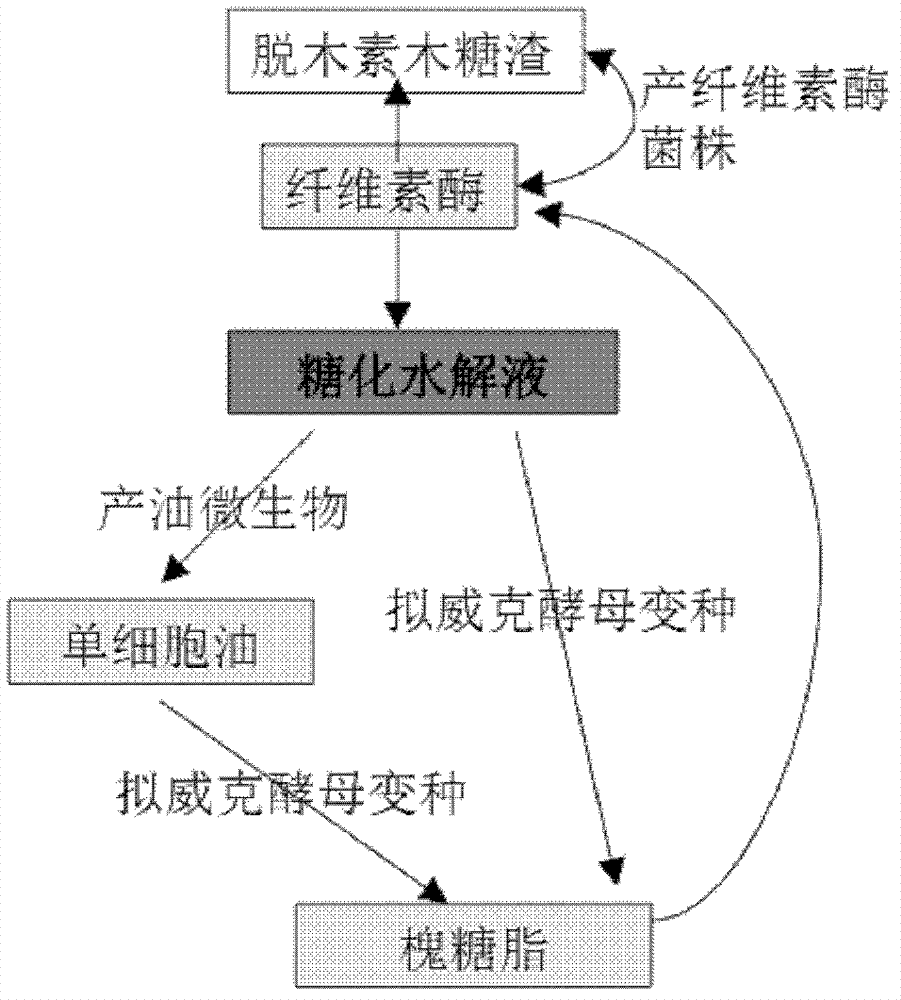

Method for producing sophorolipid through fermentation of lignocellulose material

A technology of lignocellulose and microbial fermentation biosurfactant, which is applied in the field of using lignocellulose material to ferment and produce microbial fermentation biosurfactant by using a Wick yeast variant, and achieves the effects of low price, simple process and reduced production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of cellulase solution: inoculate Penicillium decumbens JU-A10 in a regular amount in the enzyme-producing medium, shake culture at 250 rpm at 30°C for 96 h to produce enzyme, centrifuge at 6000 rpm for 30 min, and collect The supernatant is the cellulase crude enzyme solution;

[0028] The formula of the above-mentioned enzyme production medium is: 20g / l xylose residue, 30g / l bran, 6g / l microcrystalline cellulose, 5g / l bean cake powder, 2g / l ammonium sulfate, 1g / l urea, 2g / l nitric acid Sodium, 3g / l potassium dihydrogen phosphate, 0.5g / l magnesium sulfate, 3ml / l Tween 80;

[0029] (2) Preparation of saccharification solution: take delignified xylose residue, add cellulase solution with 25 FPA per gram of dry substrate, and saccharify at 45°C for 72 hours; collect the saccharification solution and put the residual cellulose in a water bath at 80°C for 30 minutes. Inactivate the enzyme, then centrifuge the saccharification solution at 8000 rpm for 10 minu...

Embodiment 2

[0036] (1) Preparation of cellulase solution: Inoculate Penicillium decumbens in an enzyme-producing medium in a conventional amount, culture at 30°C and shake at 250rpm for 84h to produce enzyme, centrifuge at 6000rpm for 30min, and collect the supernatant as cellulose Enzyme crude enzyme solution;

[0037] The formula of the above-mentioned enzyme production medium is: 20g / l xylose residue, 30g / l bran, 6g / l microcrystalline cellulose, 5g / l bean cake powder, 2g / l ammonium sulfate, 1g / l urea, 2g / l nitric acid Sodium, 3g / l potassium dihydrogen phosphate, 0.5g / l magnesium sulfate, 3ml / l Tween 80;

[0038] (2) Preparation of saccharification solution: take delignified xylose residue, add cellulase solution with 30 FPA per gram of dry substrate, and saccharify at 45°C for 72 hours; collect the saccharification solution and place it in a water bath at 80°C for 30 minutes to remove residual cellulose Inactivate the enzyme, then centrifuge the saccharification solution at 9000 rpm f...

