Adjusting valve

A technology for regulating valves and valve bodies, applied in the field of regulating valves, which can solve the problems of valve leakage, unstable operation, and short service life, and achieve the effects of avoiding pressure loss, avoiding disc vibration, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the drawings and specific embodiments. It should be noted that in the drawings or descriptions, similar or identical parts use the same figure numbers, and implementations that are not shown or described in the drawings The method is a form known to those of ordinary skill in the art. In addition, the directional terms mentioned in the embodiments, such as "upper", "lower", "top", "bottom", "left", "right", "front", "rear", etc., are only for reference to the accompanying drawings. The directions are not intended to limit the protection scope of the present invention.

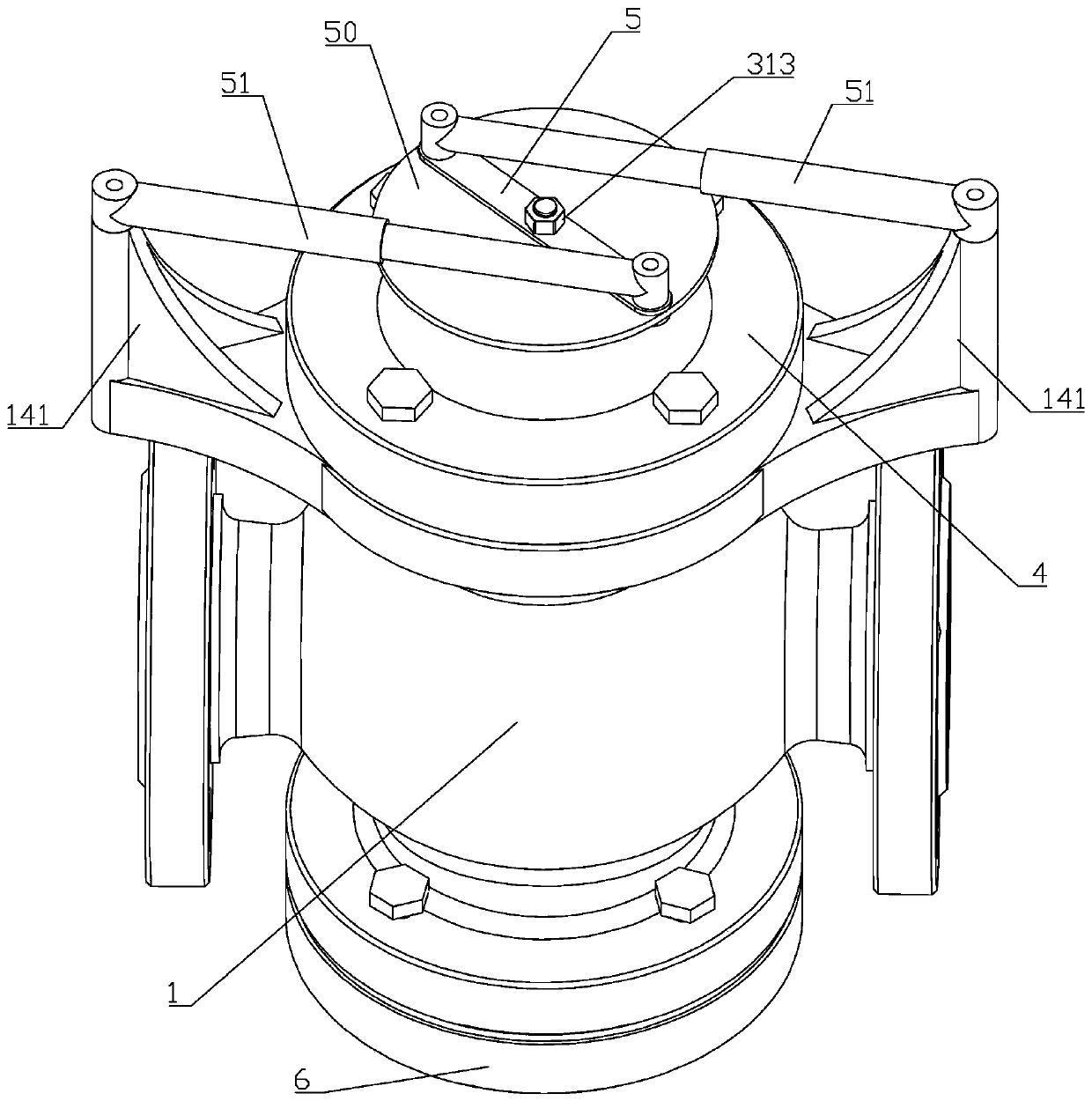

