Vibration type actuator and manufacturing method of vibration type actuator

A manufacturing method, vibration-type technology, applied in the direction of instruments, generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., can solve the problem of actuator performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

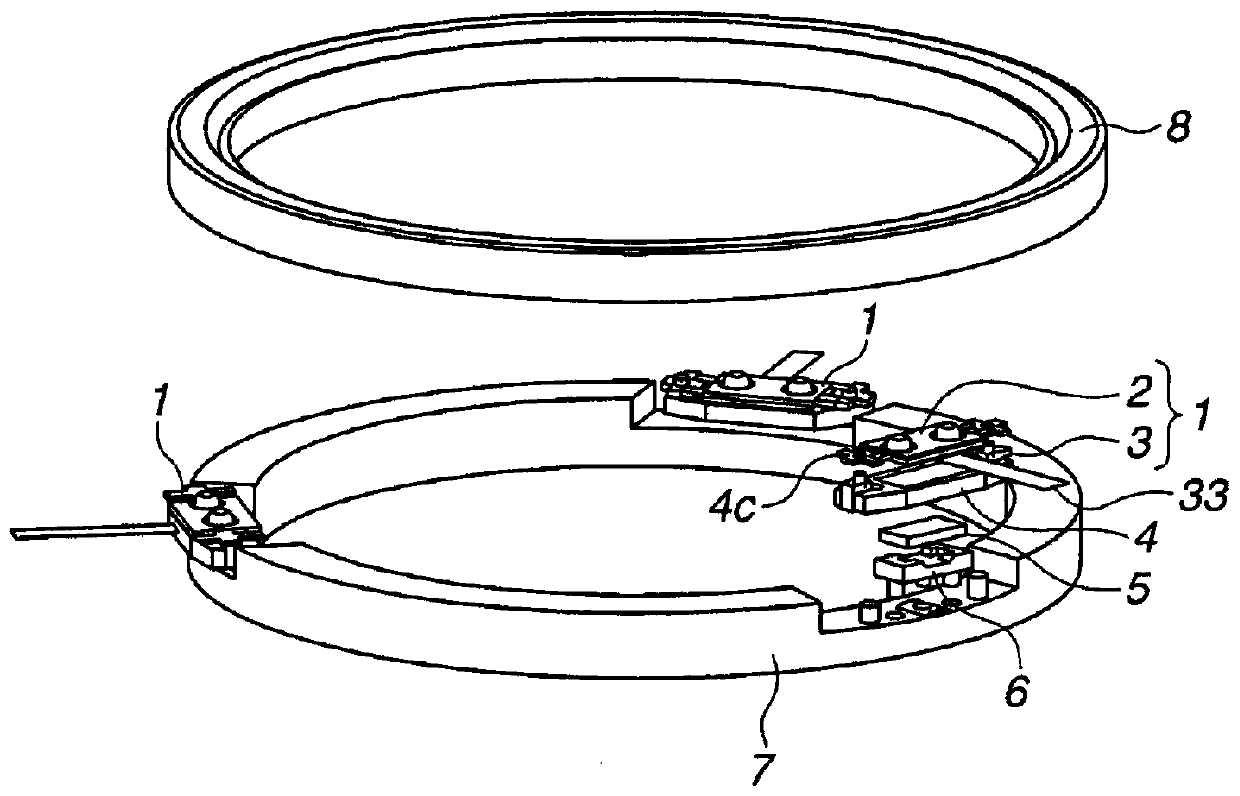

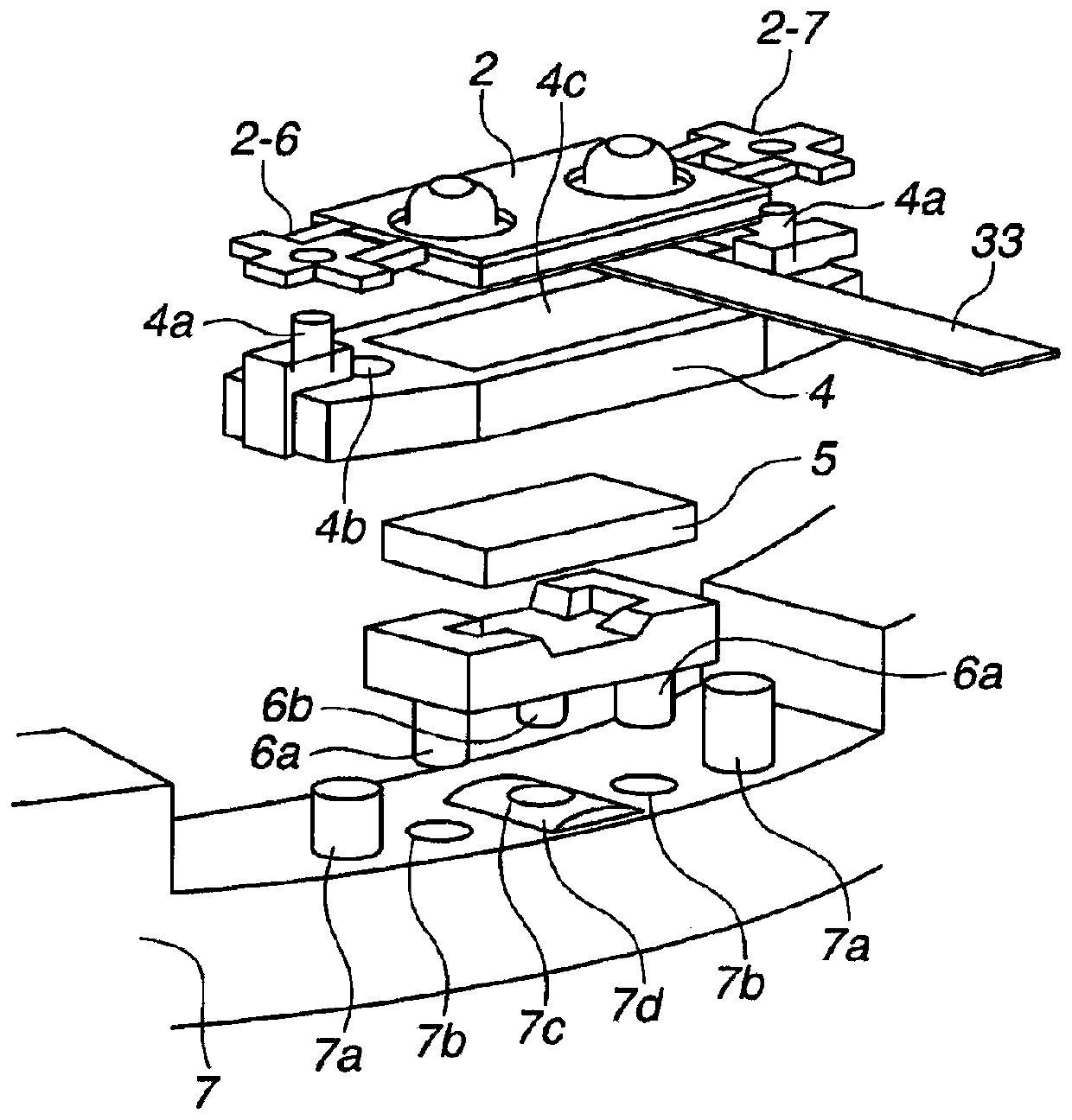

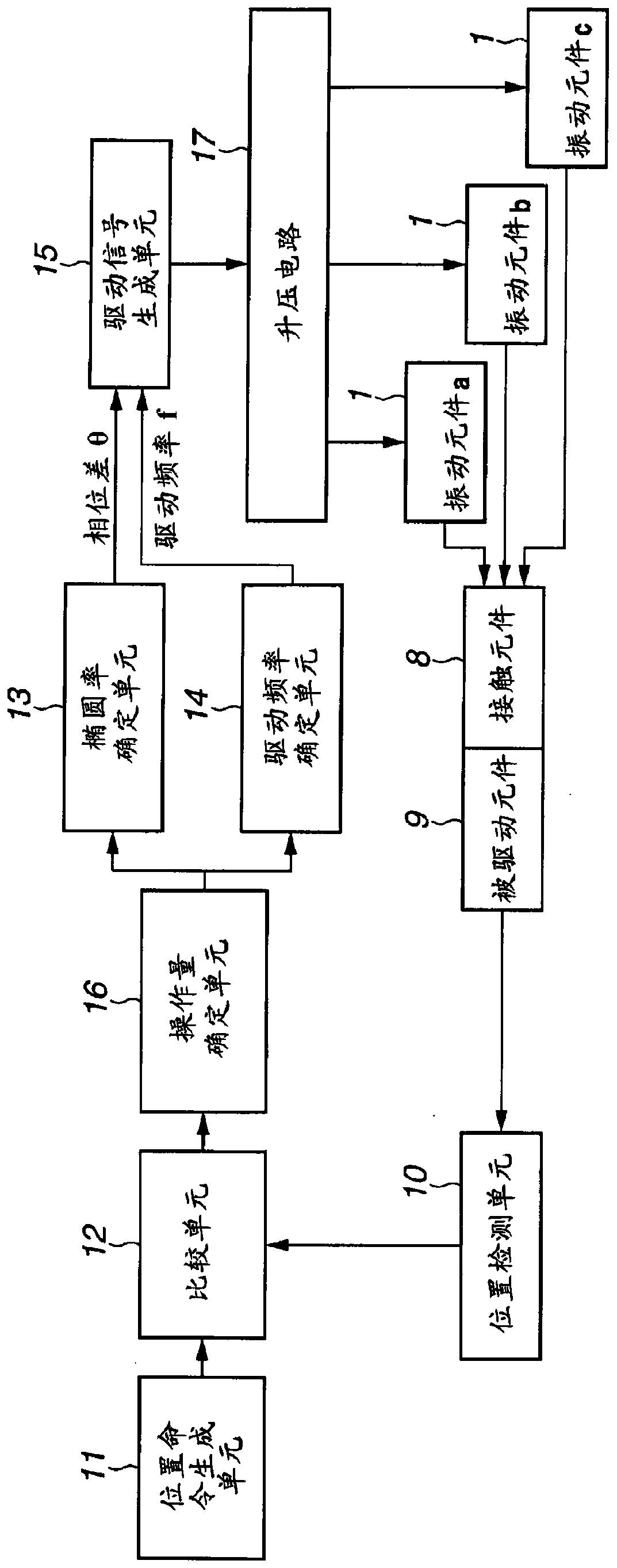

[0017] First, refer to Figures 8A to 9C General techniques are described.

[0018] Figure 8A is the plan view of the vibrating element, Figure 8B is a side view of the vibrating element. exist Figure 8A with 8B Among them, a vibrating element 1 includes an electric energy-mechanical energy conversion element (piezoelectric element) 3 having a rectangular (quadrilateral) thin plate shape and an elastic element 2 integrally bonded to (one plane of) the piezoelectric element 3 .

[0019] The elastic element 2 comprises a main part 2-3 and a support part 2-4.

[0020] The main part 2-3 comprises a base part 2-1 and two protrusions 2-2. The base portion 2 - 1 having a rectangular thin plate shape vibrates together with the piezoelectric element 3 . The protrusion 2-2 protrudes from one plane of the base portion 2-1 (the plane of the elastic member 2 opposite to the plane to which the piezoelectric element 3 is bonded). For example, as discussed in Japanese Patent Applic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com