Internal combustion engine with turbocharge arrangement

A technology of internal combustion engine and turbine, applied in the field of vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

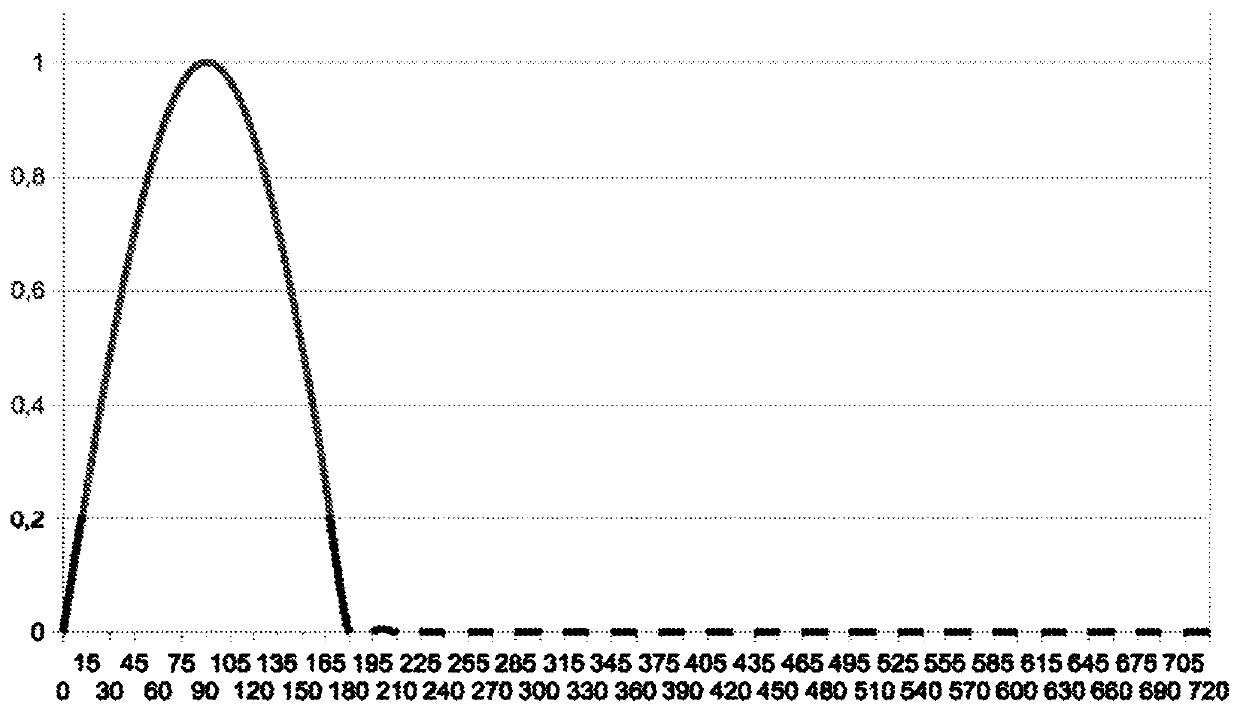

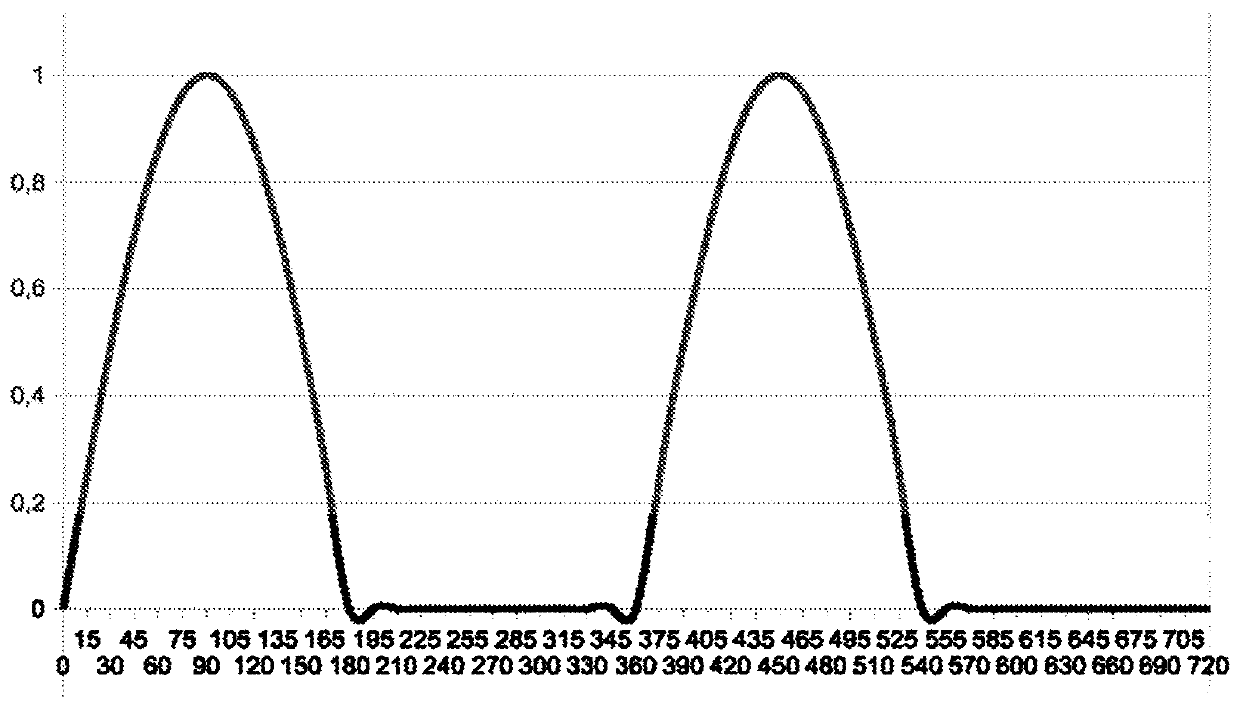

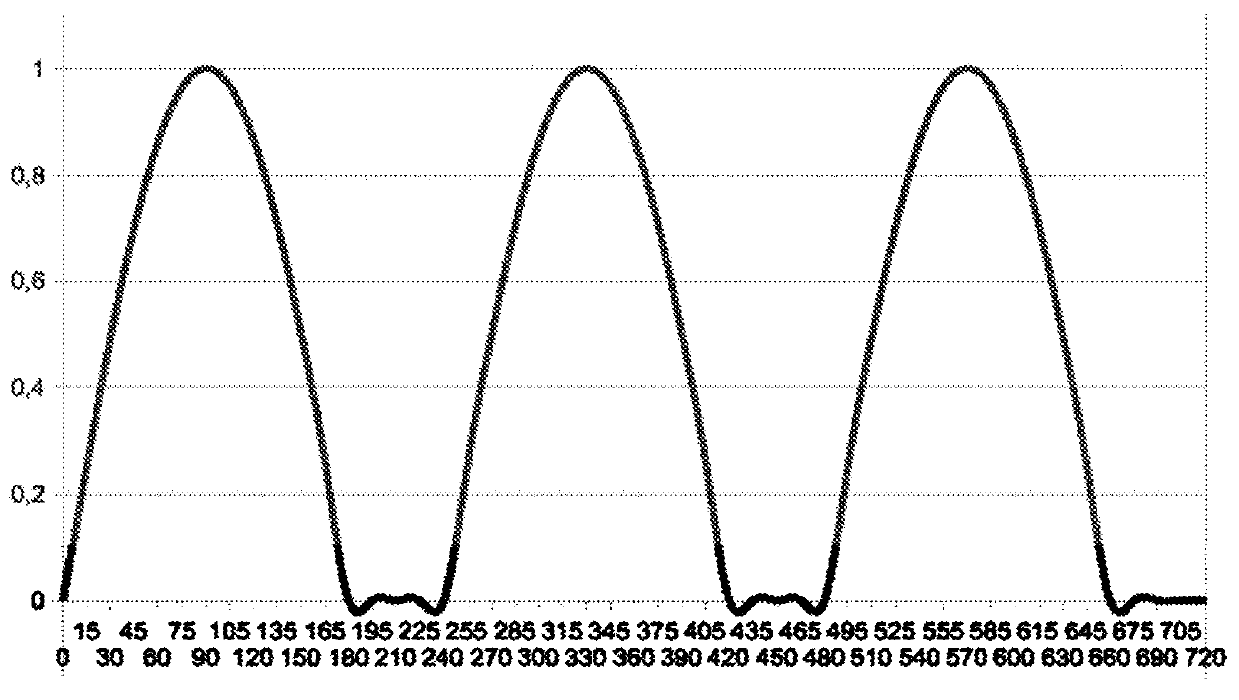

[0101] Figures 10a-10b schematically illustrate the exhaust flow from a 4-stroke engine with 2 cylinders and 1 exhaust cylinder. No fuel is burned in the exhaust cylinder and the cylinder is fully open towards the exhaust manifold and has no valves. The task of the exhaust cylinder is, first to receive part of the exhaust gas from one of the combustion cylinders (other part of the exhaust gas goes directly to the exhaust manifold / pipe), then wait for half a revolution of the engine, and the containment of the exhaust gas by the exhaust piston A portion is sent to the exhaust pipe and turbocharger, which then receives a portion of the exhaust gas from another burning cylinder, and repeats. This makes the exhaust manifold resonate at all revs.

[0102] A 4-stroke engine with 2 cylinders and 1 exhaust cylinder provides positive torque when the exhaust piston (away from the exhaust chamber) is depressed, which makes the torque curve change less compared to a conventional 2-cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com