Tractor, pipe tool drift diameter device and method

A tractor and diameter technology, used in earth-moving drilling, wellbore/well components, etc., can solve the problems of operator's hand injury, lack of passing tools, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

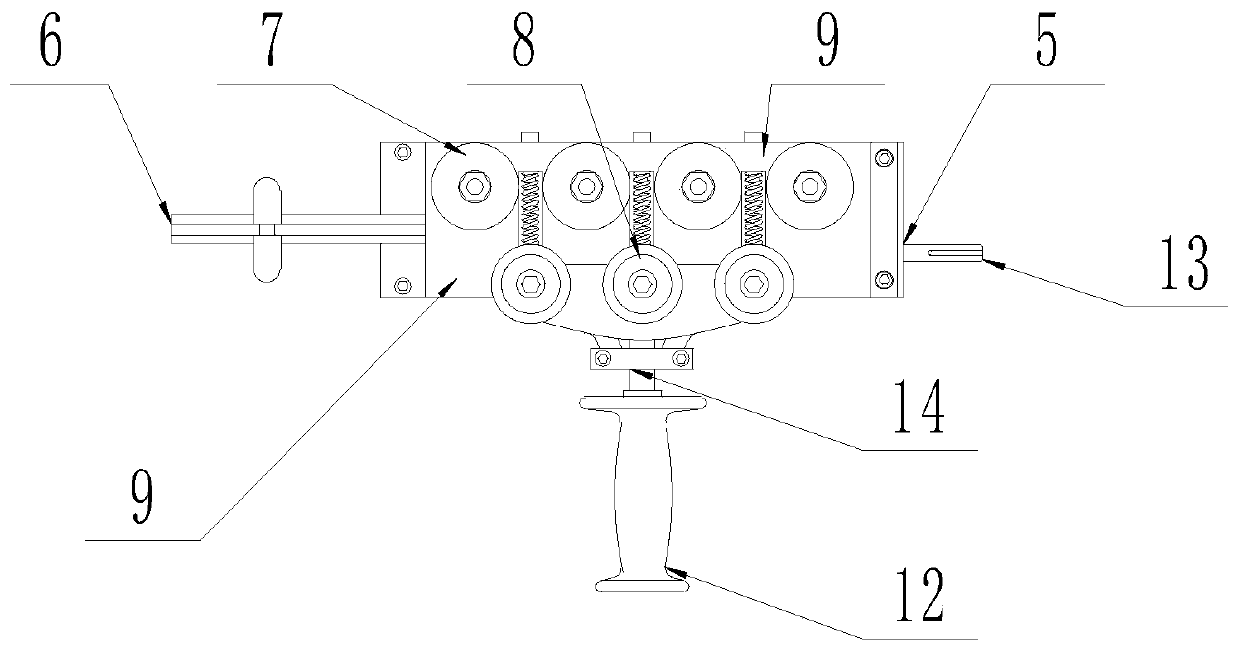

[0038] according to Figure 1-6 A retractor shown, including

[0039] Guide rope holder 10,

[0040] The moving guide rope rotating mechanism, the moving guiding rope rotating mechanism is connected in the guide rope fixing seat 10, the output end and the input end of the moving guiding rope rotating mechanism all extend to the outside of the guiding rope fixing seat 10;

[0041] Moving rope wheel 7, moving rope wheel 7 is arranged on the outside of fixed seat 10 and is connected with the output end of moving rope rotating mechanism;

[0042] A sliding part, the sliding part is connected on the guide rope fixing seat 10;

[0043] The static guide sheave group 8, the static guide sheave group 8 is connected with the sliding part, the static guide sheave group 8 and the dynamic guide sheave 7 are arranged alternately and are located on the same plane.

[0044] In actual use, firstly, the wire rope head is inserted into the tractor 4, so that the steel wire rope passes between...

