Movable anti-bubble energy-saving building wall prefabricated part

A technology of building walls and prefabricated components, which is applied in the direction of building components, building structures, buildings, etc., and can solve problems such as the inability to splicing blocks to be firmly fixed, unable to move and adjust positions, and unable to

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

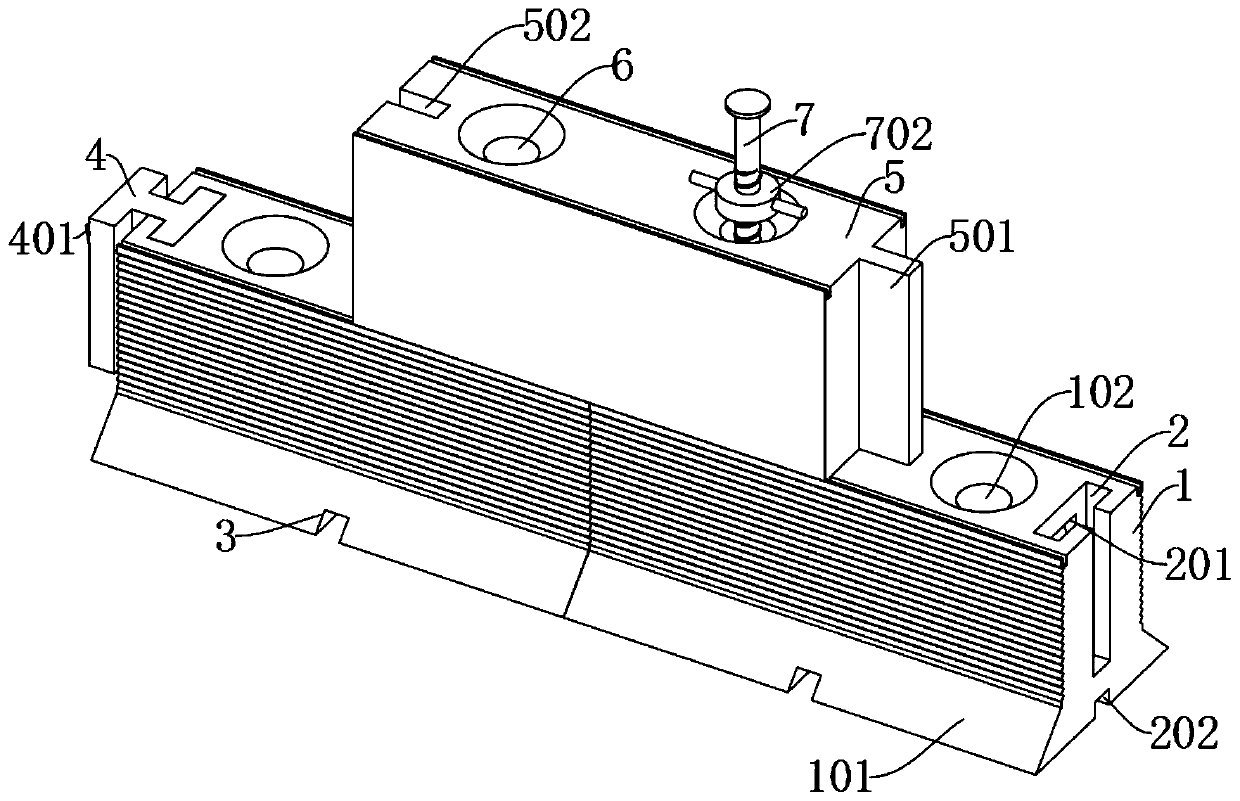

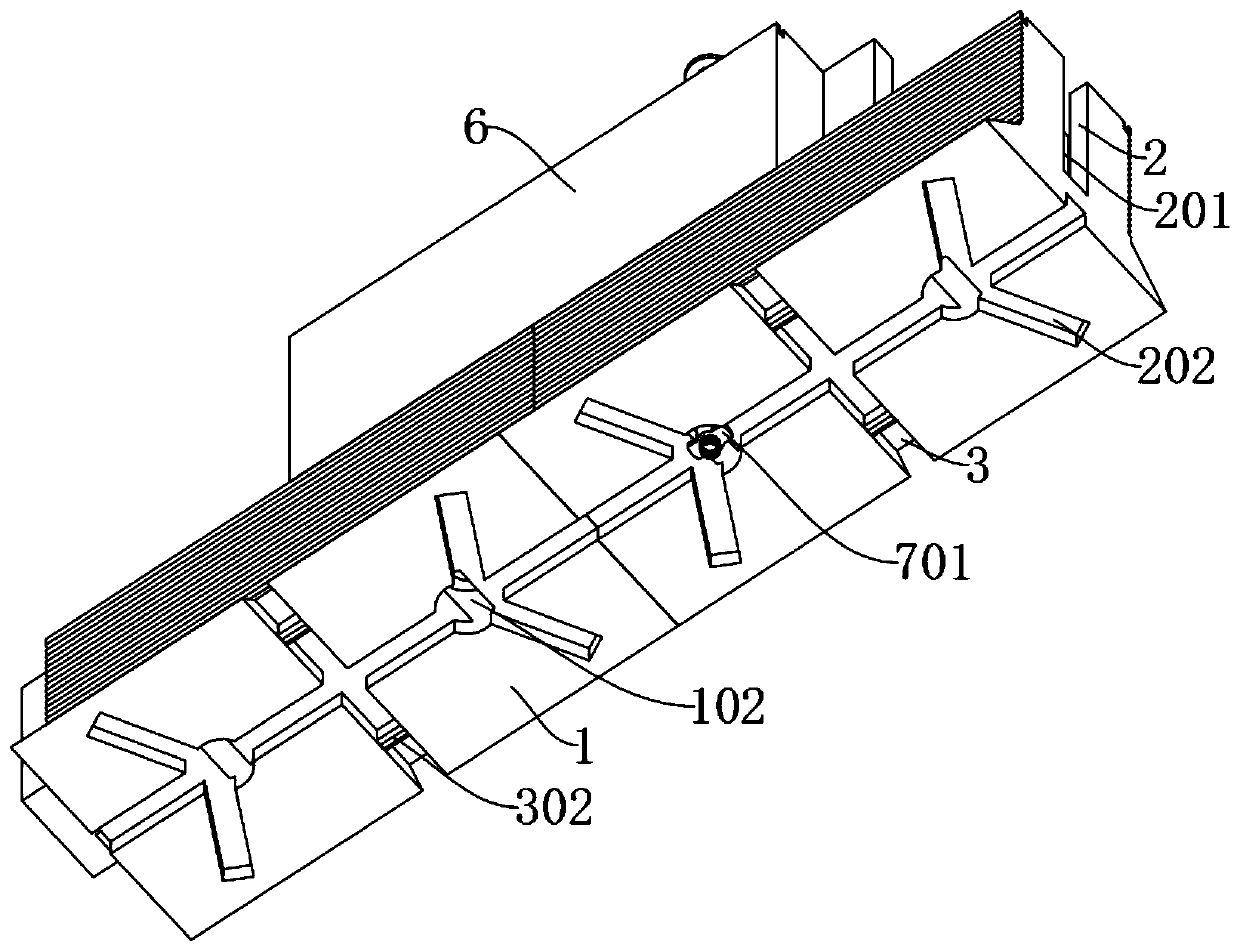

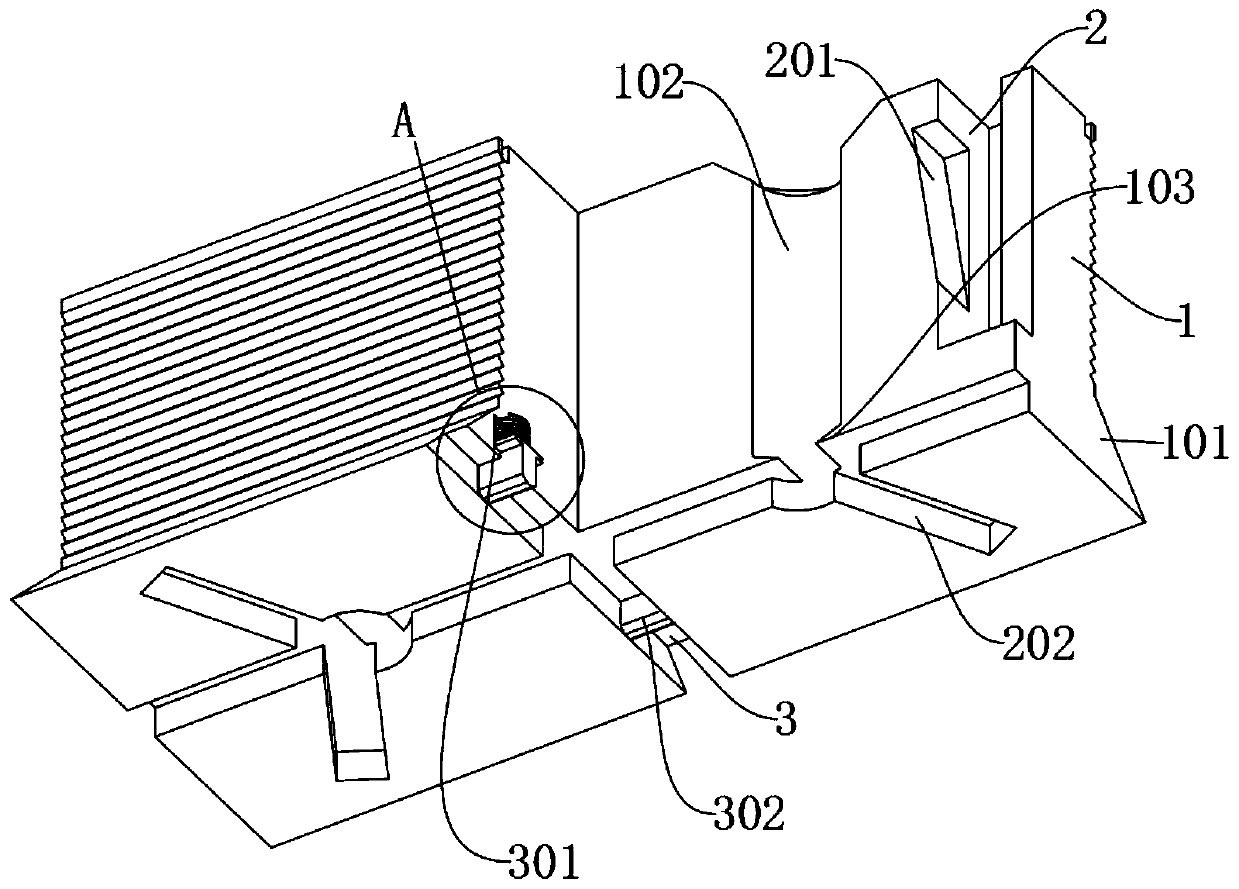

[0031] as attached figure 1 to attach Figure 9 Shown:

[0032]The invention provides a movable anti-bubble energy-saving building wall prefabricated component, which includes: a main body 1, a connecting groove 2, a slot 3, a connecting piece 4, a top piece 5, a connecting hole 6 and a connecting rod 7; the main body 1 It is a rectangular structure, and the outside of the main body 1 is provided with several wedge-shaped grooves, and the socket 102 is used to insert the insertion rod 503, so that the top piece 5 can be connected with the main body 1 through the insertion rod 503, and the stopper 103 It is used to connect with the bottom of the block 701, so that after the initial splicing, the device can be temporarily fixed by the connecting rod 7 when pouring concrete, so as to facilitate the adjustment of the moving position; the connecting groove 2 includes a limit groove 201, bottom groove 202; the connecting groove 2 is a T-shaped structure, and the inner middle posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com