A floating sealing device for pyrolysis rotary kiln

A floating seal and rotary kiln technology, applied in the field of coal chemical industry, can solve the problems of leakage between the fixed cover shell and the rotary kiln shell, and achieve the effect of remarkable sealing effect, wide application range and high degree of cooperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further explained below in conjunction with the accompanying drawings and examples, and the scope of the invention is intended to be defined, and the objectives of the invention are intended to protect all techniques in the scope of the invention.

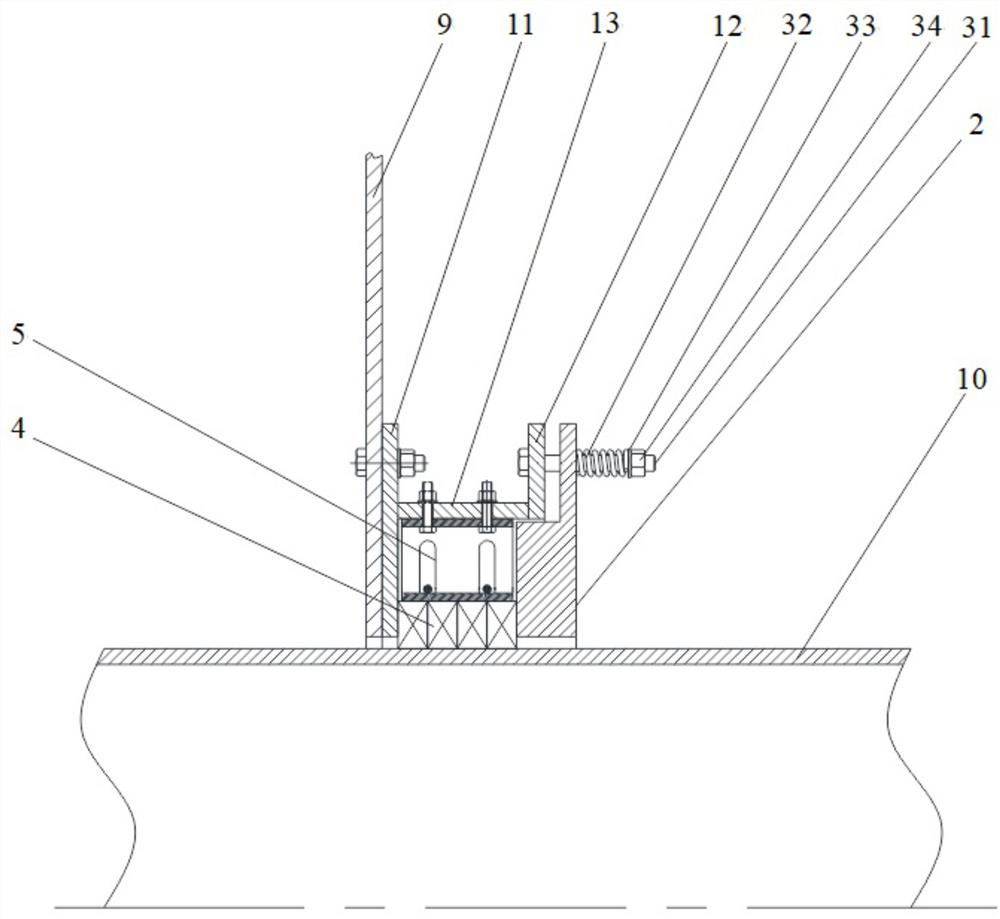

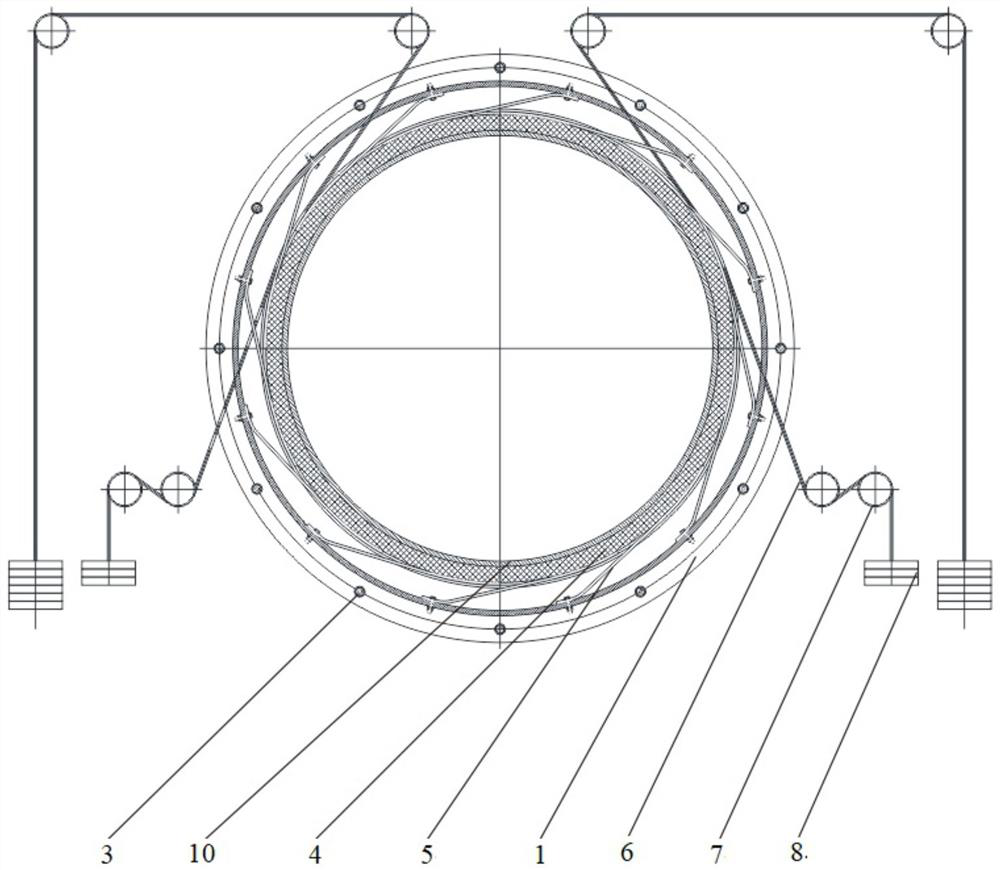

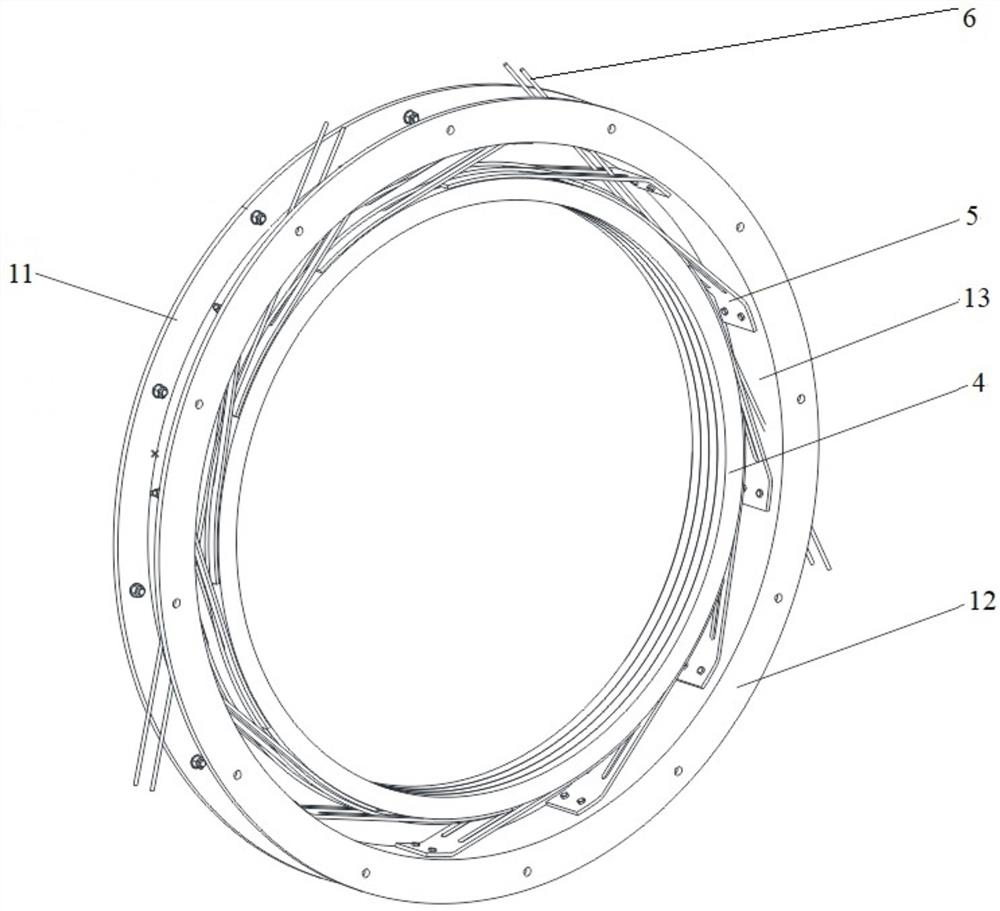

[0038] Join Figure 1-8 A pyrolysis-rotary kiln floating sealing device is provided on the outer edge of the rotary kiln cylinder 10 attached to the rotary kiln cylinder 10 and the fixed housing 9; including a sealed seat, a compression cover 2, a coil spring system 3, disk 4, several spring steel sheets 5, several bolts, several screws, several nuts, and tensioning devices.

[0039] The sealing race 1 includes an inner ring 11, an outer ring 12 and a neck ring 13 disposed between the inner ring 11 and the outer ring 12; the inner ring 11 and the outer ring 12 are annular structures disposed in parallel, inner ring 11 and outer ring 12 The outer diameter is the same, the outer ring 12 has an inner diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com