Embodiment 2

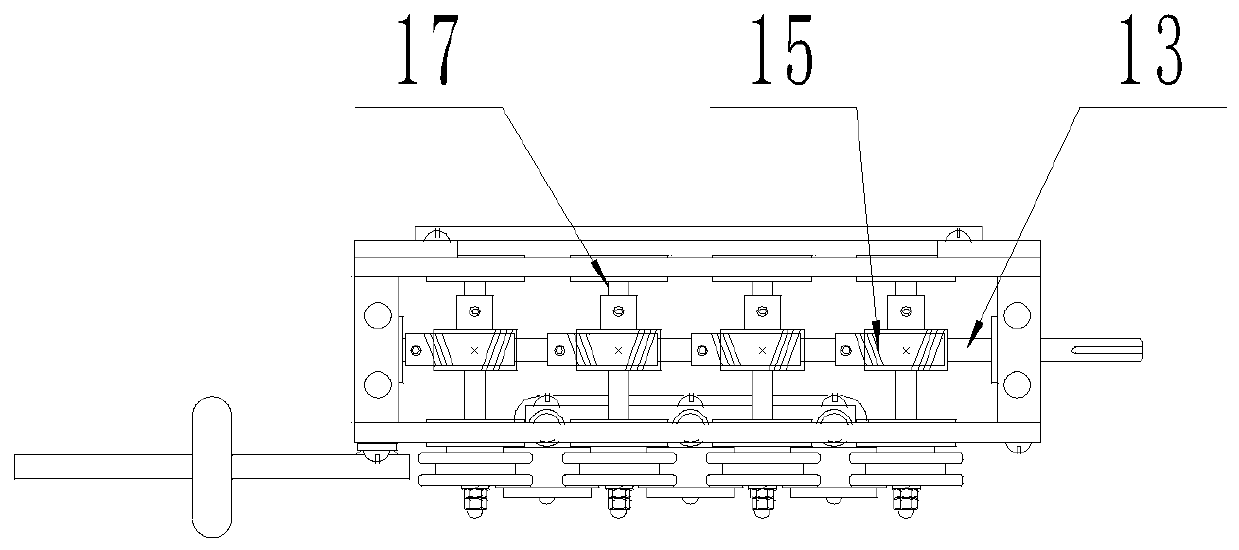

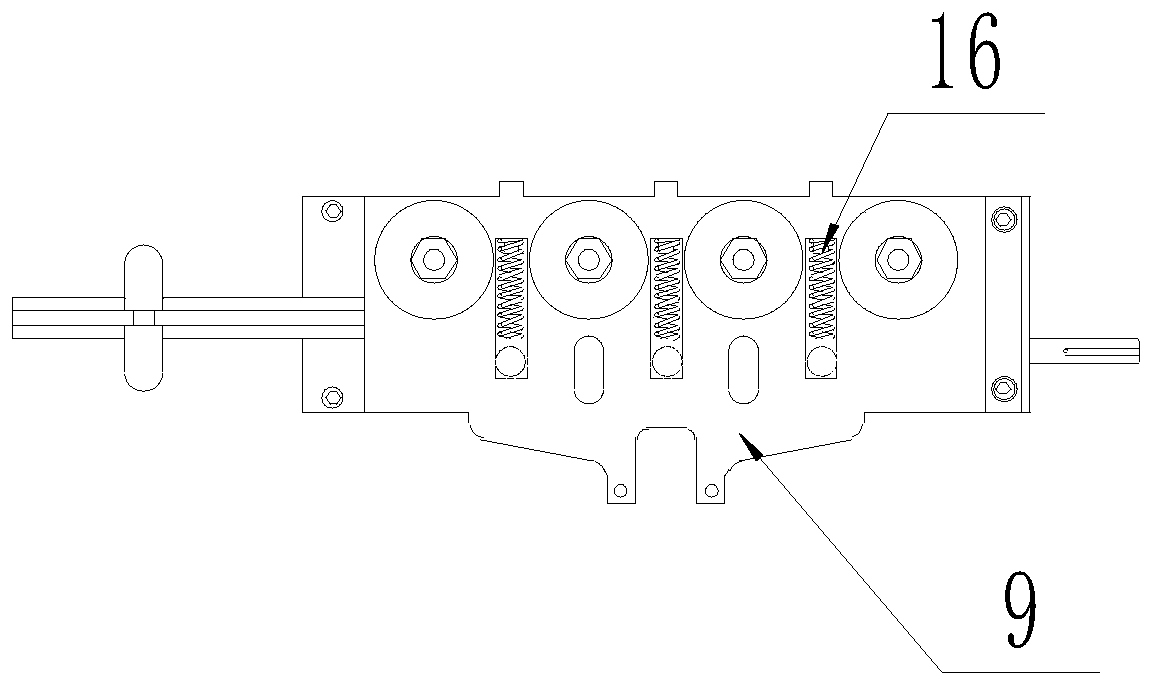

[0049] according to Figure 1-4 The retractor shown is different from the first embodiment in that: the guide wire fixing seat 10 is a rectangular frame structure with an open surface, and a first through hole is opened in the center of a side of the rectangular frame along the width direction 5. At least one pair of second through holes 11 are evenly and symmetrically opened on two opposite sides of the rectangular frame along the length direction; the moving guide rope rotation mechanism includes a moving connecting shaft 13, a driving gear 15 and a driven wheel shaft 17. The two ends of the connecting shaft 13 are respectively connected to the two sides of the guide rope fixing seat 10 along the width direction in rotation, and one end of the connecting shaft 13 extends to the outside of the guide rope fixing seat 10 through the first through hole 5, and is connected On the shaft 13, lead screws are arranged at equal intervals; the driven wheel shaft 17 is rotatably connect...

Embodiment 3

[0054] according to figure 2 and Figure 4 The shown tractor differs from the first embodiment in that: four pairs of second through holes 11 are provided, and the number of the second through holes 11 matches the number of 15 lead screws and driving gears.

[0055] In actual use, the number of setting of the leading screw and driving gear 15 can be determined according to the actual situation of the operation, and when the force of traction is large, the setting number of the leading screw and driving gear 15 is relatively large.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com