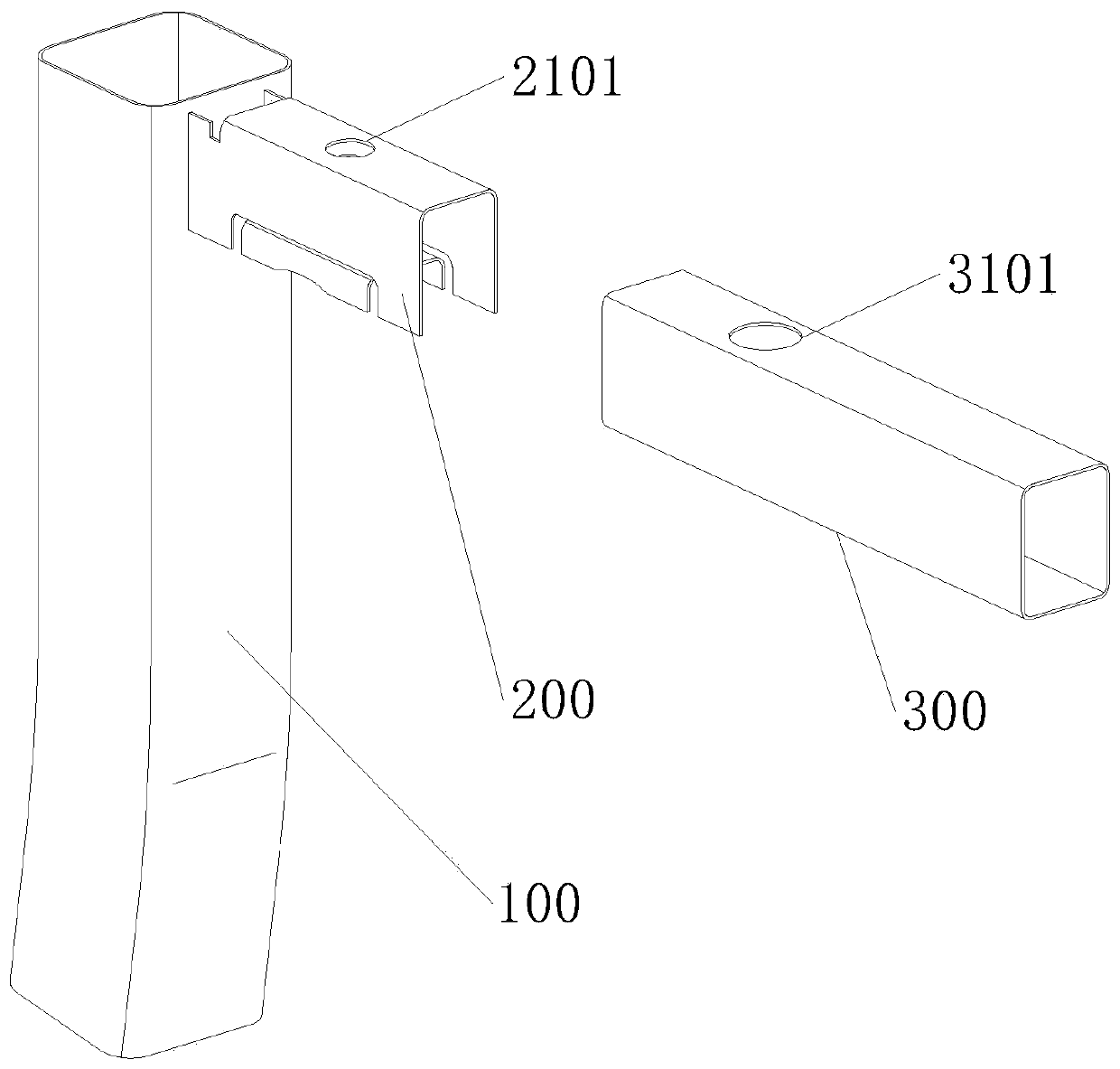

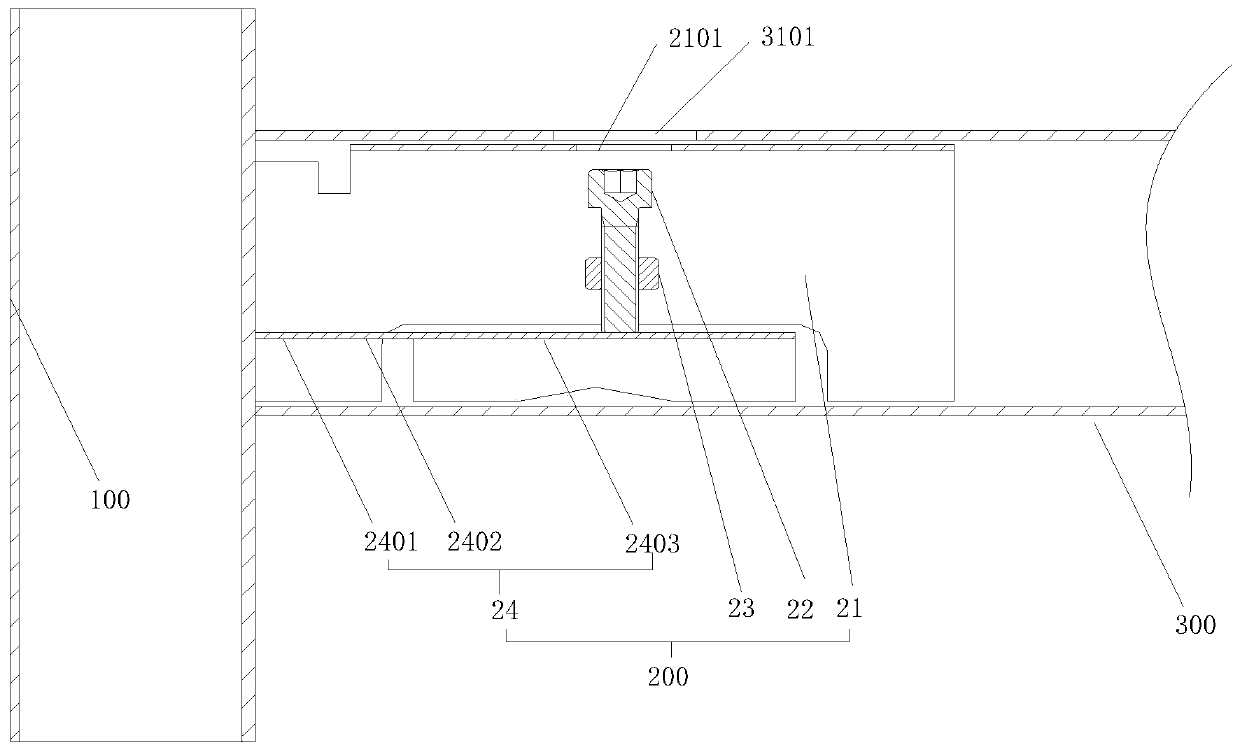

[0027] A connection structure between table legs and beams, such as Figure 1-Figure 7 As shown, it includes: a table leg 100, a tensioning assembly 200 and a beam 300, one end of the tensioning assembly 200 is fixed on the side of the table leg 100, the end of the beam 300 is a hollow structure or the whole is a hollow structure, the tensioning