Multifunctional valve assembly structure

A valve component and multi-functional technology, applied in the direction of functional valve types, valve details, diaphragm valves, etc., can solve problems such as troublesome after-sales maintenance, waste of social resources, complex structure, etc., to improve the stability of use and service life, and save manpower And the effect of simple structure of material and valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

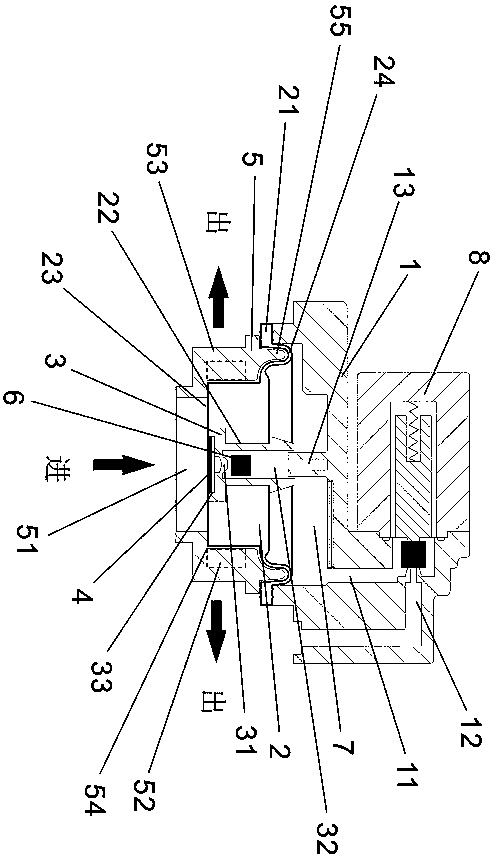

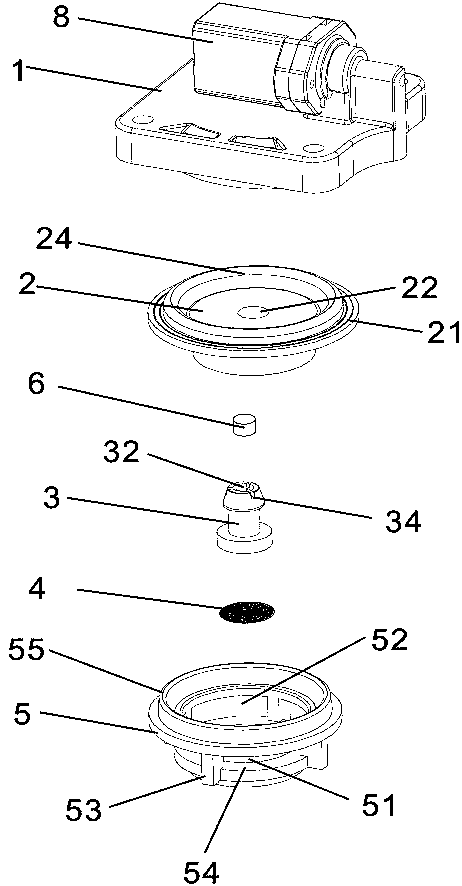

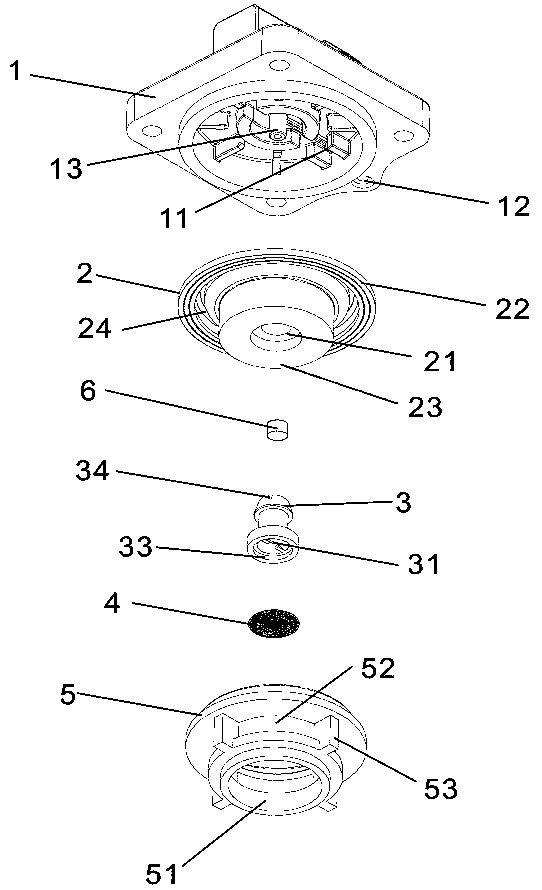

[0034] refer to Figure 1-3 , the specific embodiment adopts the following technical solutions: a multifunctional valve assembly structure, including a diaphragm cover 1, a diaphragm 2, a pilot assembly 3, a valve core filter device 4, a diaphragm protection bracket 5, a check device 6, a pressure The balance chamber 7 and the pressure relief control assembly 8, the diaphragm cover 1 is provided with a diaphragm cover pressure relief diversion hole 11, the diaphragm cover pressure relief diversion hole 11 and the matching pressure relief control assembly 8 The inlet gas or liquid inlet is connected, the pressure relief hole 12 of the pressure relief control assembly 8 is connected with the outlet 52 of the diaphragm protection bracket 5; the diaphra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com