High-low terrain building foundation waterproof closing structure and process

A foundation and construction technology, applied in the field of basic waterproof closing, can solve the problems of waste of waterproof membrane 20 and large laying range of waterproof membrane 20, and achieve the effect of saving waterproof cost, reducing laying area and shortening construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

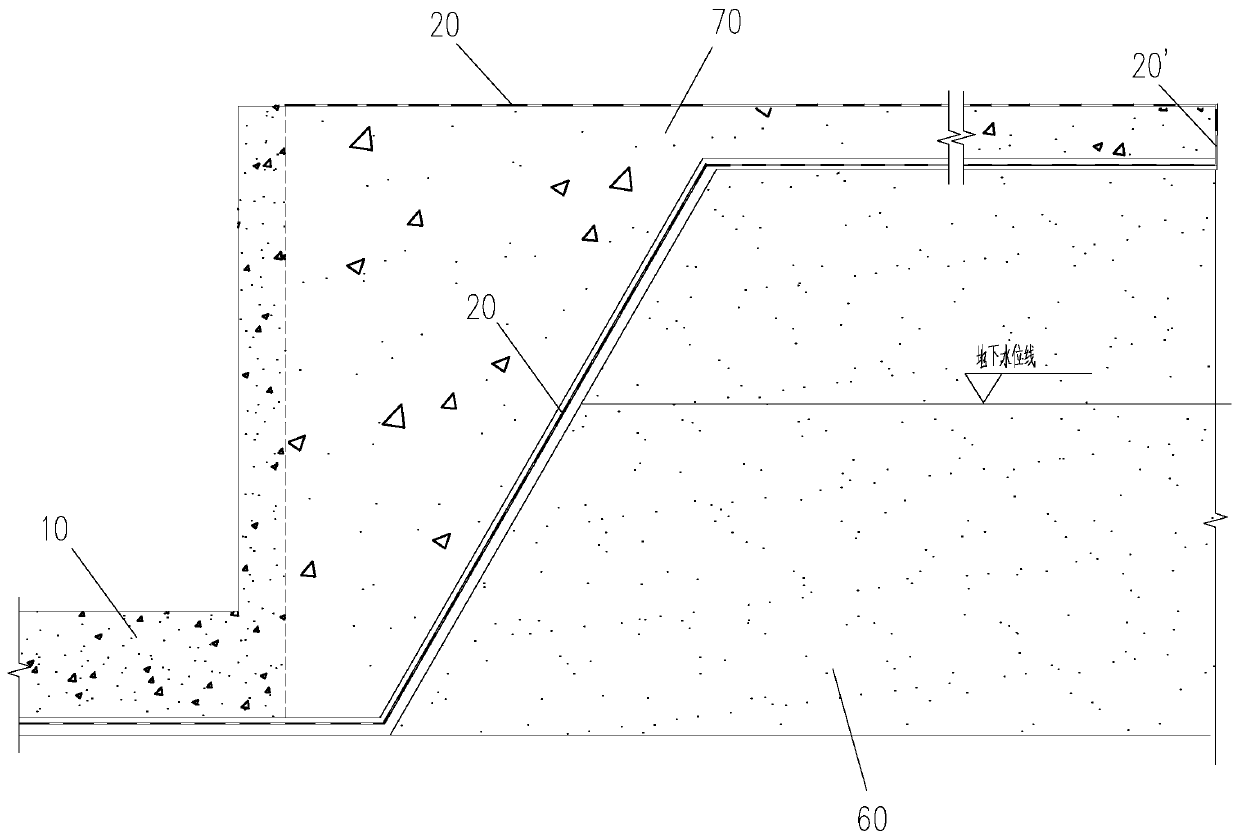

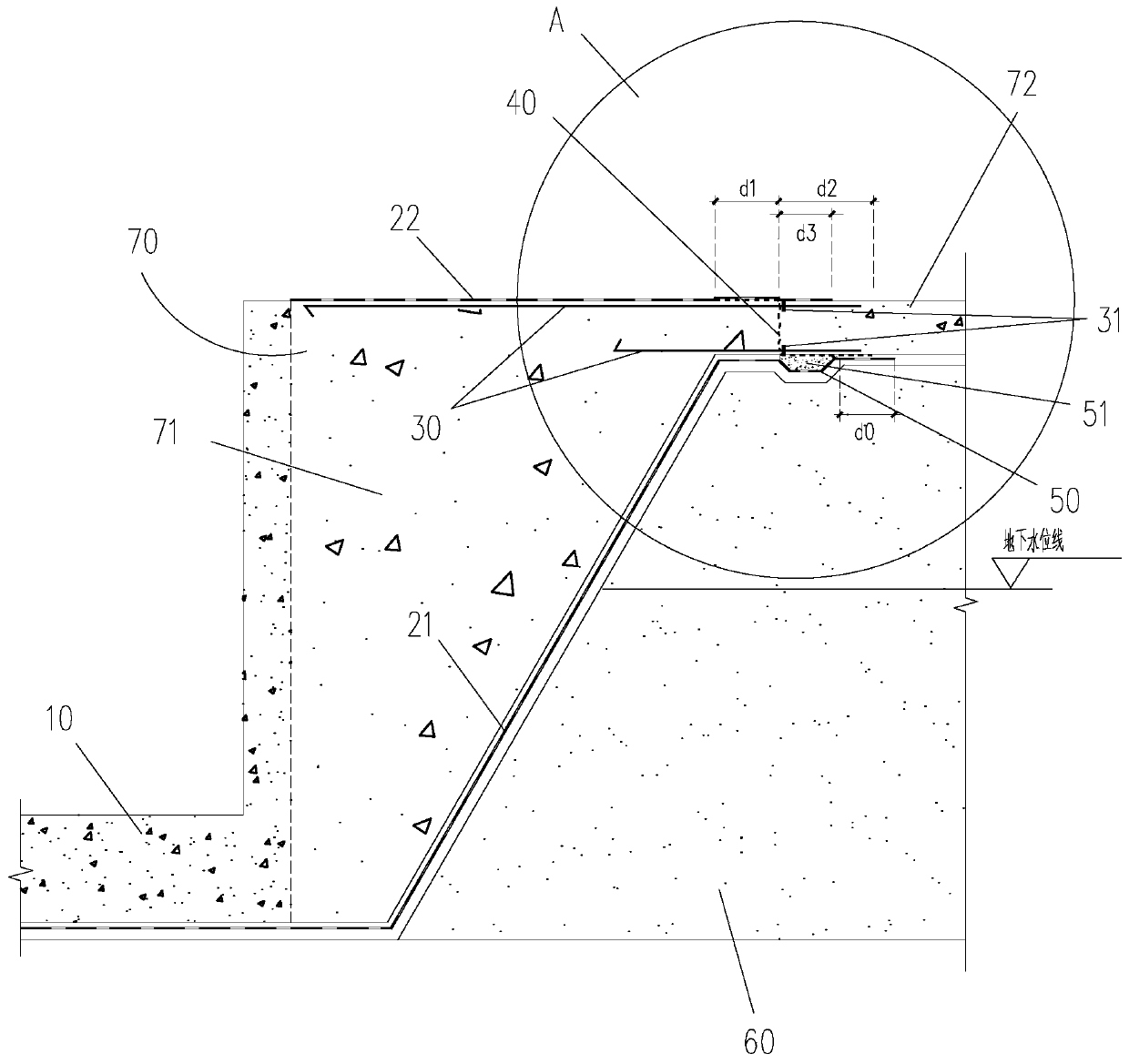

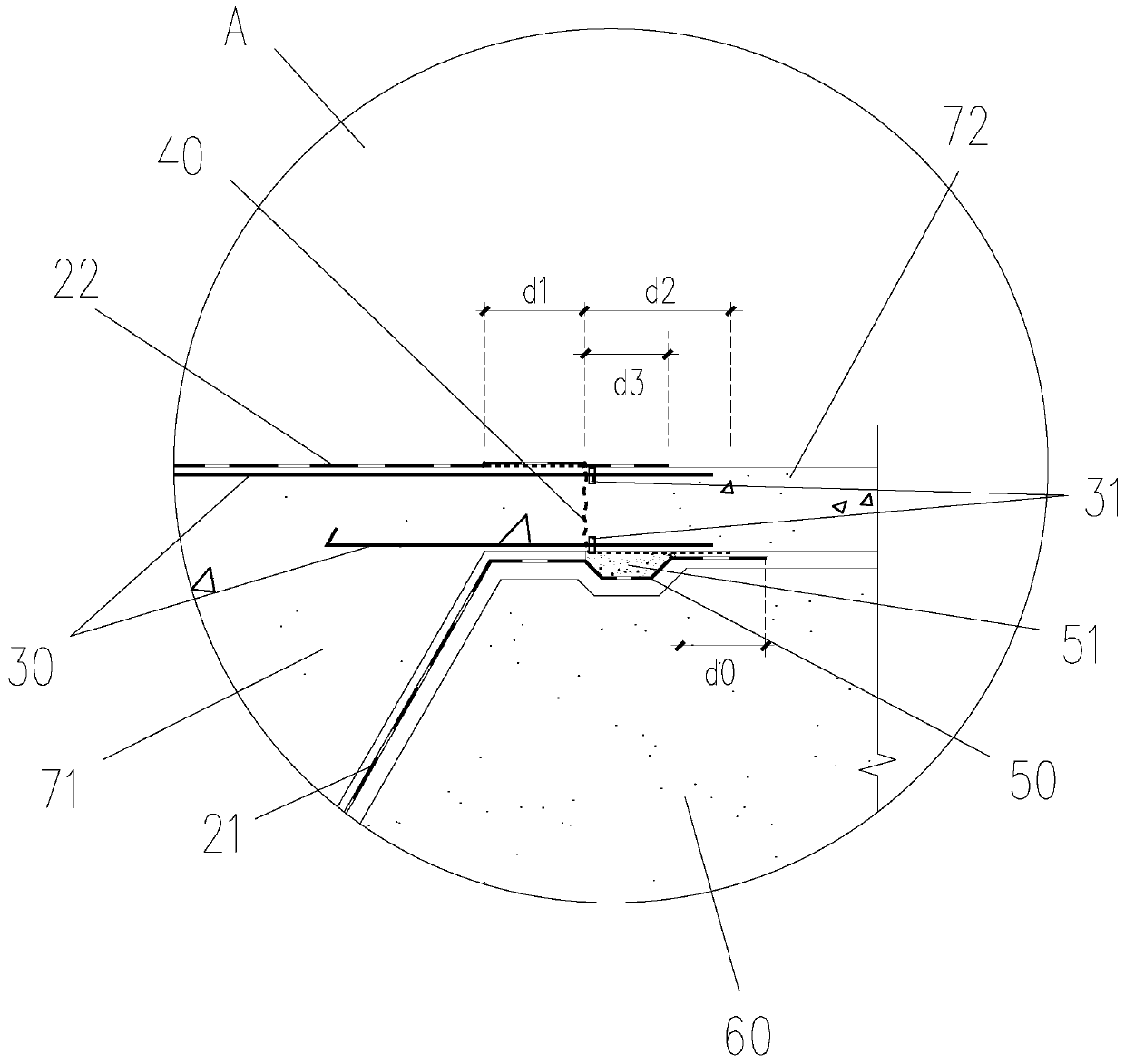

[0022] The waterproof closure structure of the high-low terrain building foundation of the present invention is arranged on the foundation 70 above the groundwater level among the foundation 10 below the groundwater level and the foundation 70 above the groundwater level where there is a difference in height. Such as figure 2 and image 3 As shown, the waterproof closure structure of the high and low terrain building foundation of the present invention includes a head and edge groove 50 dug near the edge of the top of the foundation pit 60; a head and edge groove 50 from the bottom of the foundation pit 60 to the top of the foundation pit The lower waterproof coiled material 21 is laid on the top; the fine stone concrete 51 is poured in the edge-cut groove 50 of the lower waterproof coiled material 21 for the edge-folded edge; the foundation 10 below the groundwater level constructed at the bottom of the foundation pit 60 At least two layers of waterproof paint 40 are painte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com