A clean anti-overflow electric rice cooker

An electric rice cooker and cleaning technology, which is applied in the field of clean anti-overflow electric rice cooker, can solve the problems of poor anti-overflow function, reduce the cooking efficiency of the electric cooker, increase the difficulty of cleaning the cooker body, etc., so as to reduce the heat loss, improve the cleaning performance, and improve the cleanliness. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

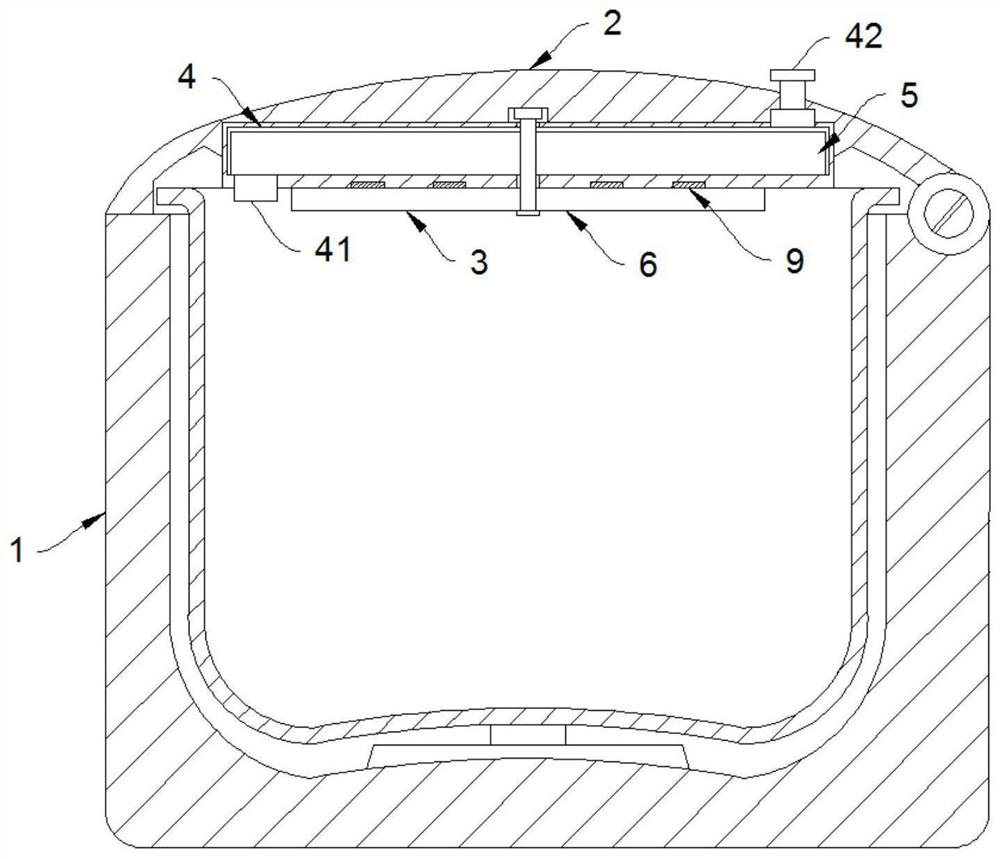

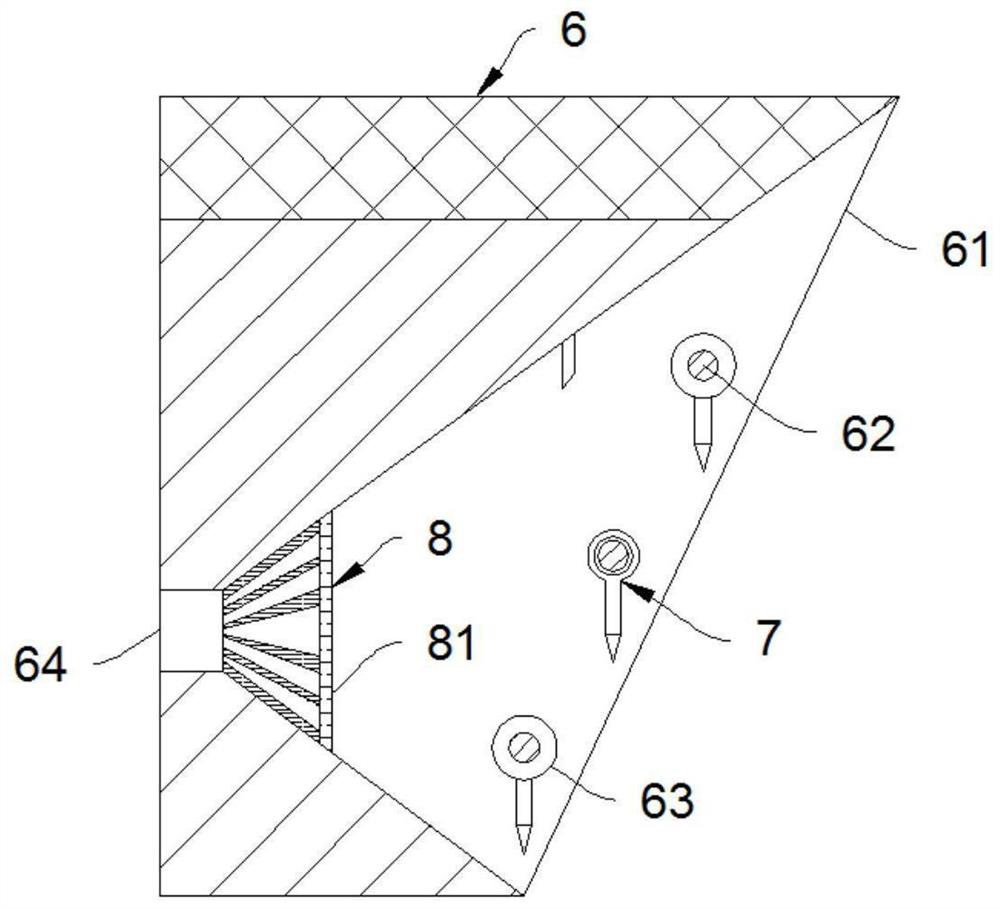

[0028] Such as Figure 1-2 As shown, a clean-type anti-overflow electric rice cooker includes a cooker body 1 and a cover body 2, the cooker body 1 and the cover body 2 are rotatably connected, the cover body 2 is provided with a cleaning device 3, and the cleaning device 3 includes a hot air chamber 4 and an air fan 5 And cleaning plate 6, it should be noted that the hot gas chamber 4 adopts a cylindrical structure, the fan blade of the air fan 5 adopts a rectangular structure, the length dimension of the fan blade is slightly smaller than the radius dimension of the hot gas chamber 4, and the height dimension of the fan blade is slightly smaller than The height dimension of the hot gas chamber 4 makes the fan blades can make good use of the hot gas in the pot body 1 to rotate.

