A light fixture

A clip-type, light-weight technology, applied in the direction of lifting devices, etc., can solve the problems of large required flow, high working pressure, and small carrying capacity of the whole machine, and achieve the effect of reducing the overall weight and improving synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

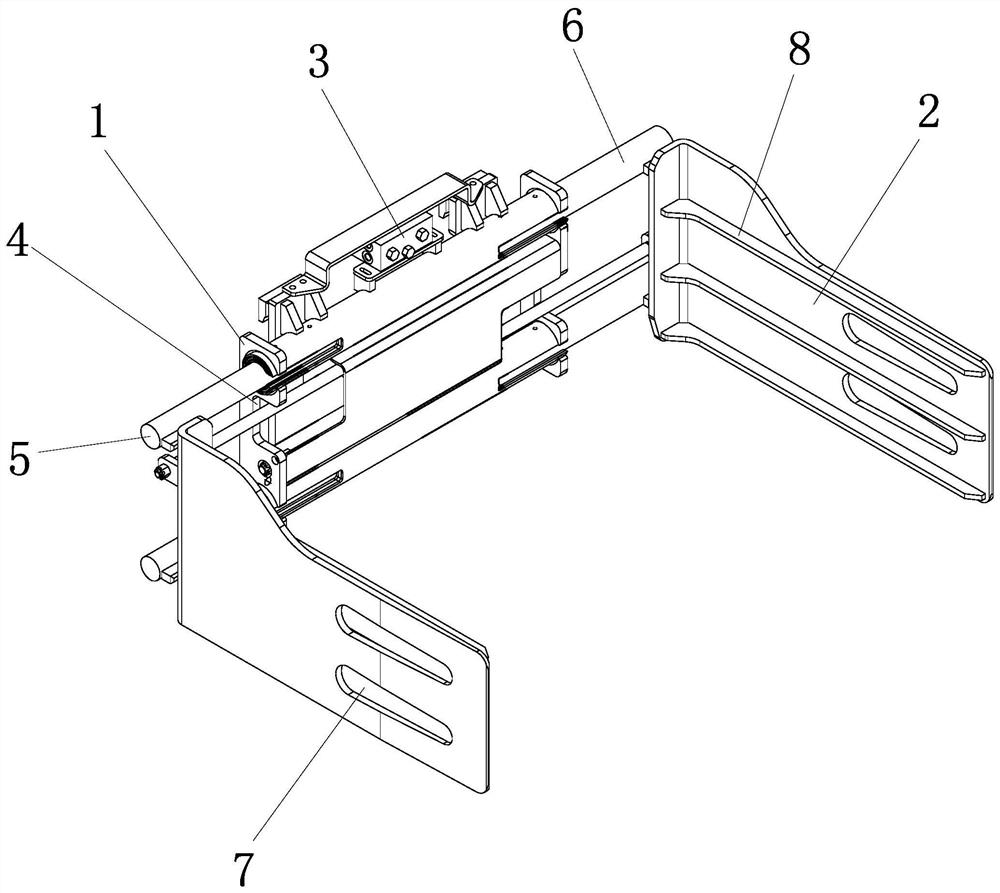

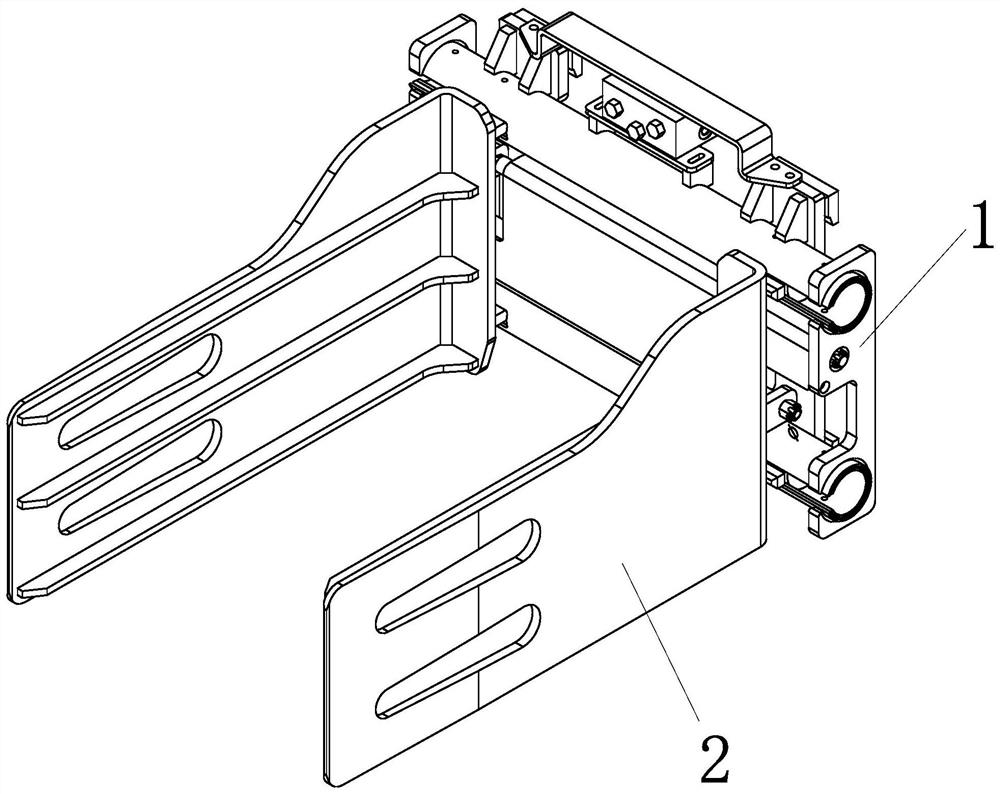

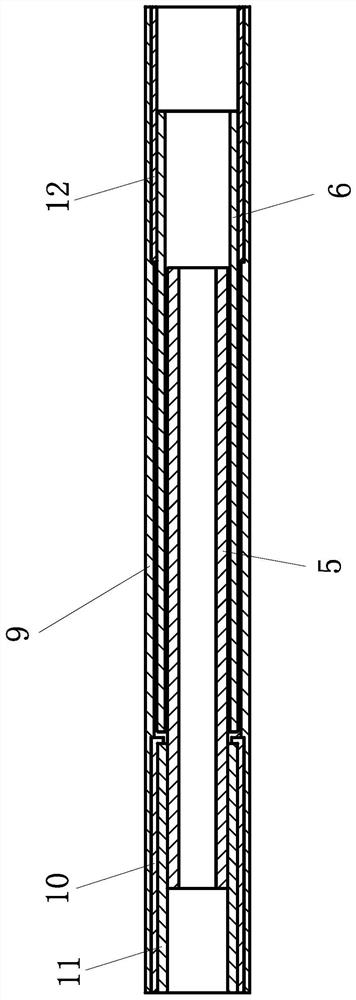

[0025] Example 1: as figure 1 , 2, 3, 4, and 5, a light-duty clip attachment includes a fixed frame 1 and a splint 2 slidably connected to both sides of the fixed frame. A guide rail is arranged inside the fixed frame, and a sliding sleeve rod assembly is arranged inside the guide rail. Each of the splints is connected with the sliding sleeve rod assembly, and the fixing frame is provided with a side shift valve group 3 for driving the sliding sleeve rod assembly to move. The sliding sleeve rod assembly includes a first fixed sleeve 9, a second fixed sleeve, a third fixed sleeve 12, a left guide rod 5 and a right guide rod 6. The second fixed sleeve is located at one end of the first fixed sleeve, and the third fixed sleeve is located on the first fixed sleeve. At the other end of a fixed sleeve, the right guide rod is located in the third fixed sleeve and is slidably connected with the third fixed sleeve, and the left guide rod is located in the second fixed sleeve and is sl...

Embodiment 2

[0027] Embodiment 2: The structure of this embodiment is basically the same as that of Embodiment 1, and the difference is that, such as Image 6 , 7 As shown, the end of the right guide rod close to the left guide rod is provided with a flared portion 14 with a diameter larger than that of the right guide rod. The outer sleeve of the mouth is provided with a sheath 15, the sheath is in the shape of a cone, the free end edge of the sheath is fixedly connected with the free end edge of the flared part, and the other end edge of the sheath is provided with a number of oil outlet grooves 16, the sheath Between the flaring part and the flaring part is an accommodating cavity. The accommodating cavity is embedded with an elastic sleeve 17, a tough sleeve 19 and an oil-absorbing cotton 18. The inner surface of the elastic sleeve is fitted with the outer surface of the flaring part, and the outer surface of the flexible sleeve and the inner surface of the sheath are fitted. Fittingl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com