A process and device for upgrading waste oil by boiling coal

A technology for improving the quality of waste oil and coal, which is applied to the recovery of fat oil/fatty acid from waste materials, the petroleum industry, and the recovery of fatty substances. It can solve the problems of unfavorable long-distance transportation and storage, high transportation cost per unit energy, and high moisture content. Achieve good environmental protection effect, increase high-value utilization value, and increase calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

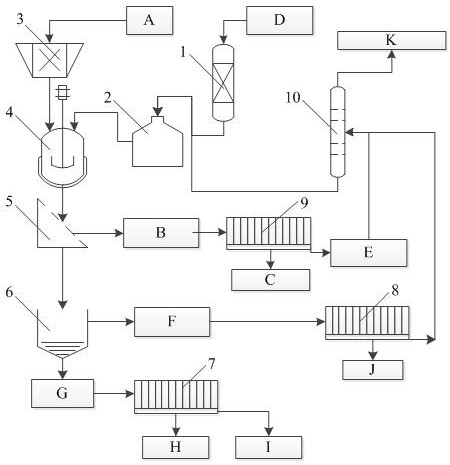

[0032] Such as figure 1 As shown, a set of treatment equipment for waste oil cooking and upgrading coal includes impurity removal purifier 1, oil storage tank 2, crusher 3, waste oil cooking kettle 4, filter screen 5, oil-water separation and settling tank 6, filter press machine and fractionation tower 10;

[0033] The impurity removal purifier 1 is connected with the oil storage tank 2, and the oil storage tank 2 is connected with the waste oil coal cooking kettle 4; the crusher 3 is connected with the waste oil coal cooking kettle 4, and the bottom of the waste oil coal cooking kettle 4 is connected with the filter screen 5 to filter The solid outlet of the sieve 5 is connected to the third filter press 9, the liquid outlet of the filter sieve 5 is connected to the oil-water separation settling tank 6, the upper outlet of the oil-water separation settling tank 6 is connected to the second filter press 8, and the bottom outlet is connected to the first filter press 7. The g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com