A control system for fully mechanized mining face in coal mine

A technology for fully mechanized mining face and coal mine, applied in the field of control systems, can solve the problems of non-interlocking of working face equipment and trough belt conveyors, affecting the stable production of the control system of the fully mechanized mining face, and achieve the effect of interlocking and stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

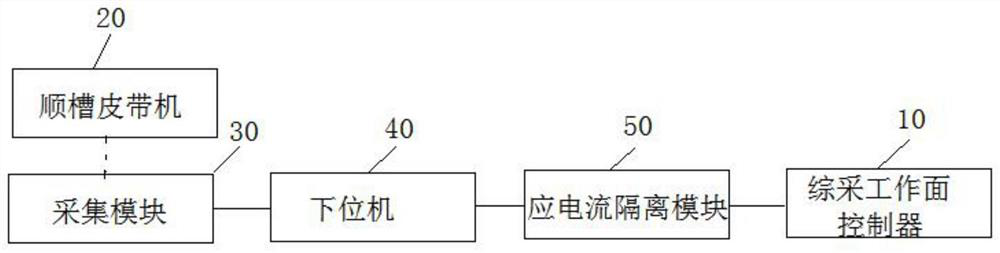

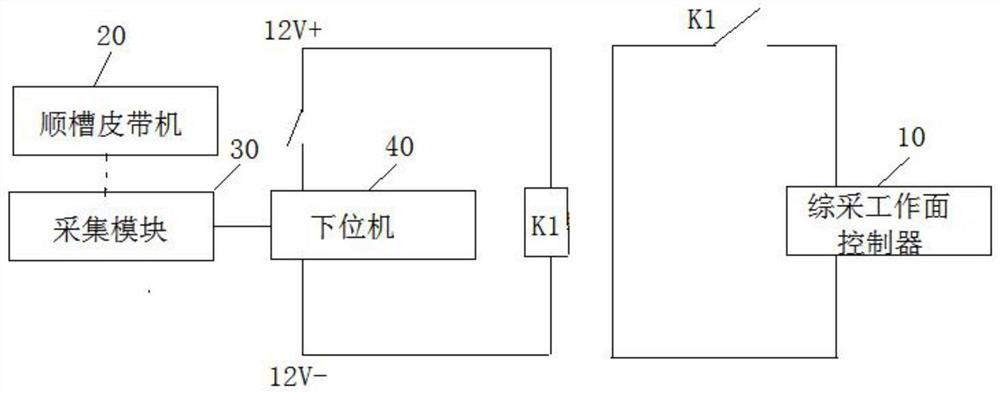

[0025] Various exemplary embodiments, features, and aspects of the embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The same reference numerals in the drawings represent the same or similar elements. Although various aspects of the embodiments are shown in the drawings, the drawings are not required unless otherwise indicated.

[0026] The word "exemplary" dedicated to "used as examples, embodiments or illustrative" herein. Any embodiment as described herein as "exemplary" does not have to be construed as better or better than other embodiments.

[0027] Further, in order to better illustrate the embodiments of the present invention, numerous specific details are given in the specific embodiments below. Those skilled in the art will appreciate that there is no specific details, and the embodiments of the present invention can also be implemented. In other examples, the methods, components, and circuits are not desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com