Coking process and device

A technology of a process and a pretreatment device, which is applied in the fields of waste oil utilization and coal processing, can solve the problems of high-value utilization, etc., and achieve the effects of improving the shortage situation, being beneficial to environmental protection, and having a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

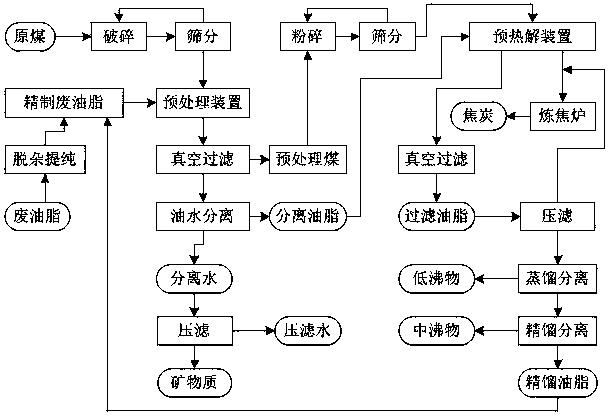

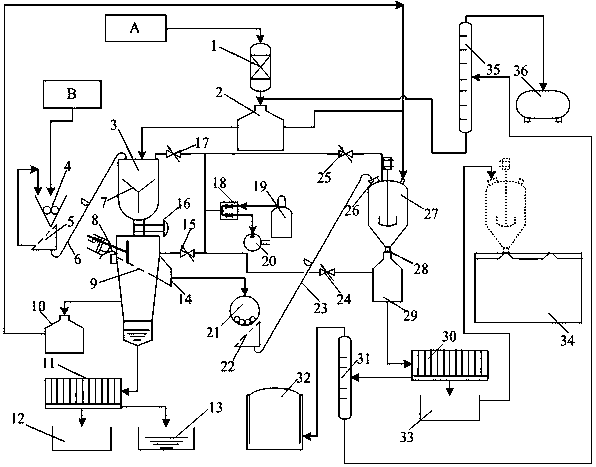

[0035] like figure 1 and 2 As shown, a coking device includes a de-impurity purification tower 1, a grease storage tank 2, and a preprocessor 3 connected in sequence, and a crusher 4 is sequentially connected with a first classifying screen 5, a first hoist 6, and a first hoist 6 Connect the preprocessor 3, the preprocessor 3 has the mixer 7, the discharge valve 16, the discharge port 14, the first filter screen 9, the first coal pusher 8, the discharge port 14 is connected to the pulverizer 21, and the preprocessor The bottom of 3 is connected to the first filter press 11, and the side is connected to the grease middle tank 10. The top of the preprocessor 3 and the lower side of the filter screen are connected to a first control valve 15, and the first control valve 15 is connected to a converter 18. The converter 18 is respectively connected to the inert gas bottle 19 and the vacuum pump 20; the mineral storage tank 12 is placed at the bottom of the first filter press 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com