A closed weighing and feeding device and its application method

A feeding device and a closed technology, which is applied in the field of closed weighing and feeding devices, can solve the problems of dust entry, pollution, and low conveying efficiency, and achieve the effect of improving efficiency and achieving airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

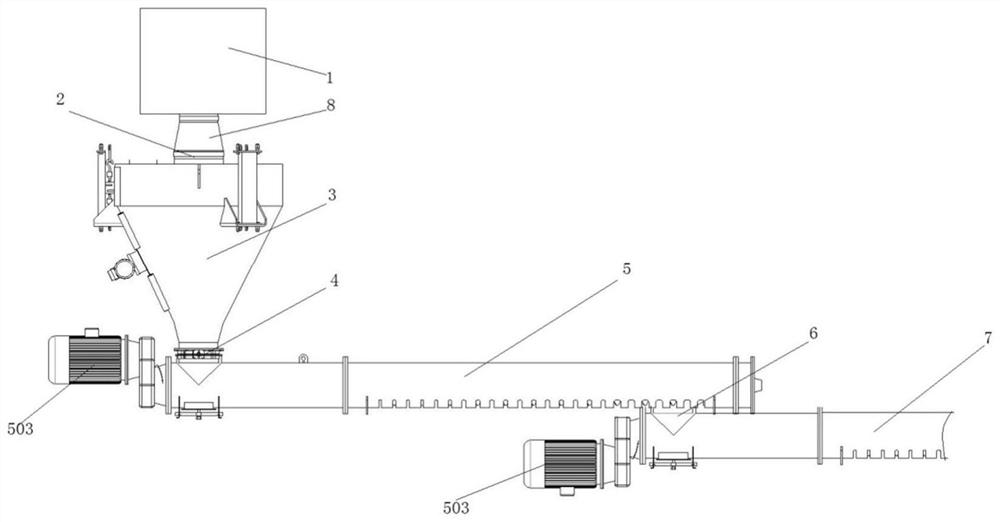

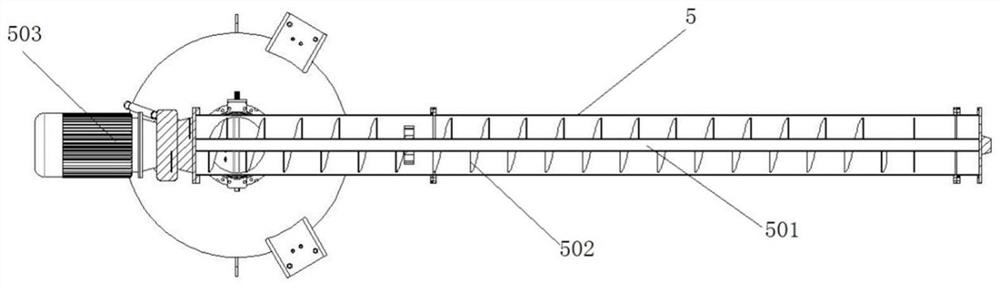

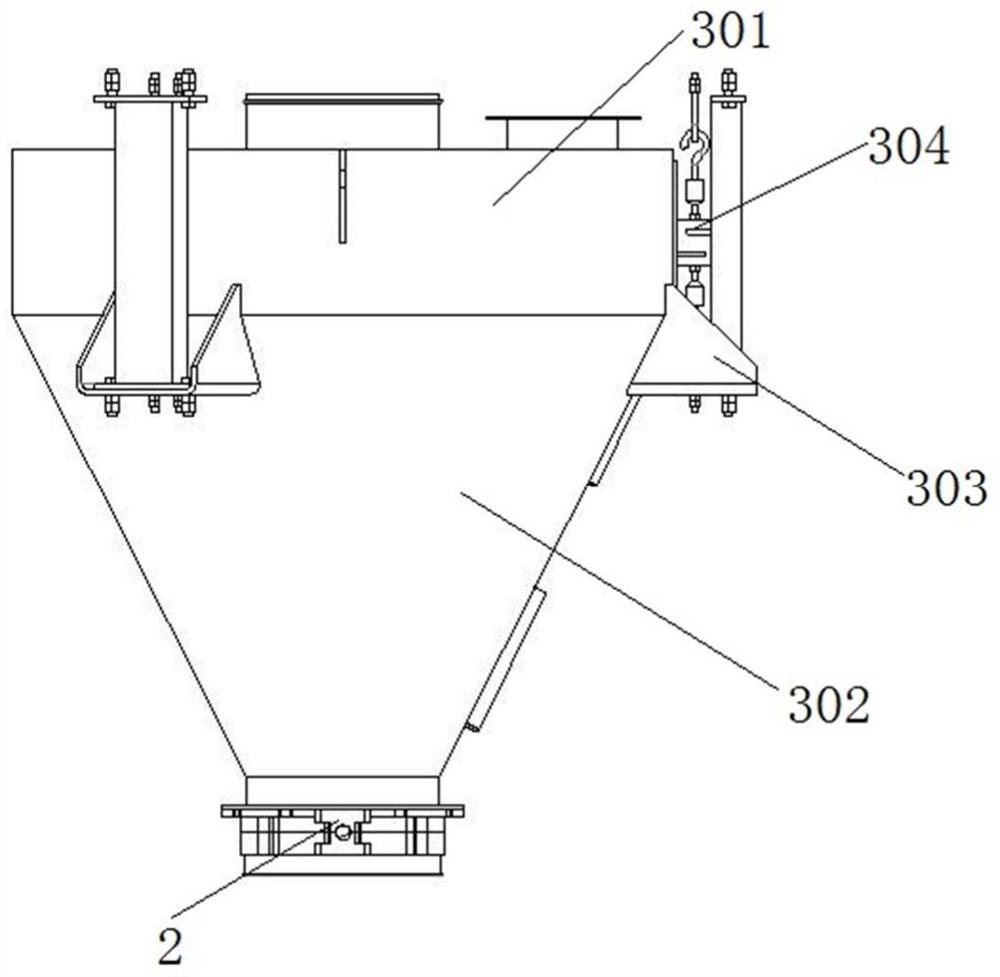

[0050] like figure 1 As shown, a closed-type weighing and feeding device includes, from top to bottom, a feed bin 1 , a weighing bin 3 , a first delivery pipeline 5 and a second delivery pipeline 7 . A first valve 2 is provided between the silo 1 and the weighing silo 3 , and the first valve 2 is used to control the discharge of materials in the silo 1 . A second valve 4 is provided between the weighing bin 3 and the first conveying pipeline 5 , and the second valve is used to control the discharge of materials in the weighing bin 3 . A third valve 6 is provided between the first delivery pipeline 5 and the second delivery pipeline 7 , and the third valve 6 is used to control the discharge of the material in the first delivery pipeline 5 .

[0051] The first valve 2 is used to connect the silo 1 and the weighing silo 3 to ensure the tightness between the silo 1 and the weighing silo 3, and the third valve 6 is used to connect the first conveying pipeline 5 and the second The...

Embodiment 2

[0064] In Example 1, it is not difficult to see that after the material is weighed, the first-level transmission and the second-level transmission are realized, and in order to realize the complementary interference between the first-level transmission and the second-level