[0029] Further, the end of the hot gas chamber 4 close to the pot body 1 is provided with an air inlet 41, and the end of the hot gas chamber 4 away from the pot body 1 is provided with an air outlet...

Embodiment 2

[0037] Such as image 3 Shown, the difference between this embodiment and embodiment 1 is:

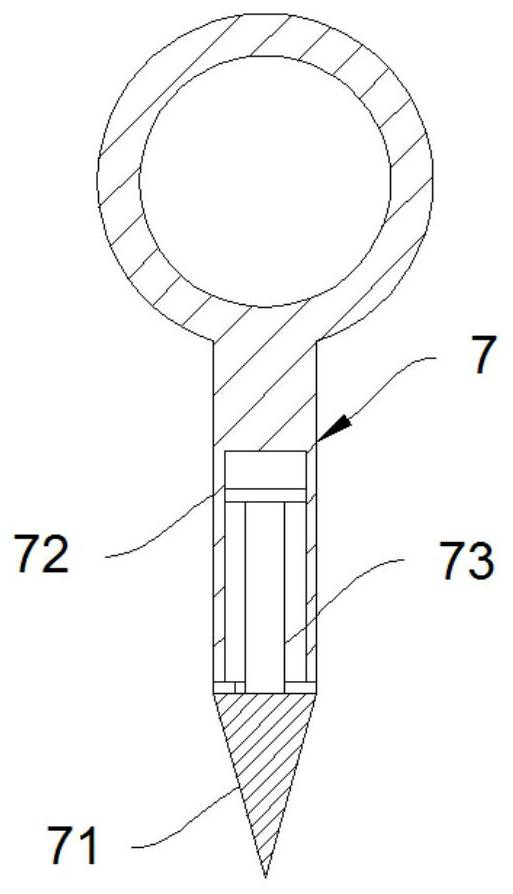

[0038]In order to prevent the defoaming needle 7 from rotating and defoaming, a small amount of air bubbles may adhere to the defoaming needle 7 and reduce the defoaming efficiency of the defoaming needle 7. The defoaming needle 7 is divided into needles 71 and the needle body 72. Only the needle head 71 is made of ferromagnetic material. The needle body 72 is provided with a sliding groove. plate, to prevent the needle head 71 from falling off during the rotation process, the needle head 71 and the magnetic block 9 are arranged in cooperation, so that when the defoaming needle 7 moves to the bottom of the magnetic block 9 under the drive of the cleaning plate 6, the needle head 71 of the defoaming needle 7 is on the magnetic block Under the attraction of 9, it rotates and rises. When the defoaming needle 7 is away from the bottom of the magnetic block 9, the needle head 71 swings und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com