Fabricated suspended slidable scaffold assembly for old house transformation

A scaffolding and prefabricated technology, applied in the field of scaffolding, can solve the problems of reduced overall structural strength, rigidity and stability of scaffolding, unsuitable for renovation of old residential buildings, and inability of horizontal rods to pass through, so as to reduce the overall laying area and occupation. Small space, the effect of saving the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

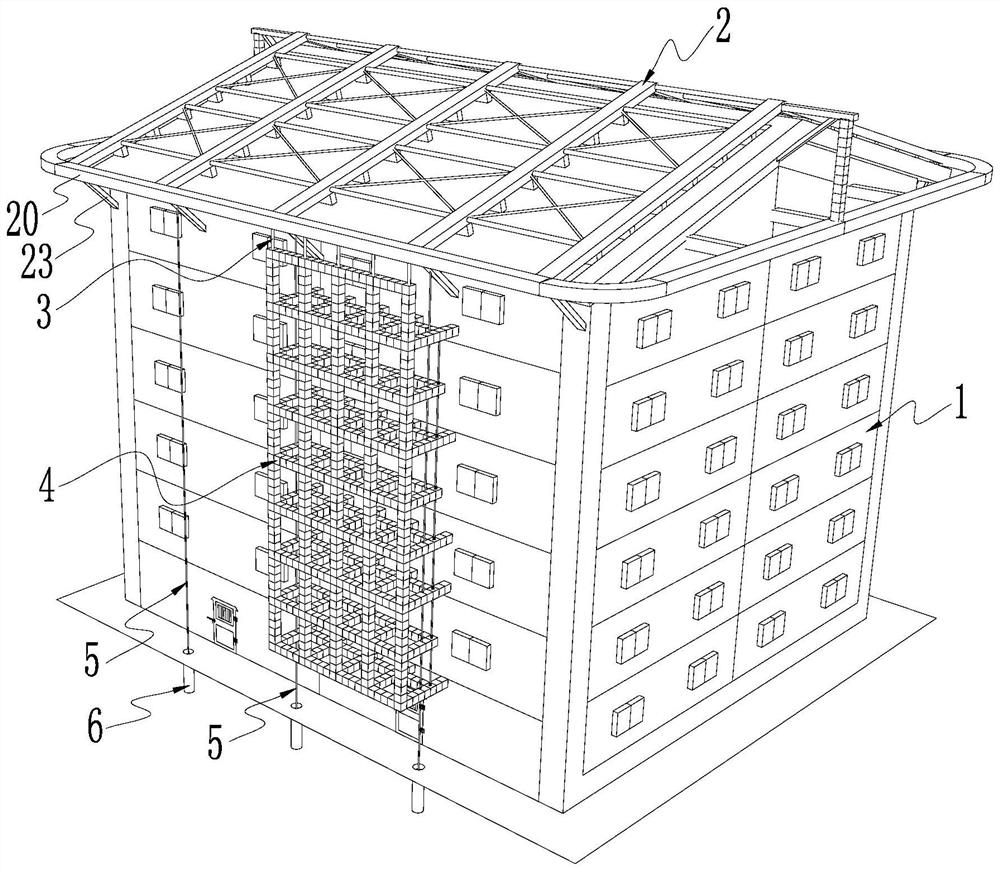

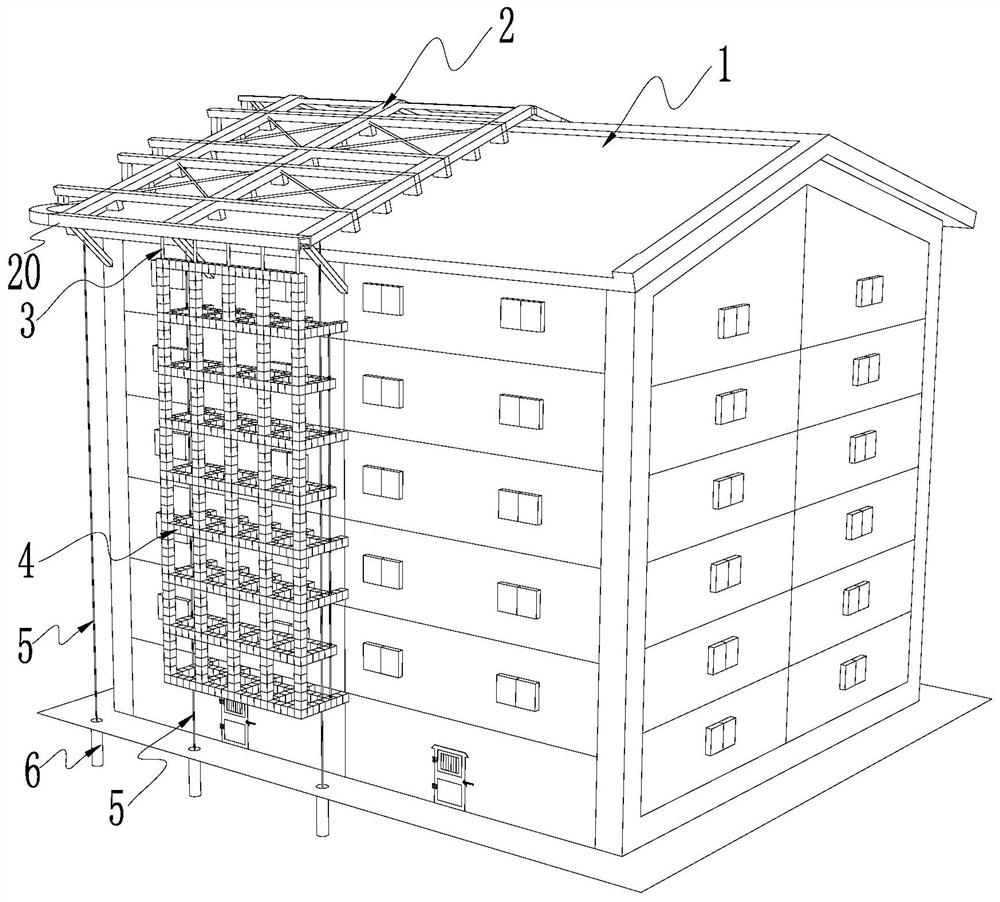

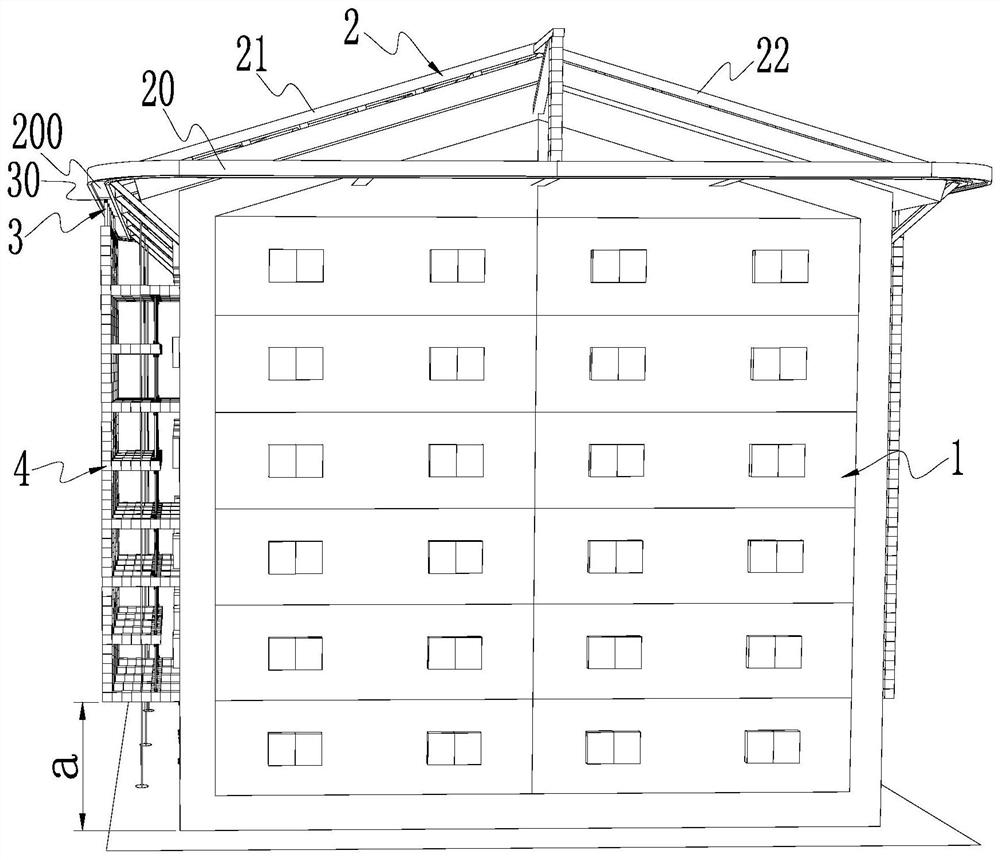

[0038] Such as Figure 1-Figure 3 As shown, an assembled suspended and slidable scaffold assembly for renovation of old houses includes a top support frame 2 , a connector 3 , a scaffold module 4 , stay cables 5 and ground piles 6 arranged on a building 1 .

[0039] Wherein, the main body of the top support frame 2 is erected on the roof of the building 1, and the top support frame 2 includes a sliding beam 20 protruding from the building 1, that is, the sliding beam 20 is outside the building 1; The building 1 is arranged circumferentially so that the sliding beam 20 surrounds the building 1; the connecting piece 3, one end of the connecting piece 3 is slidably arranged on the sliding beam 20; the scaffolding module 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com