Control method and device for unstacking, electronic equipment and medium

A control method and storage medium technology, applied in the field of electronic equipment and media, devices, and unstacking control methods, can solve the problems of unstacking failure, height difference, etc., and achieve the goals of improving accuracy, reducing processing differences, and improving quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

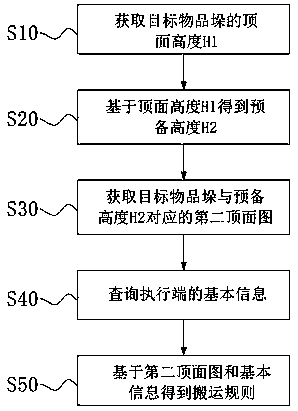

[0043] This embodiment provides a control method for unstacking, aiming at solving the problem that during the unstacking process, as the level decreases, the difference between the actual top surface height and the expected top surface height of the target item stack will gradually increase. , and even lead to the failure of unstacking. Specifically, refer to figure 1 As shown, the control method may include the following steps.

[0044] Step S10, obtaining the height H1 of the top surface of the target article stack. It is worth noting that the target item stack is formed by stacking items layer by layer, and the top surface height H1 is the height of the upper surface of the top item. In order to improve the stability of handling, the items in the target item stack should preferably be placed neatly and of the same type, and the single-layer items should be placed regularly and kept on the same layer and at the same height. During the unstacking process of the target item...

Embodiment 2

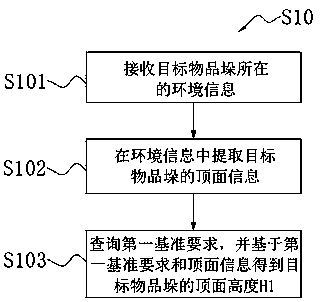

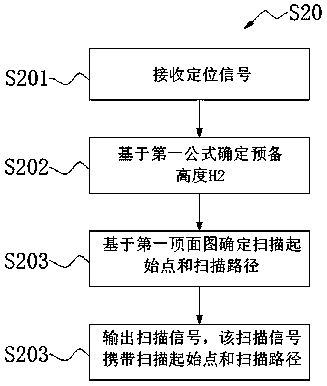

[0052] This embodiment provides a control method for unstacking, which is carried out on the basis of Embodiment 1. Specifically, refer to figure 2 As shown, step S10 includes step S101 to step S103.

[0053]Step S101, receiving environment information of a target article stack. The environmental information can be an image, and the image should include the entire stack of target items and the space in which they are located.

[0054] It can be understood that, the environment information is collected by the first camera, and the first camera may be communicatively connected with the execution device of the method. Specifically, there is a support base around the place where the target product stack is placed, and the first camera is fixed on the support base and is set facing the target commodity stack. When destacking is required, the first camera collects environmental information and uploads it to the The execution device for the method.

[0055] The first camera can ...

Embodiment 3

[0082] This embodiment provides a control device for unstacking, which is the virtual device structure of the above embodiment. It aims to solve the problem that as the level decreases during the depalletizing process, the difference between the actual top surface height and the expected top surface height of the target item stack will gradually expand, and even lead to the failure of depalletizing. refer to Figure 6 As shown, the control device may include a first acquisition module 1 , a second acquisition module 2 , a query module 3 and a processing module 4 .

[0083] Specifically, the first acquisition module 1 is used to obtain the top surface height H1 of the target article stack, and obtain the preliminary height H2 based on the top surface height H1, and the difference between the preliminary height H2 and the top surface height H1 is a constant C greater than zero; The second acquisition module 2 is used to obtain the second top view corresponding to the target ite...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap