Guy system for offshore floating crane

A floating crane and stabilizing cable technology, applied in the field of floating crane system, can solve problems such as damage, increase in the tension of the stabilizing cable wire rope, and damage to the stabilizing cable system, and achieve the effects of prolonging the service life, easy replacement, and protection from wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

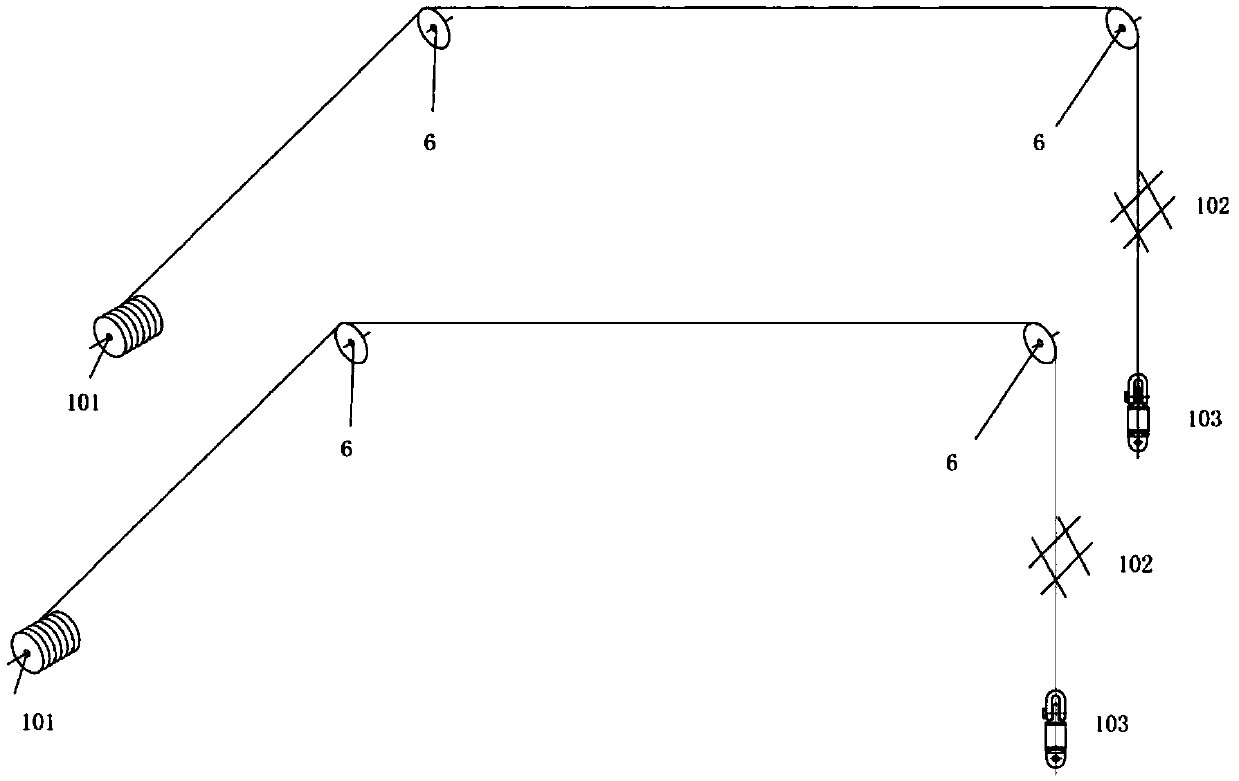

[0043]A new type of wire rope system for offshore floating cranes, including two sets of the same wire rope system for wire ropes arranged on the crane: left wire rope system and wire rope system for right wire rope, such as figure 1 As shown, the two sets of systems have the same structure, and both include a reel and its driving mechanism 101, a transition pulley 6, a well roller 102, a shackle and an anti-rotation sleeve 103, and the reel and its driving mechanism 101 are placed on the crane On the turntable under the boom or at the root of the boom, the transition pulley 6 and the well roller 102 are all installed on the boom, and the steel wire rope 4 passes through the transition pulley and the well roller after unwinding from the drum Connect the shackle and the anti-rotation sleeve, and the steel wire rope 4 leaves the arm frame through the well-tac-toe roller to connect with the hoisting object.

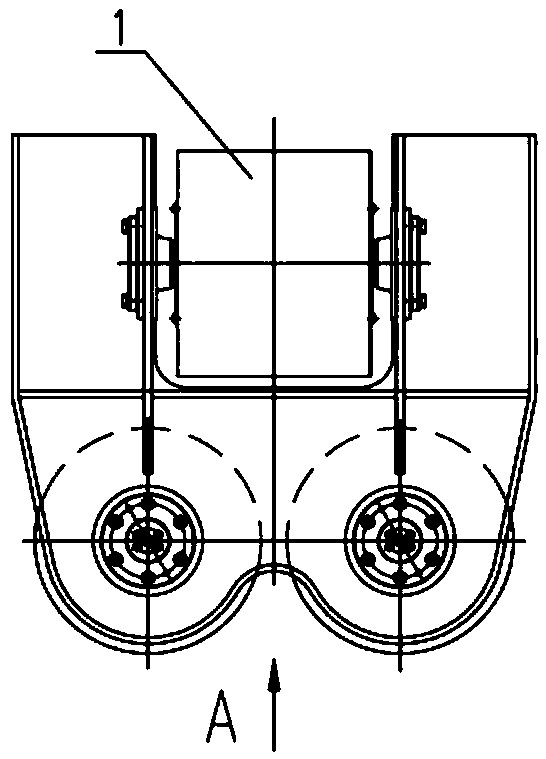

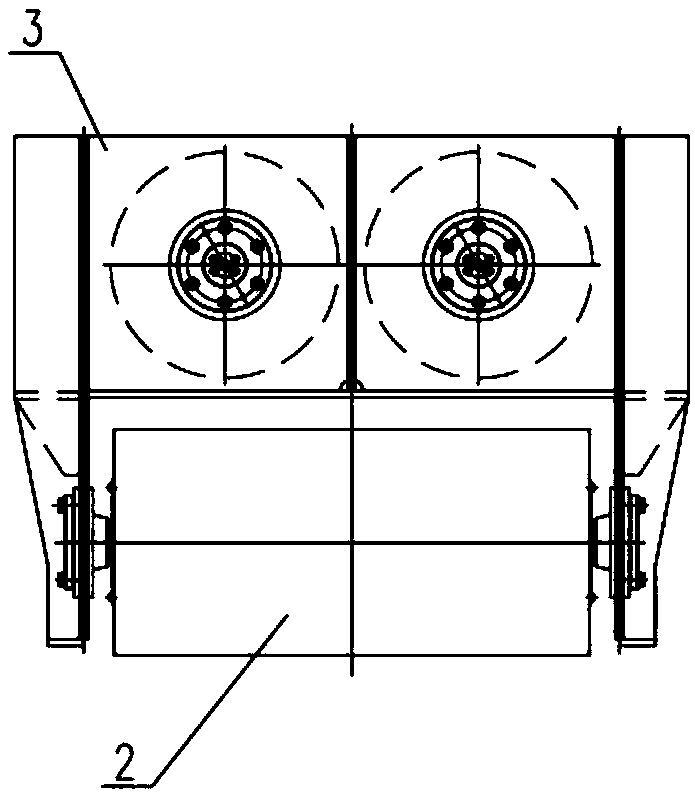

[0044] Wherein, the structure of well-tac-toe roller 102 is as Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com