The component 200 is sheathed in the cavity of the beam 300 as a whole and tightened in the beam 300 through its own elastic deformation.

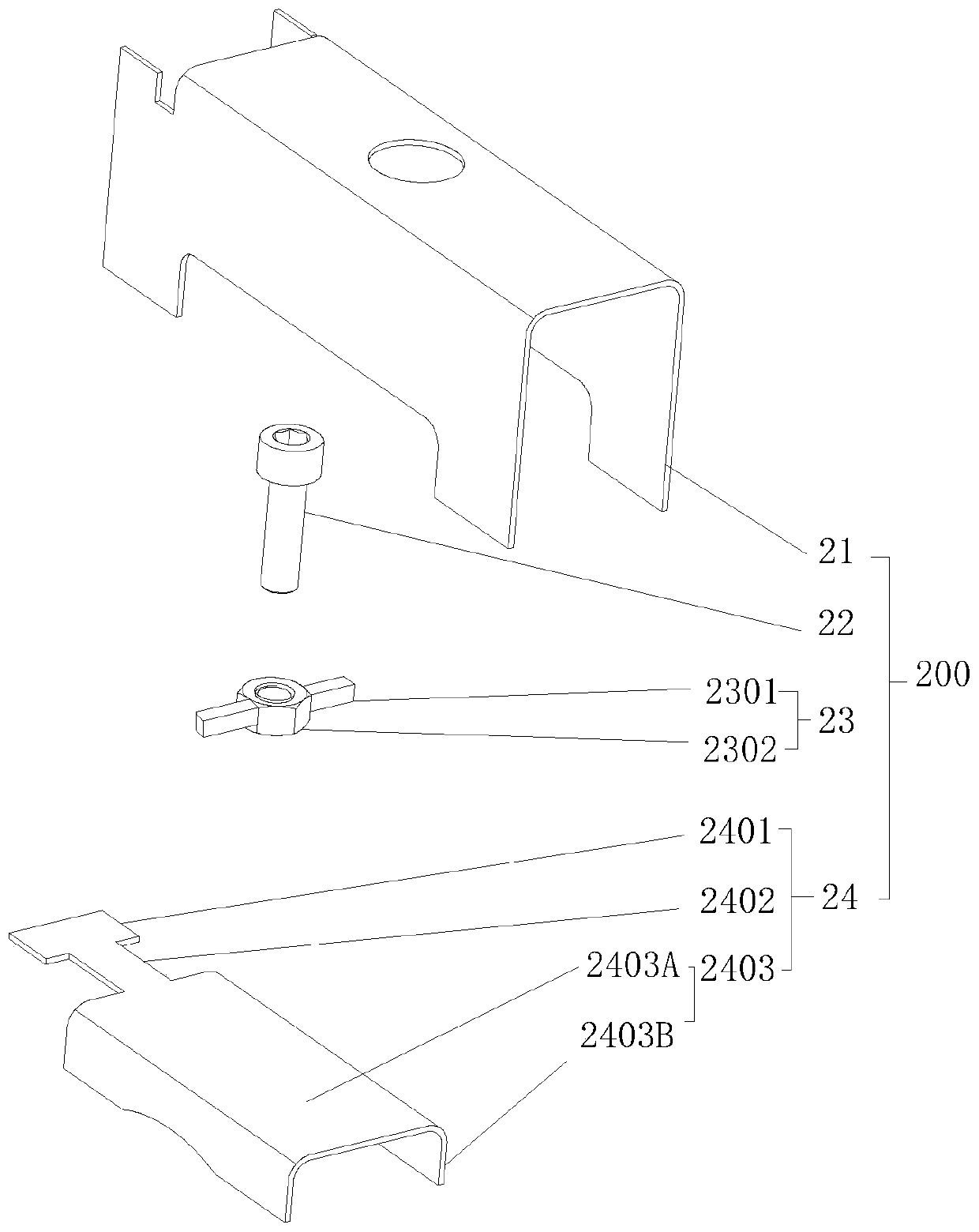

[0028] Specifically, tensioning assembly 200 includes:

[0029] The first subsection 21, one end of which is fixedly connected to the side of the table leg 100, can be fixed by welding, and the other ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap