Short-shaft rotary self-balancing mechanism

A rotary, self-balancing technology, applied to agricultural machinery, agricultural machinery and implements, applications, etc., can solve problems such as deviation of implements, difference between operating depth of tillage and set depth of tillage, and incomplete crushing of operations, etc., to achieve changing adjustment methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

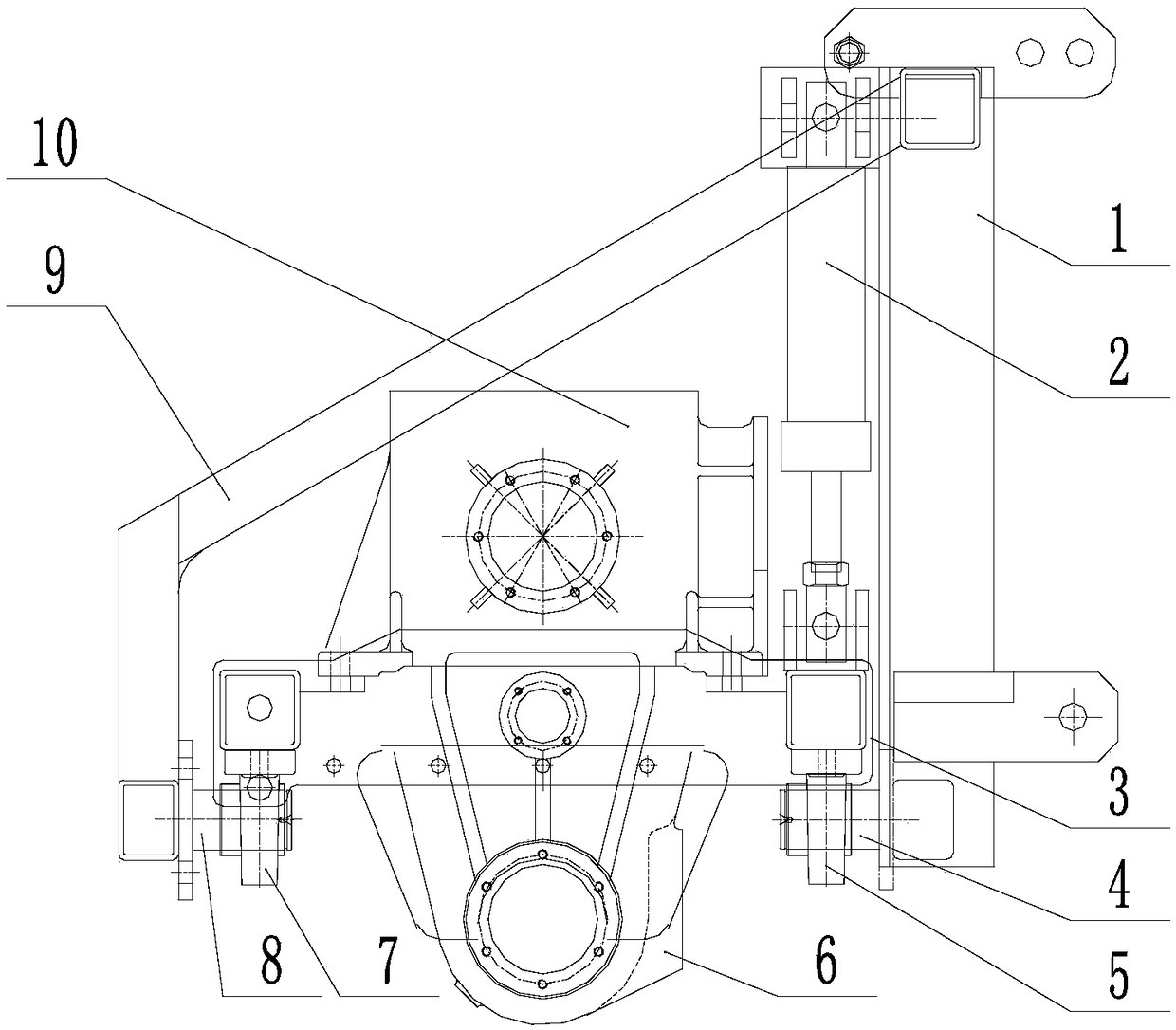

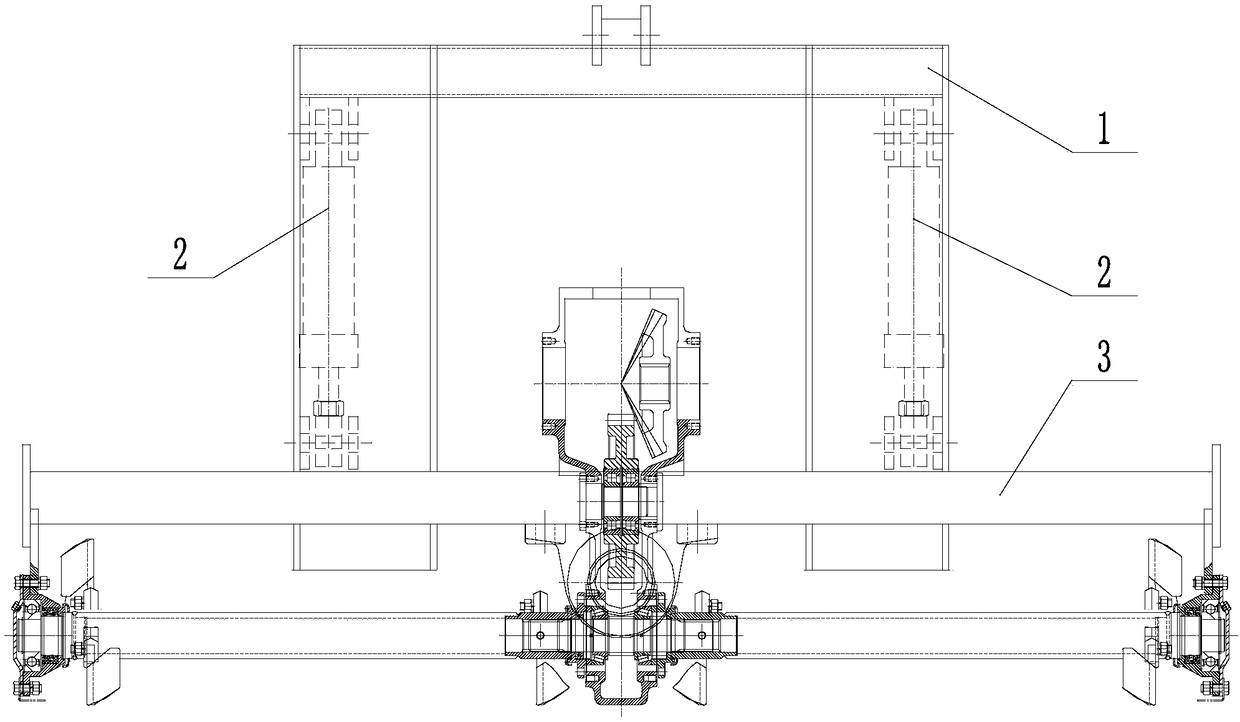

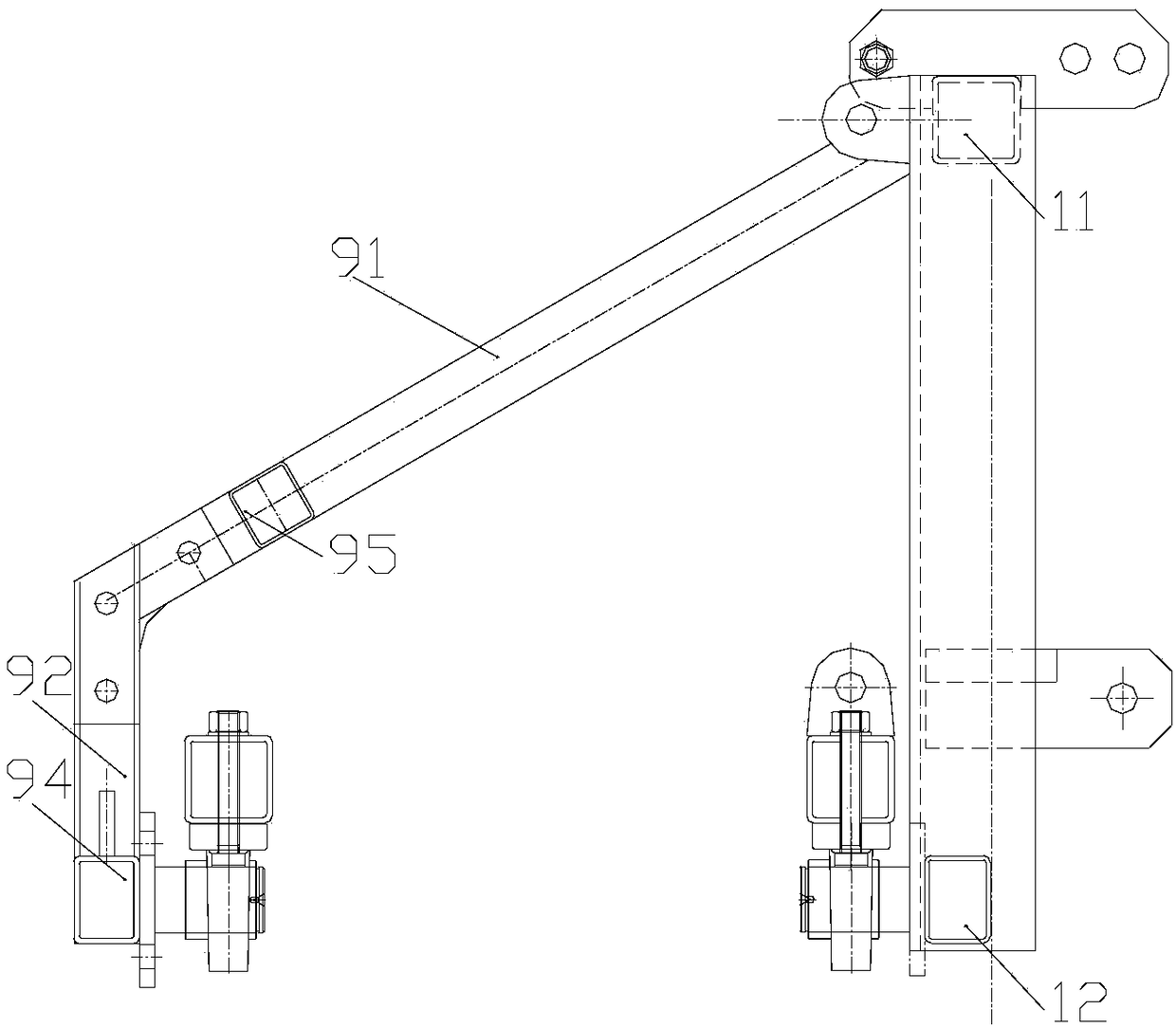

[0019] Embodiment 1: as figure 1 The short-axis rotary self-balancing mechanism shown includes a frame, and the frame includes a detachable suspension 1, a suspension beam 9 and a frame 3, the detachable suspension 1 and the frame 3 are square frames, and the detachable suspension 1 is Set vertically, the top of the suspension beam 9 is connected to the top of the separate suspension 1 to form a balance adjustment bracket, and the frame 3 is horizontally arranged between the bottom of the separate suspension 1 and the bottom of the suspension beam 9; the bottom of the separate suspension 1 is installed with a rear protruding The front beam rotation short shaft 4, the bottom of the suspension beam 9 is equipped with a forward protruding back beam rotation short shaft 8, the front beam and the rear beam of the frame 3 are connected to the front beam rotation short shaft through the front beam short shaft coupling 5 and the rear beam short shaft coupling 7 respectively. Axis 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com