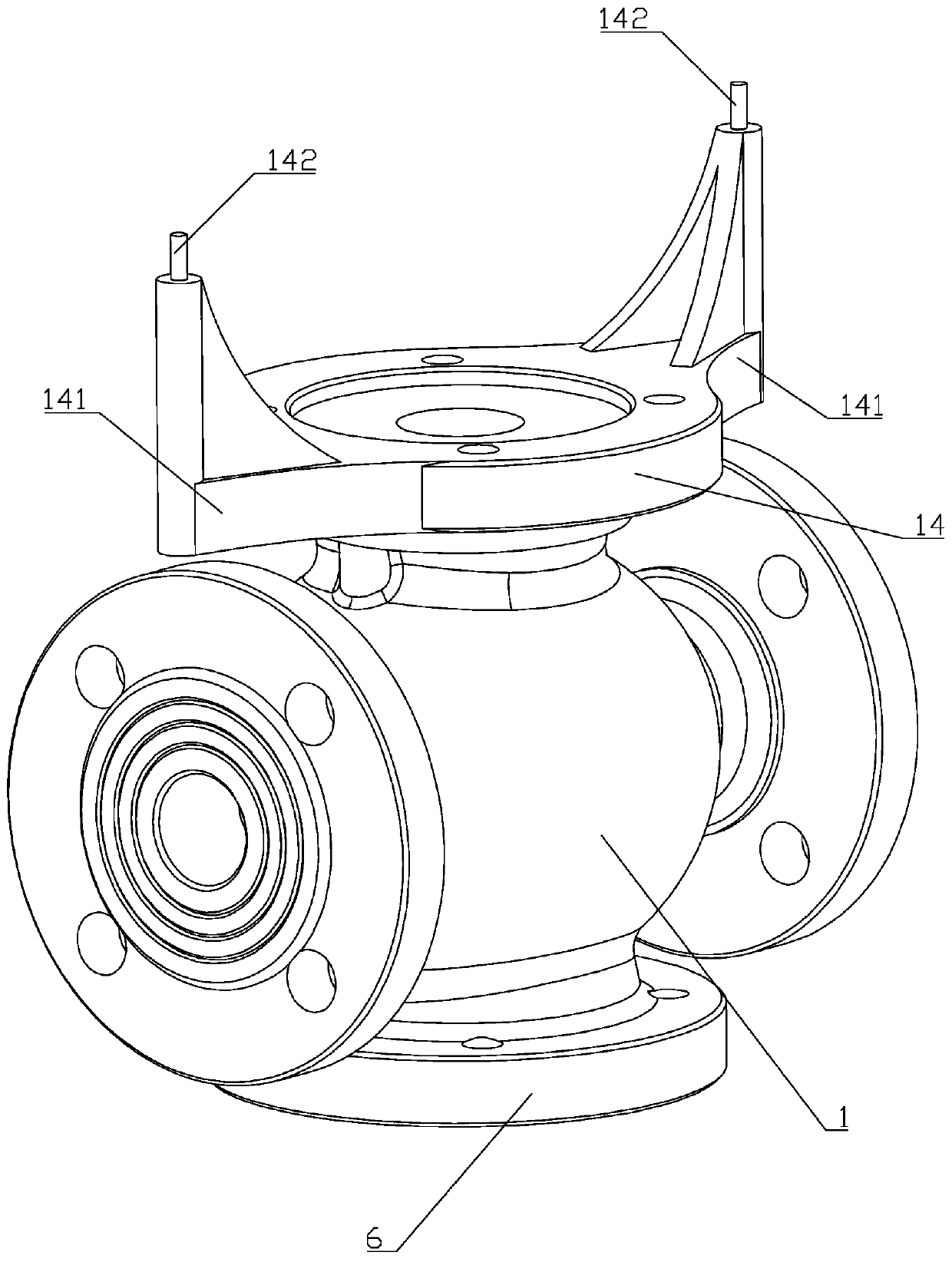

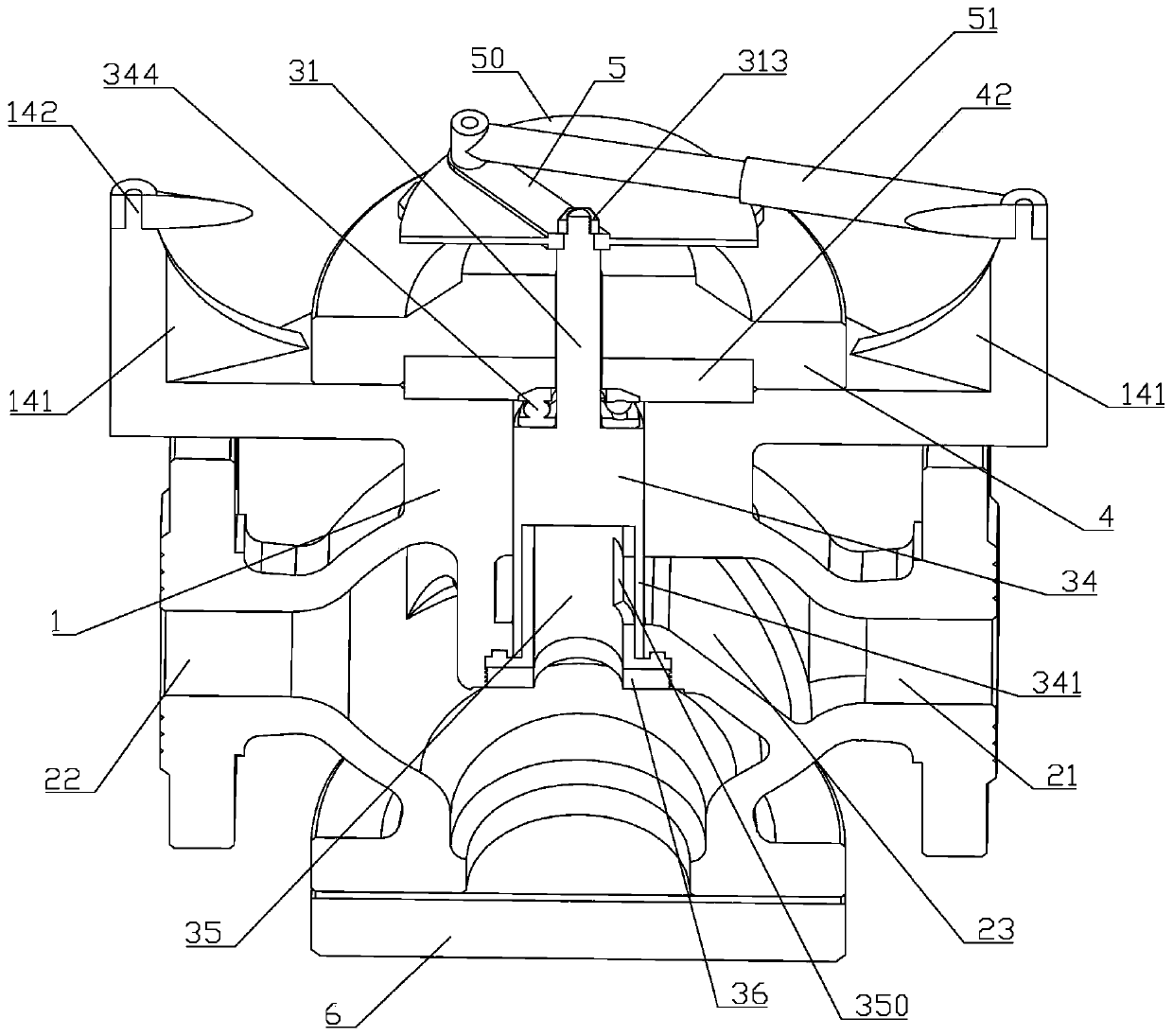

[0042] Such as Figure 1 to Figure 11As shown, a regulating valve of this embodiment includes a valve body 1, a valve core 31 and a valve cover 4, the valve cover 4 is fixedly installed on the valve body 1, and the valve body 1 is provided with an air inlet 21 and an exhaust port. 22. The valve body 1 includes an upper valve ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com