transmission, the second valve 4 and the third The valve 6 realizes mutual restriction. However, the existing valves will cause material loss when discharging, that is, some materials remain on the valve, especially the weighed powder, which will reduce the weight of the transported materials and cause large errors.

[0065] For this reason, the inventor has designed a kind of valve that does not affect the material weight that matches with it. Firstly, the structures of the first valve 2, the second valve 4 and the third valve 6 are the same. Here, the first valve 2 is taken as an example, such as Figures 4 to 5 shown. Said one valve comprises: a valve body 201, a triangular blade 202 equidistantly hing...

Embodiment 3

[0071] In Embodiment 1 and Embodiment 2, the improvement of sealing and valves has realized the transportation of the material after weighing and ensuring no loss of quality, but if the general material is placed in the bin 1 for too long, or if it is wet It is a reunion, which will also affect the weighing of the weighing chamber 3.

[0072] Because if the weighing bin 3 directly weighs the wet material, then in the process of transmission, because the work of the conveying components causes the airflow inside the conveying pipeline to generate, and the wet material will volatilize, the actual material weight and weighing The quality obtained in bin 3 is different, and when the wet material passes through the conveying pipeline, it will also bond, so that the material cannot be completely conveyed, and the weight will deviate again.

[0073] Therefore, the inventor wants to pretreat the material by breaking up and drying before weighing, so as to avoid errors caused by humidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com