A device for cooking coal with waste oil and its application method

A technology of waste oil and oil, which is applied in the field of waste oil utilization technology and coal processing, can solve the problems of unfavorable long-distance transportation and storage, high transportation cost per unit energy, high moisture content, etc., achieve simple and convenient operation, increase calorific value, temperature The effect of conditional optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is further illustrated by the following examples, but not limited to the following examples.

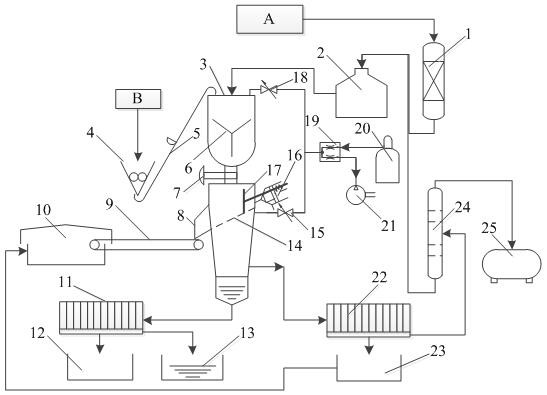

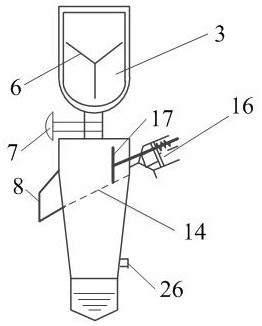

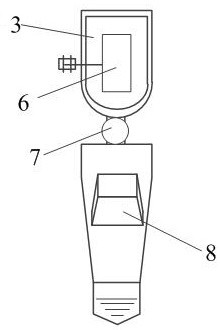

[0036] Such as figure 1 As shown, the present invention provides a device for cooking waste oil and fat, comprising a de-impurity purification tower 1, an oil storage tank 2 and a waste oil coal boiler 3 connected in sequence, and the crusher is connected to a hoist and then connected to the waste oil coal boiler 3. The waste oil coal cooker 3 has a mixer 6, a discharge valve 7, a solid discharge port 8, a filter screen 14, a coal pusher 16, a solid discharge port 8 connected to a conveyor belt 9, and the bottom of the waste oil coal cooker 3 Connected to the first filter press 11, the side is connected to the second filter press 22, the top of the waste oil coal boiler 3 and the lower side of the filter screen 14 are respectively connected with the second control valve 18 and the first control valve 15, two The control valve is connected to the converte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com