Chambering structure capable of achieving continuous bullet shooting

A continuous shooting and loading technology, applied in the field of toy guns, can solve the problems of difficulty in shooting bullets, affecting the use of toy guns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

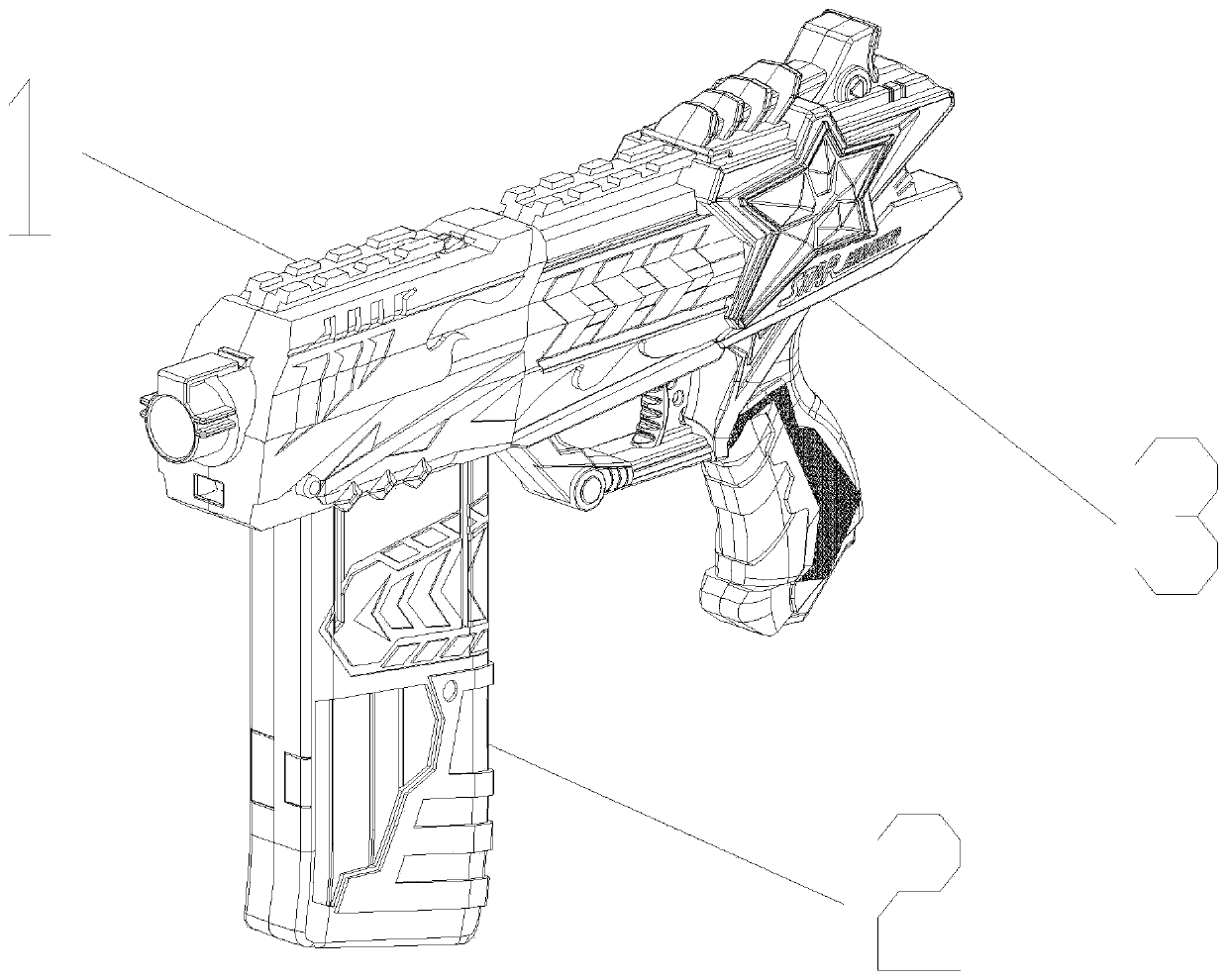

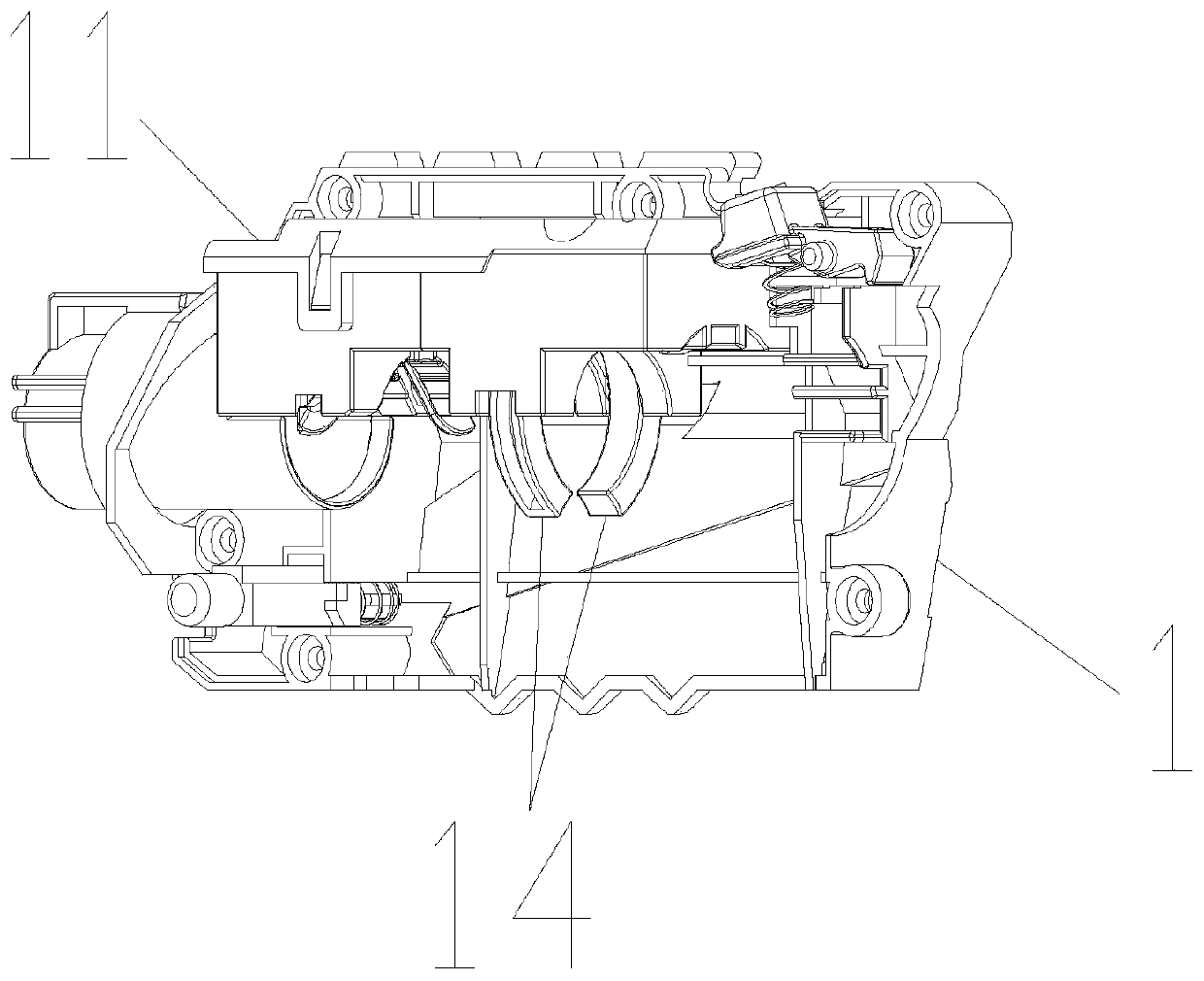

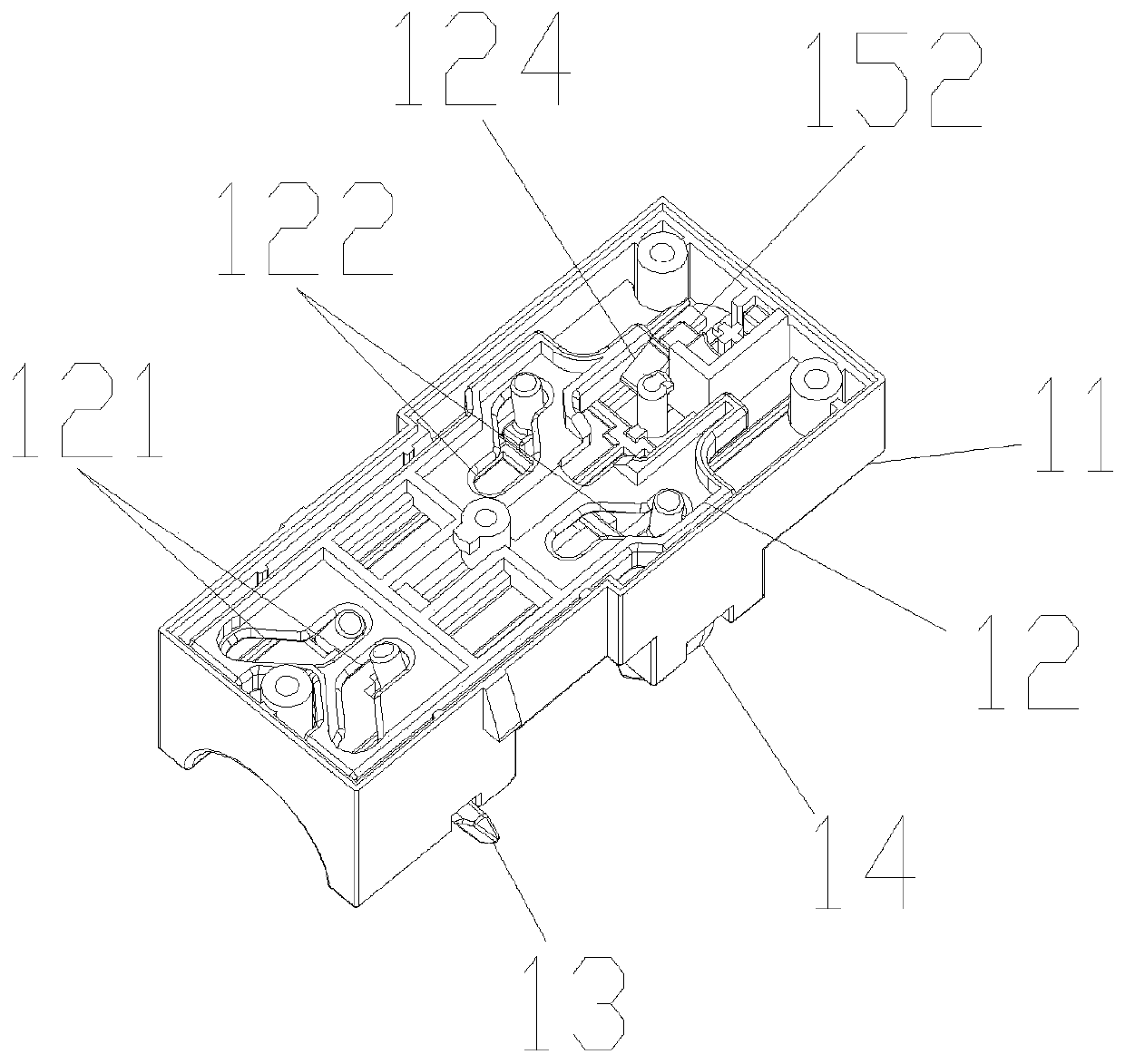

[0014] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 : a loading structure for continuous shooting of bullets of the present invention, the loading operation of the related toy gun 3 is that when the user pulls the loading pull piece to load the toy gun 3, the barrel 31 of the toy gun 3 will be pushed forward; When the user finishes loading the chamber and pulls the trigger to shoot the bullet, the barrel 31 of the toy gun 3 will retract. With the back and forth movement of the gun barrel 31 of the toy gun 3, the top button 5 and the push plate push rod 23 are pushed to drive the operation of the bullet burst structure.

[0015] The gun barrel 31 in the toy gun 3 is provided with a barrel top buckle, and when the gun barrel 31 is loaded, its gun barrel top buckle will be tightened by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com