Embodiment 3

[0045] (1) Preparation of saccharification solution: take delignified xylose residue, add commercial cellulase solution (from Qingdao Kangdien Biotechnology Co., Ltd.) with 25 FPA per gram of dry substrate, and the buffer system is pH4.8 The 0.05M HAC-NaAc buffer solution was saccharified at 45°C for 72 hours; the saccharification solution was collected and placed in a water bath at 80°C for 30 minutes to inactivate residual cellulase, and then the saccharification solution was centrifuged at 8000rpm for 10 minutes to obtain a clear saccharification solution;

[0046] (2) Detoxification treatment of the saccharified liquid: heating the saccharified liquid in a water bath to 80° C., adding 1.0% activated carbon by mass percentage, stirring for 30 minutes, and then vacuum filtering to remove the activated carbon to obtain a detoxified saccharified liquid;

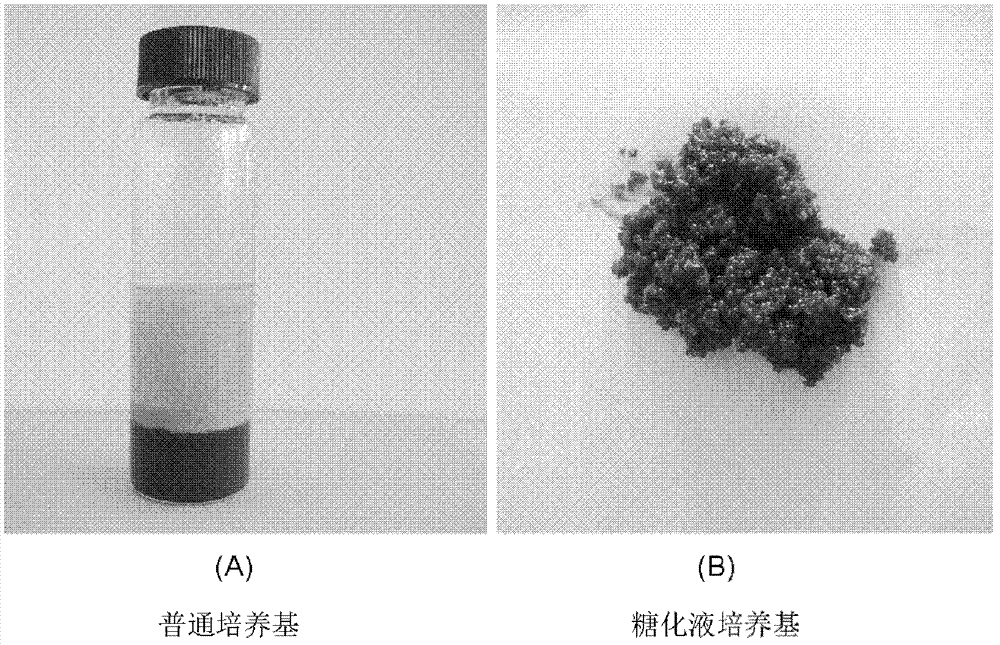

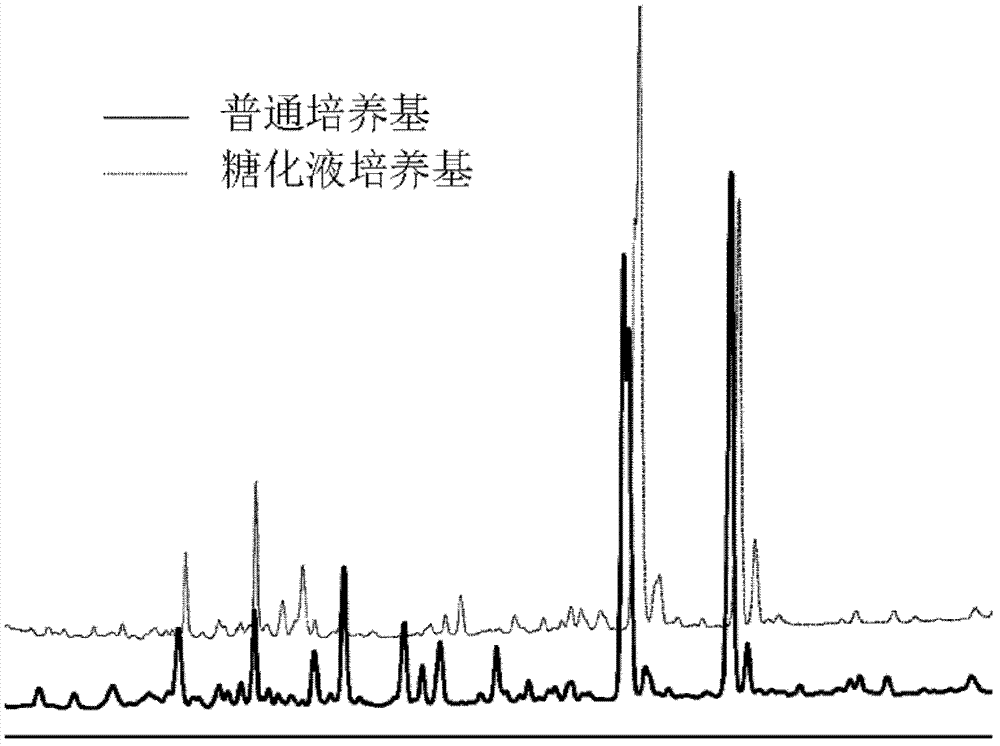

[0047] (3) Preparation of single-cell oil from saccharified liquid: prepare oil-producing saccharified liquid fermentation m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com