Limited torque locking strip

A locking bar and torque technology, which is applied in the direction of automatic clutches, clutches, mechanical equipment, etc., can solve the problems of loose electronic equipment, high wear on the tooth top, and the adjustable range is not very free, so as to facilitate the locking operation and loosening Effects of operation, reduction of component wear, and expansion of the upper limit setting range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

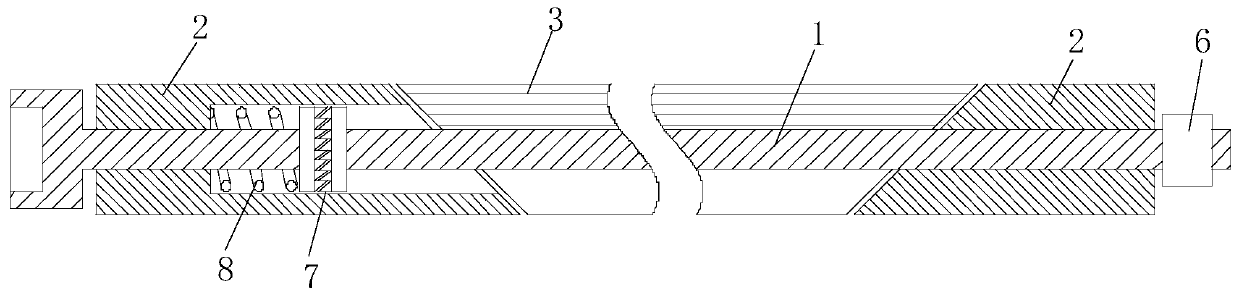

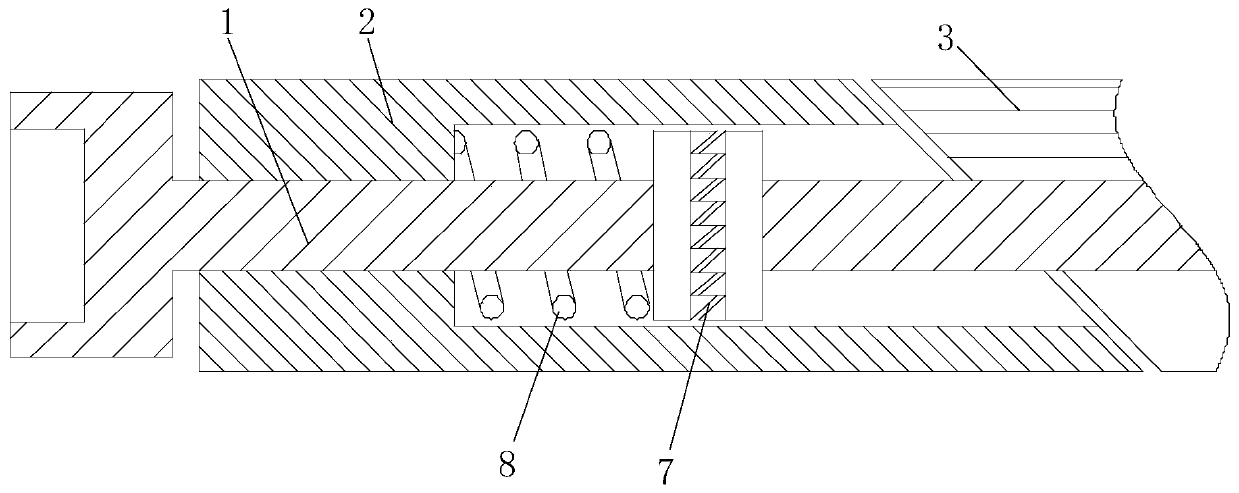

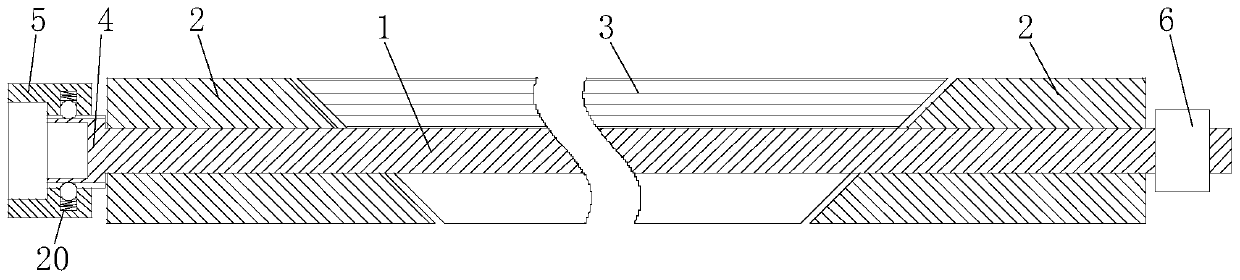

[0036] Such as Figure 3 to Figure 10 As shown, the limited torque locking bar includes an adjusting screw 1, a fixed wedge 2 and a movable wedge 3 connected in series on the adjusting screw, a limit adjusting head 4 fixedly arranged at the end of the adjusting screw and used for loosening adjustment, And the locking adjustment sleeve 5 that is placed on the outer wall of the limit adjustment head and used for locking adjustment, wherein the form and quantity of the fixed wedge, the movable wedge and the adjustment screw itself can adopt the same structure as the prior art, such as The center of the adjusting screw is a polished rod, and the end is in the form of a screw, which is not improved in this technology; generally, a nut 6 for overall fixing and adjustment is also arranged on the screw of the adjusting screw.

[0037] The outer wall of the limit adjustment head is in the shape of a circular surface, that is, the limit adjustment head is a cylindrical outer wall, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com