Track board based on distributed optical fiber monitoring

A distributed optical fiber and track slab technology, applied in the field of track engineering, can solve the problems of lack of data recording, analysis and evaluation in the application of ballastless track structure in the whole life cycle, and achieve the effect of improving the ability of operation data collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a track plate based on distributed optical fiber monitoring;

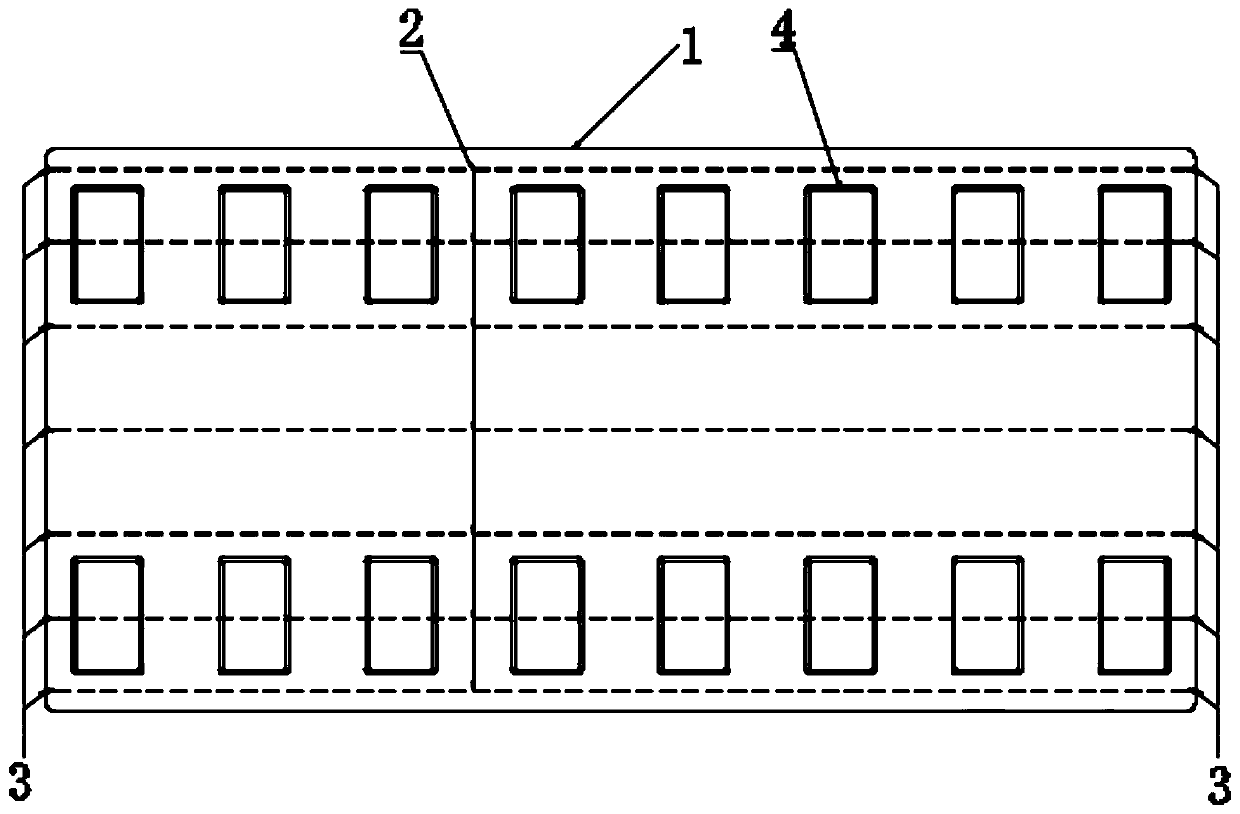

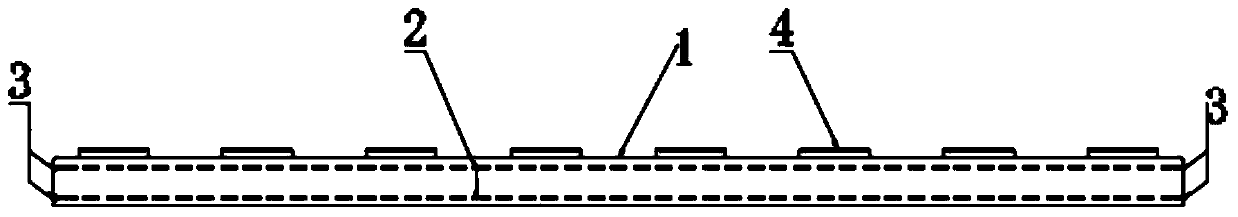

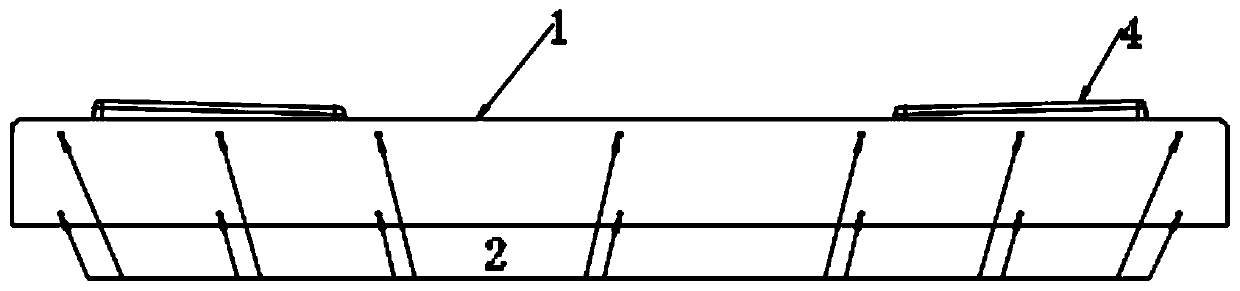

[0029] Such as Figure 1-Figure 3 As shown, in the track plate based on distributed optical fiber monitoring in this embodiment, several distributed optical fibers 2 are buried inside the track plate 1 , and optical fiber connectors 3 are provided at both ends of each distributed optical fiber 2 .

[0030] The present invention embeds several distributed optical fibers inside the track slab, and each distributed optical fiber is provided with an optical fiber connector at both ends, and is connected with a measuring device to form a measurement loop during use, which can measure the internal stress, strain, temperature and cracks of the track slab, etc. data, and by using the transmission efficiency of optical fiber, various parameters during the operation of the track slab can be collected in real time. After big data analysis, it can provide real-time monitoring of the use status o...

Embodiment 2

[0038] Such as Figure 4 As shown, a track structure includes laying several track slabs 1 described in Embodiment 1 along the line, and the distributed optical fibers 2 in adjacent track slabs 1 are correspondingly connected in series by connecting optical fibers 5, and the connecting optical fibers 5 and The optical fiber connectors 3 at the ends of the distributed optical fibers 2 are connected.

[0039] In the present invention, by correspondingly connecting the distributed optical fibers in adjacent track plates through connecting optical fibers, a closed-loop track plate distributed optical fiber monitoring circuit laid along the line can be formed, so as to monitor the internal stress, strain, temperature and temperature of the track plate in real time. Cracks and other data collection, the track structure can greatly improve the operation data collection ability of the ballastless track structure, and provide great help for the realization of railway track system infor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com