Double-axis three-section synchronous sliding rail

A slide rail and axis technology, applied in the field of exhibition equipment manufacturing, can solve the problems of difficult synchronization of slide rail opening and easy jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The dual-axis three-section synchronous slide rail of the present invention can be made of the following materials, and is not limited to the following materials, such as: stainless steel, profiles, aluminum alloys, plastics, pulleys, gears, bar teeth, bearings, steel profiles, etc.

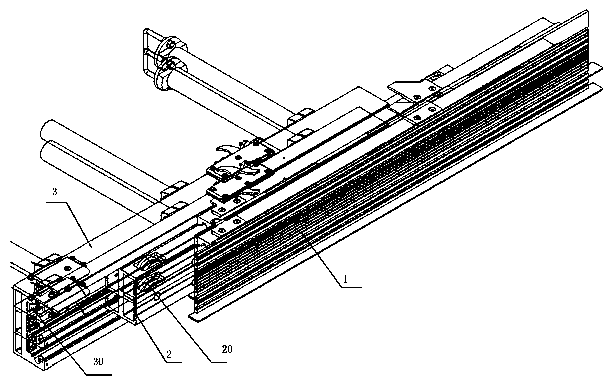

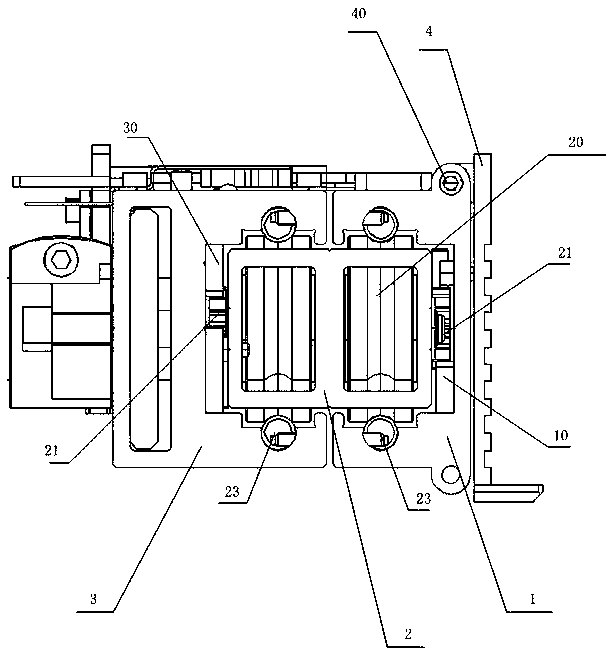

[0018] Such as figure 1 Shown is a schematic structural view of a dual-axis three-section synchronous slide rail in an embodiment of the present invention, combined with figure 2 ; The embodiment of the present invention is mainly used for the parallel push type synchronous opening operation of the museum showcase cabinet door.

[0019] The dual-axis three-section synchronous slide rail in the embodiment of the present invention includes: an outer slide rail 1, an inner slide rail 3 and an intermediate slide rail 2; the outer slide rail 1 is connected with the inner slide rail 3 through the intermediate slide rail 2 to form a three-section slide rail Rail structure, and sliding connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com