A water-saving self-cleaning pipeline filter device

A filter device and self-cleaning technology, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of inconvenient replacement of filter elements, unfavorable water consumption for users, waste of water resources, etc., to increase water experience and increase self-cleaning ability, the effect of not wasting water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

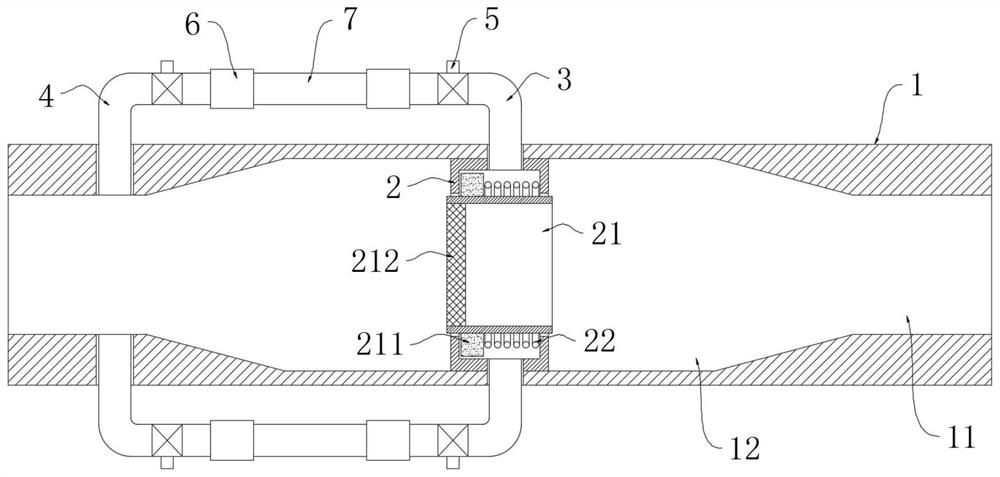

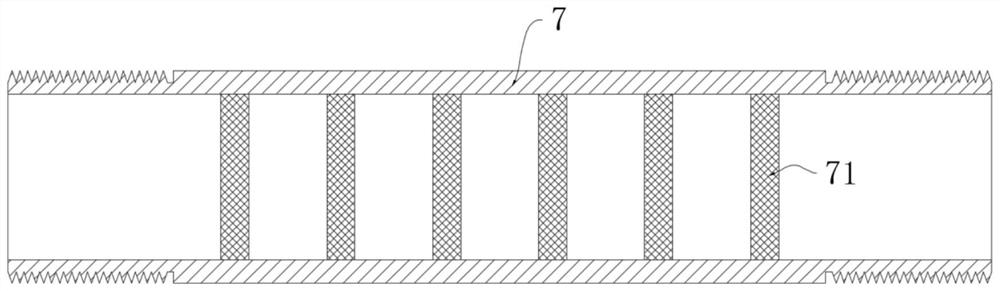

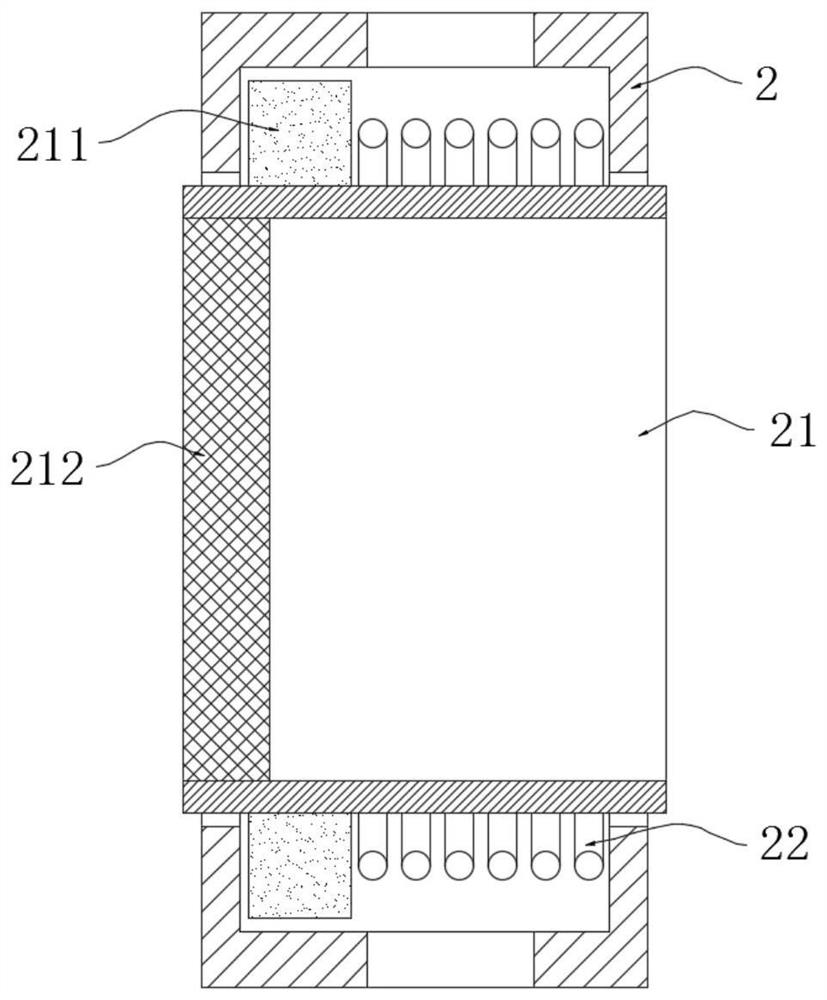

[0029] refer to Figure 1-3 , a water-saving self-cleaning pipeline filter device, including a connecting pipe 1, the connecting pipe 1 includes a connecting nozzle 11 and a lumen 12, a piston sleeve 2 is installed in the lumen 12, and the piston sleeve 2 is a cavity structure, A filter tube 21 is slidably inserted on the piston sleeve 2, and a retaining ring 211 is installed on the outer wall of the filter tube 21. A spring 22 is installed between the retaining ring 211 and the inner wall of the piston sleeve 2, and the outer wall of the connecting pipe 1 A plurality of first right-angle pipes 3 and a plurality of second right-angle pipes 4 are respectively sealed and inserted, and the opposite ends of each first right-angle pipe 3 and the second right-angle pipe 4 are equipped with threaded connection sleeves 6, and the two threaded connection sleeves A filter core tube 7 is installed between the 6, the end of the first right-angle tube 3 away from the threaded connection sl...

Embodiment 2

[0040] refer to Figure 4 , a water-saving self-cleaning pipeline filter device, which is basically consistent with Embodiment 1, the difference is that:

[0041] The side wall of the piston sleeve 2 extends and is equipped with a plurality of support frames 23, and a gillnet board 231 is installed on the plurality of support frames 23, and the gillnet board 231 is located in the filter pipe 21;

[0042] After the filter screen 212 is clogged and pushed by the water flow to move into the piston sleeve 2, the filter screen 212 is pierced by the gill mesh plate 231 placed in the filter tube 21, and the impurities on the filter screen 212 are quickly cleaned, and the cleaned impurities are removed. The water flow is brought into the filter core tube 7 to filter, so that the device can increase the speed of cleaning the filter screen impurities and the degree of cleaning impurities is higher, which further increases the self-cleaning ability of the device.

[0043] In this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com