An adjustment method for a flexible adjustment system for power generation load of a multi-heat source cogeneration unit

A technology of cogeneration unit and power generation load, which can be applied to heating systems, heating methods, machines/engines, etc., and can solve the problems of limited electric load adjustable range, high heating energy consumption, and difficulty in power grid peak regulation. Achieve the effect of expanding the heating capacity and solving the shortage of heat sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

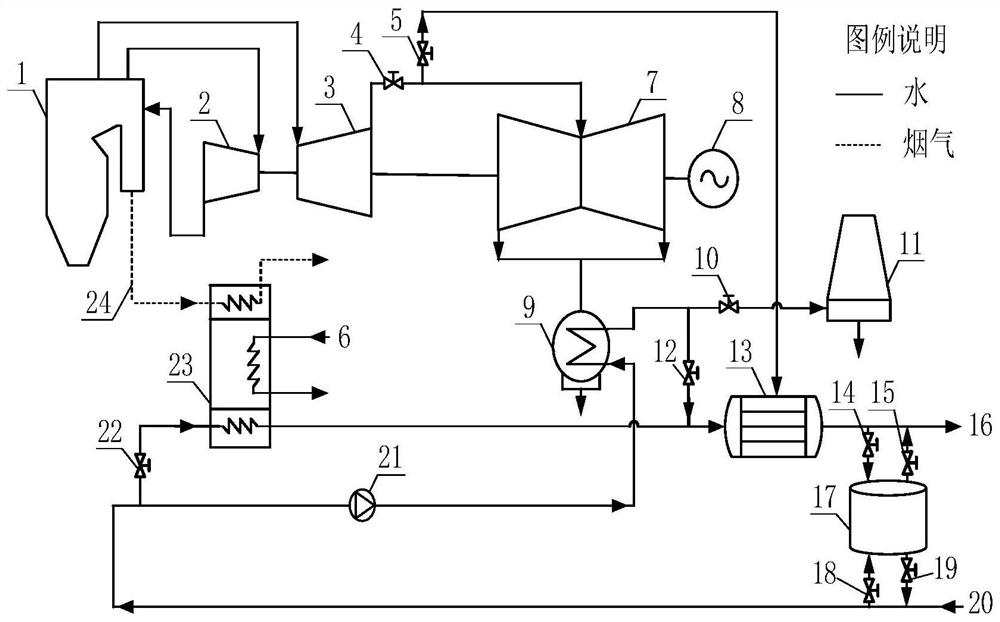

[0018] The present invention proposes a flexible power generation load adjustment system for a multi-heat source cogeneration unit. The multi-heat source heating system is composed of a conventional coal-fired power generation system and a multi-heat source cogeneration unit power generation load flexible adjustment system. The following describes this system with reference to the accompanying drawings. The invention is explained.

[0019] figure 1 Shown is the schematic diagram of the power generation regulation system of the multi-heat source cogeneration unit. The conventional coal-fired power generation system includes a boiler 1, a high-pressure cylinder 2, a medium-pressure cylinder 3, a low-pressure cylinder 7 and a generator 8 connected in series; wherein; the regulating valve 4 for the steam exhaust from the medium-pressure cylinder to the steam inlet flow of the low-pressure cylinder is connected to the low-pressure cylinder. Connection; medium pressure cylinder exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com